Pre-chamber spark plug having adapted cap geometry

A geometry and pre-chamber technology, applied in spark plugs, electrical components, circuits, etc., can solve problems such as damage to combustion engines, undesired wear of hot ignition covers, electrode wear and heat accumulation, etc. The effect of avoiding heat accumulation and improving the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

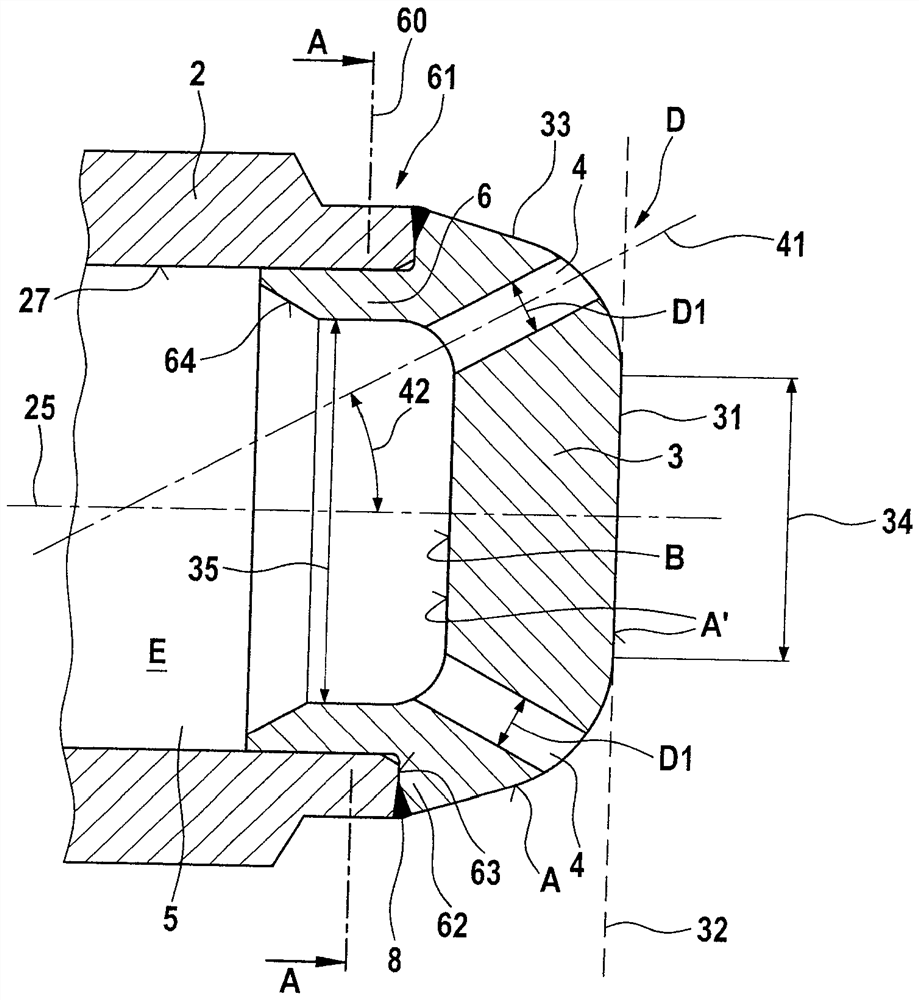

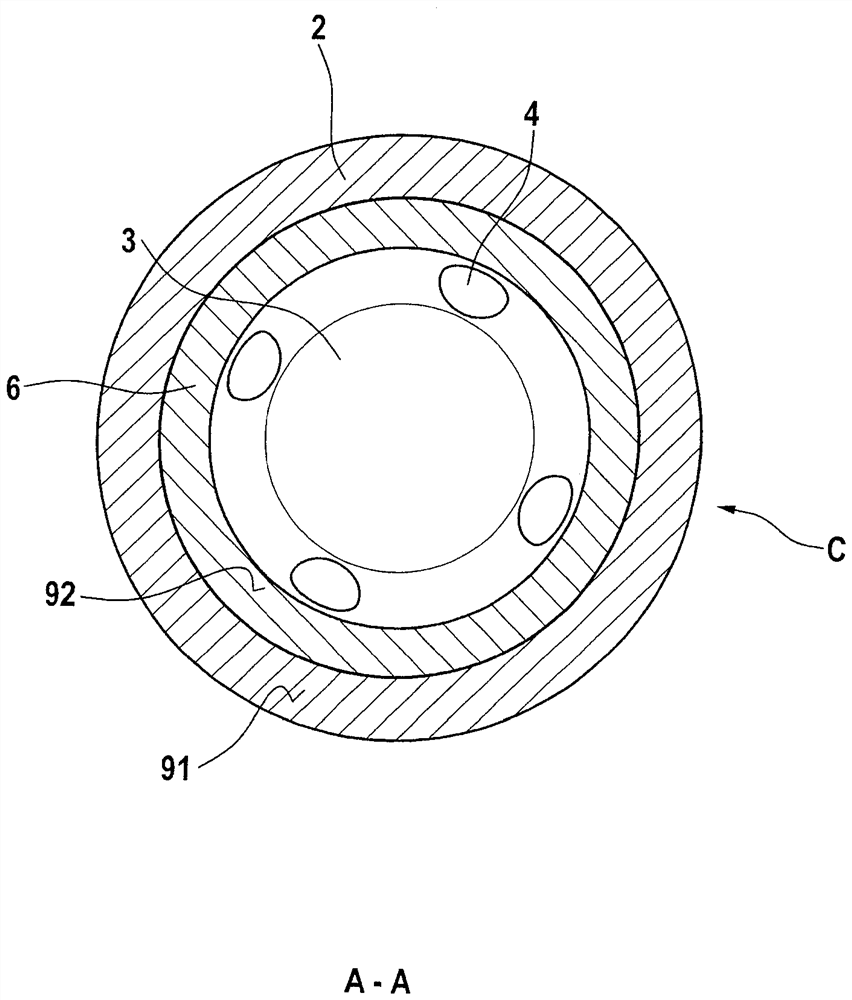

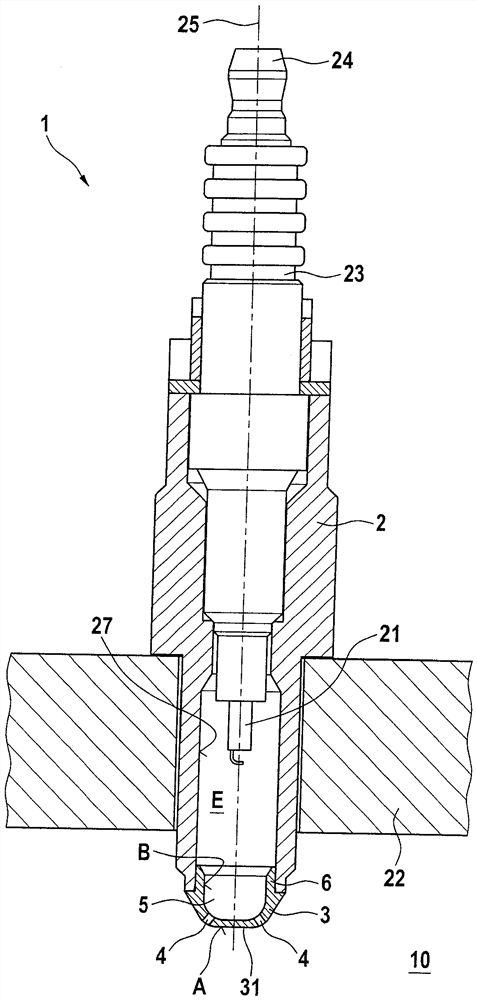

[0020] referenced below Figure 1 to Figure 3 A prechamber spark plug 1 according to a preferred exemplary embodiment of the present invention will be described in detail.

[0021] as from figure 1 As can be seen in the figure, the pre-chamber spark plug 1 includes a housing 2 and a cover 3 . The cover 3 is arranged on that end of the housing 2 facing the combustion chamber 10 . The cap 3 together with the housing 2 forms the prechamber 5 of the prechamber spark plug 1 . The pre-chamber spark plug 1 is in figure 1 is schematically shown in and furthermore has electrodes 21 , insulators 23 and electrical connections 24 .

[0022] as in figure 1As shown schematically, prechamber spark plug 1 is screwed into a cylinder head 22 of a combustion engine such that cover 3 protrudes into combustion chamber 10 . As a result, the cover 3 is directly exposed to the high temperatures in the combustion chamber 10 .

[0023] In order to be able to absorb and dissipate high temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com