Flexible grinding head device of pneumatic grinding machine

A technology of elastic device and grinding head, which is applied in the direction of grinding/polishing safety device, grinding machine tool parts, grinding/polishing equipment, etc. It can solve the problems of increasing labor intensity, grinding head wear, and high technical requirements for workers. Achieve the effect of improving machining accuracy and efficiency and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

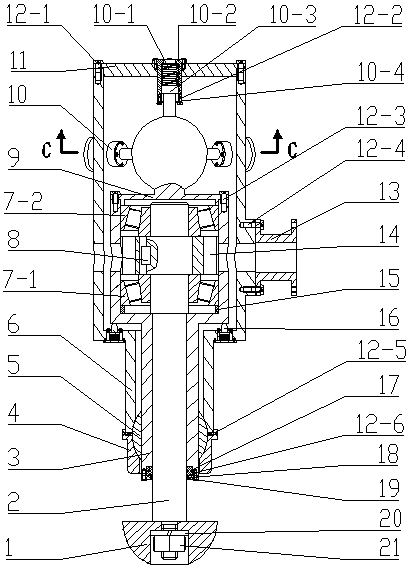

[0014] Embodiment 1, which includes a main shaft 2, a sleeve 3, a sleeve rear end cover 9, and a casing 6; a grinding head 1 is installed at the front end of the main shaft 2, and a spring washer 20 and a nut 21 are installed in turn for fixing the grinding head 1. The wind wheel 14, bearings 7-1 and 7-2 are installed on the rear end of the main shaft 2, and the other side of the bearings 7-1 and 7-2 is also installed with a retaining ring 15 and a sleeve rear end cover 9; There are two corresponding holes on the cylinder 3 and the box body 6, one through the through hole formed by the connection between the connecting frame 13 and the box body 6 to enter the high-pressure air, and the other to exhaust, the input high-pressure air drives the wind wheel 14 to rotate, and the main shaft 2 The output drives the grinding head 1 to rotate; the front end of the sleeve 3 is fitted with a spherical bushing 5, and the spherical bushing 5 is assembled on the box body 6 through the solid ...

Embodiment 2

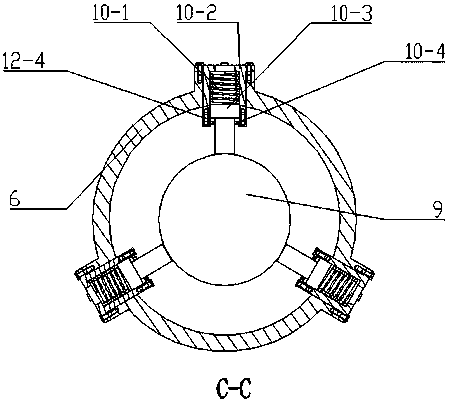

[0015] Embodiment 2, three elastic devices 10 are installed on the box body 6, and the distance between these three elastic devices 10 is 120°. An elastic device 10 is installed on the end cover of the box body 6, and the four The elastic device is in point contact with the spherical contour at the end of the sleeve rear end cap 9 . When the grinding head 1 encounters the impact point of the processing surface or performs processing compensation, the main shaft 2 can rotate a certain angle around the center of the spherical bushing 5, and at the same time the main shaft 2 can also be displaced in the axial direction, and the elastic device 10 provides the reaction force, thereby Realize the flexible adjustment of the position of grinding head 1. refer to Figures 1 to 3 , all the other are with embodiment 1.

Embodiment 3

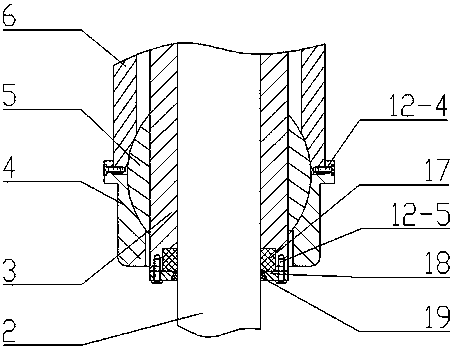

[0016] Embodiment 3, four elastic devices 16 are installed on the neck of the box body 6 , the elastic devices 16 are spaced apart by 90°, and the push rods of the elastic devices 16 are in contact with the neck of the sleeve 3 . The elastic force provided by the elastic device 16 counteracts the effect of the gravity of the sleeve 3, prevents the sleeve 3 from sliding down due to gravity, and allows the sleeve 3 to reset when the grinding machine stops. refer to Figures 1 to 3 , the rest are the same as

[0017] Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com