Composite semiconductor device and method of manufacturing the same

一种复合器件、半导体的技术,应用在半导体/固态器件制造、半导体器件、电固体器件等方向,能够解决混色的特性变差等问题,达到可靠性优异、质量稳定性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

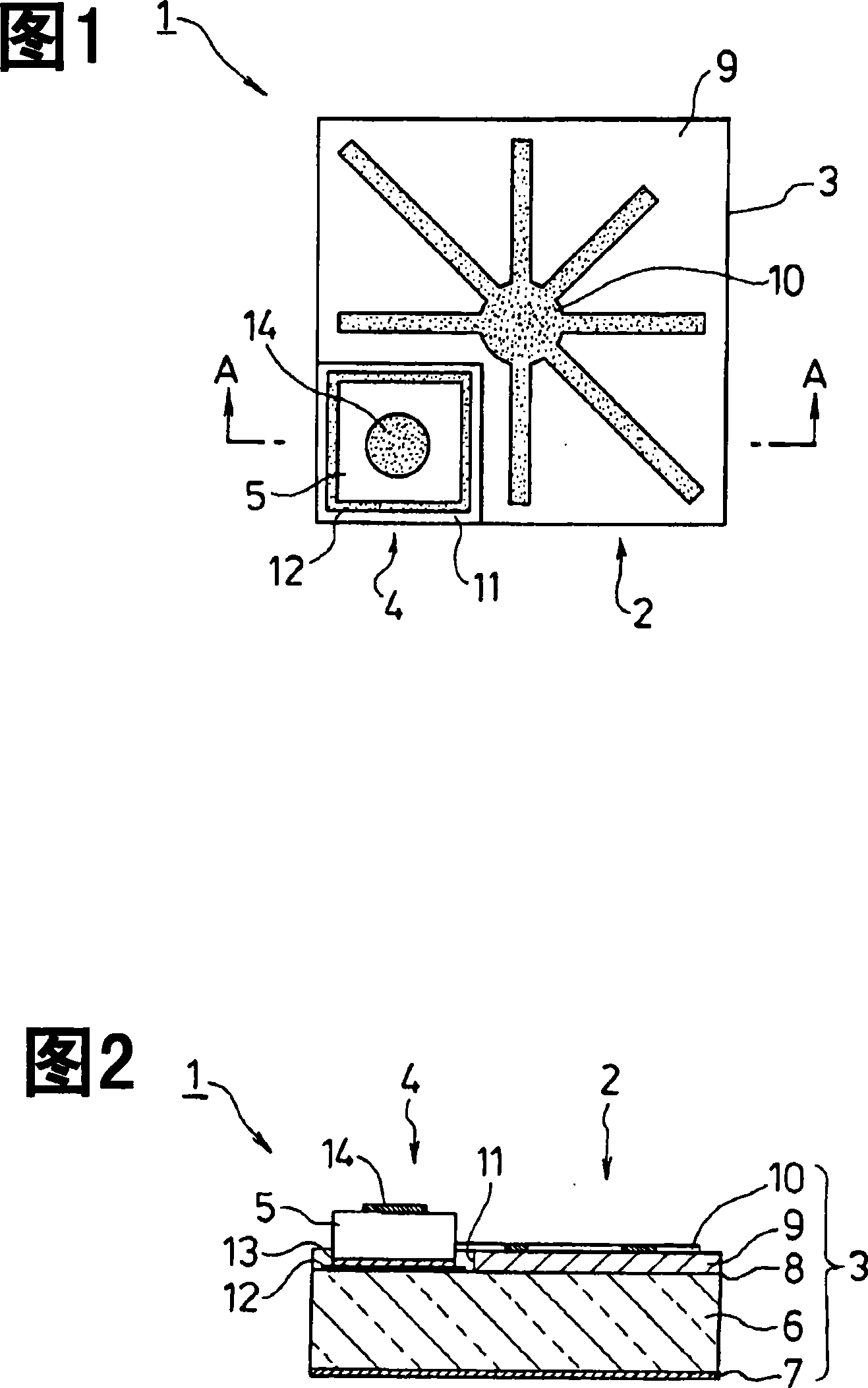

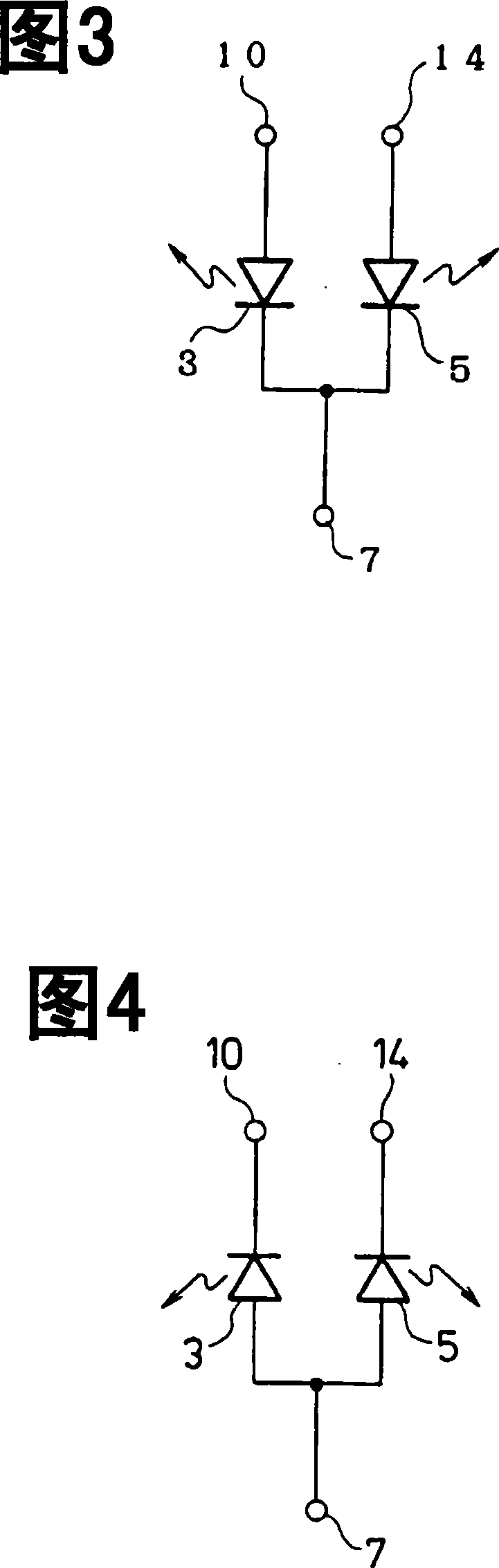

[0045] 1 is a plan view of Embodiment 1 of a semiconductor composite device according to the present invention, and FIG. 2 is a cross-sectional view along A.A of FIG. 1 .

[0046] A semiconductor composite device (semiconductor composite device, hereinafter referred to simply as "composite device") 1 includes a first semiconductor light emitting device (hereinafter referred to simply as "first light emitting device") 3 for constituting a first light emitting region 2; and a second semiconductor A light emitting device (hereinafter referred to as “second light emitting device”) 5 for constituting the second light emitting region 4 .

[0047] The first light emitting device 3 is configured as follows. The material is suitably selected from Si, Al having desired properties such as high electrical conductivity, high transmittance, high thermal conductivity and high strength 2 o 3 , SiC and GaP to form a common substrate 6 . First external connection electrodes 7 are formed on o...

