Novel rotary kiln with three-gear-supported super-short kiln body

A technology of rotary kiln and ultra-short kiln, applied in rotary drum furnace, furnace type, furnace and other directions, can solve the problem of high transformation cost, and achieve the effect of reducing investment cost, reducing resistance and reducing residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand and illustrate the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

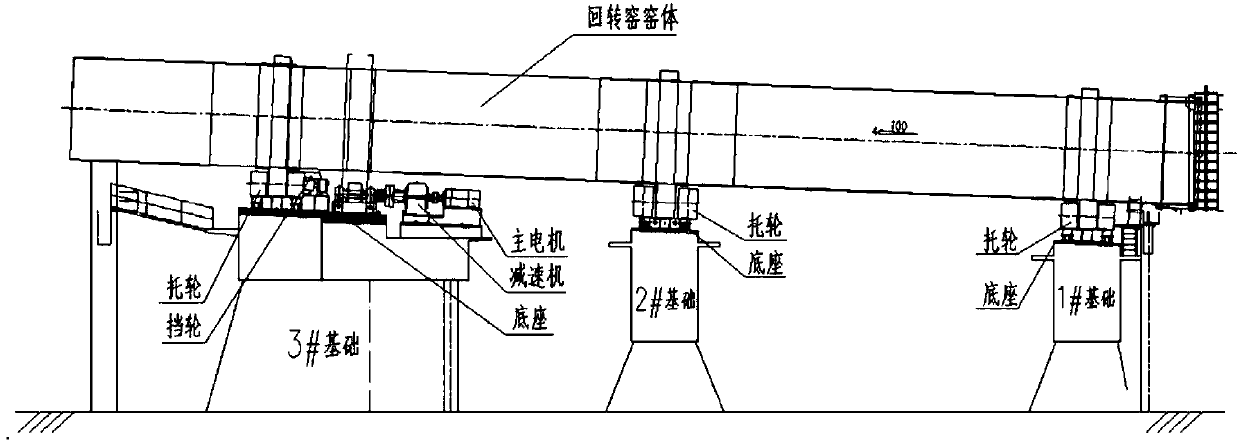

[0016] figure 1 It is a new type of rotary kiln with three gears supporting the ultra-short kiln body. The rotary kiln includes a rotary kiln body, a base and a supporting device.

[0017] Among them, the length of the rotary kiln body is 52m and the diameter is 4.6m. There are three bases and supporting devices, and the entire rotary kiln body is fixed on the three bases through three sets of supporting devices.

[0018] The supporting device includes a wheel belt, a supporting wheel and a gear wheel. The three bases are respectively located at the kiln head, the middle part and the kiln tail of the rotary kiln body, and the distance between any two bases is .

[0019] The kiln body of the rotary kiln is also provided with a main motor and a reducer. The main motor and the reducer are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com