Embodiment 2

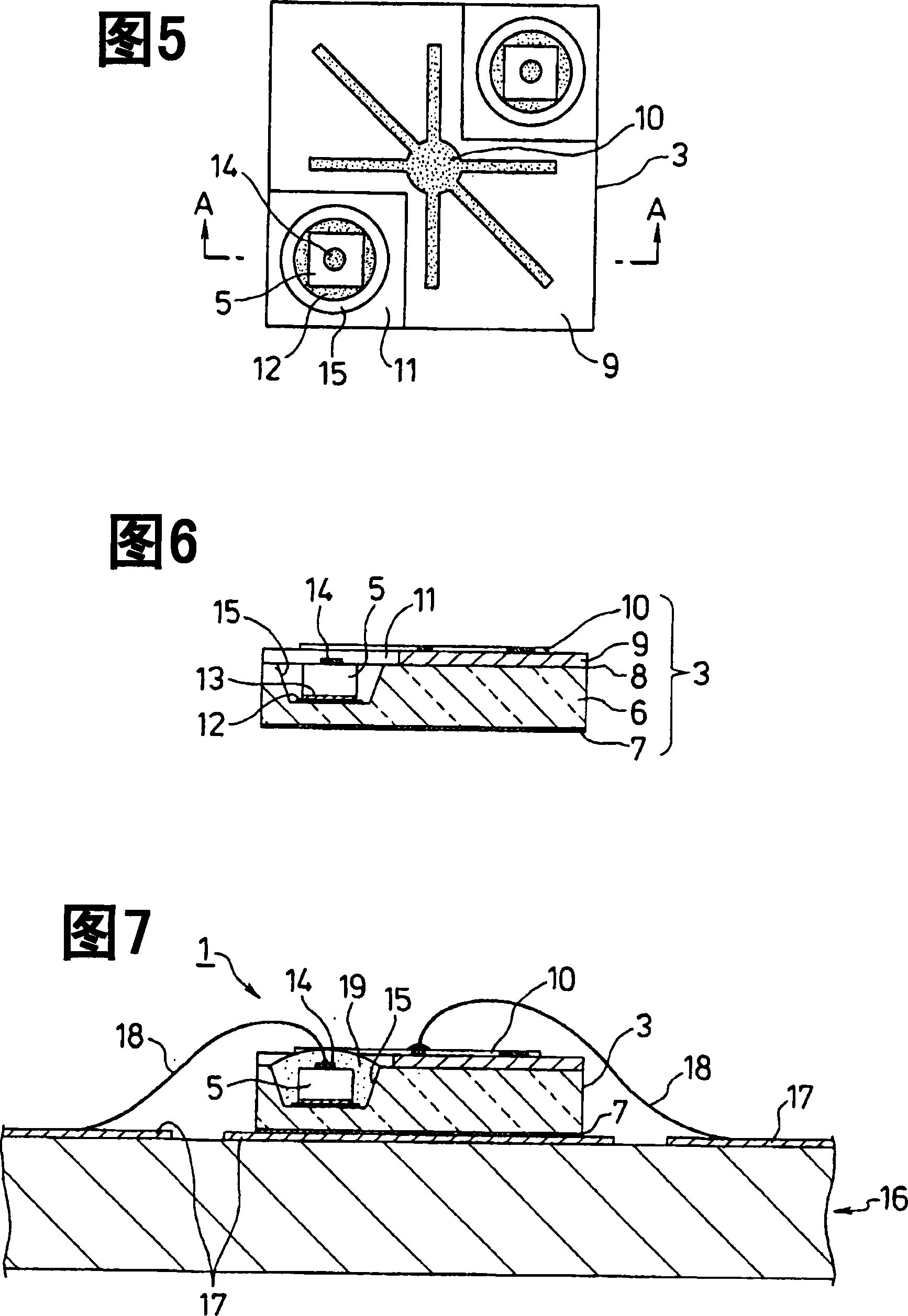

[0054] 5 is a plan view of Embodiment 2 of the semiconductor composite device according to the present invention, FIG. 6 is a cross-sectional view along A-A of FIG. 5, and FIG. 7 is an installation view.

[0055] In the present invention, corresponding grooves 11 are formed in the first light emitting device 3 at two opposite positions of the common substrate 6 where the second external connection electrode 10 and the growth layer 9 do not exist. A recess 15 is formed in the common substrate 6 in such a manner as to be exposed through the bottom of each groove 11 .

[0056] The second light emitting device bonding electrode 12 is formed on the inner bottom of the recess 15 . The eutectic junction between the lower electrode 13 on the second light emitting device 5 and the bonding electrode 12 fixes the second light emitting device 5 in the recess 15 and also enables electrical conduction between the two electrodes.

[0057] Other structures are similar to the above-mentioned ...

Embodiment 3

[0064] 8 is a sectional view of Embodiment 3 of the semiconductor composite device according to the present invention, and FIGS. 9 and 10 are mounting views.

[0065] In this embodiment 3, different from embodiment 2, the second external connection electrode 10 on the first light emitting device 3 and the upper side electrode 14 on the second light emitting device 5 have corresponding upper side surfaces on the same plane. In order to secure the positional relationship between the electrodes 10 and 14 , the first light emitting device 3 is manufactured to have a thickness greater than that of the second light emitting device 5 . In addition, the depth of the recess 15 formed in the common substrate 6 is determined in consideration of the thickness of the second light emitting device 5 .

[0066] A bumpball 28a composed of Au or the like is formed on the second external connection electrode 10, and a bump ball 28b also composed of Au or the like is formed on the second light em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com