Manufacturing process for low-alloy structural steel for coal mine machinery

A technology of coal mining machinery and manufacturing process, applied in the field of steel processing, can solve the problems of poor mechanical performance, poor low temperature performance, and short service cycle of coal mines, achieve excellent structural performance, improve toughness, and meet the effects of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

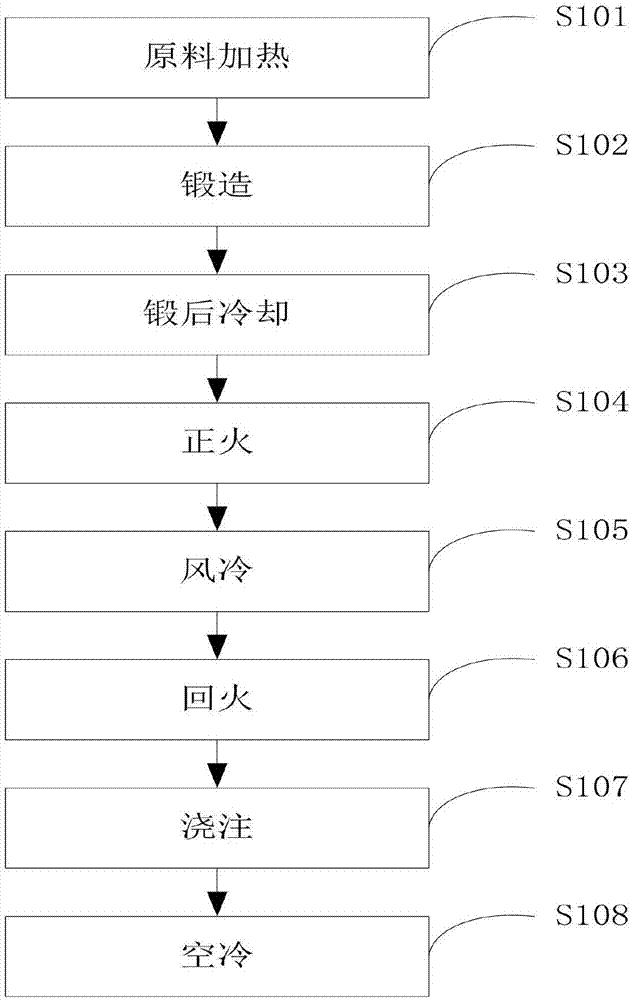

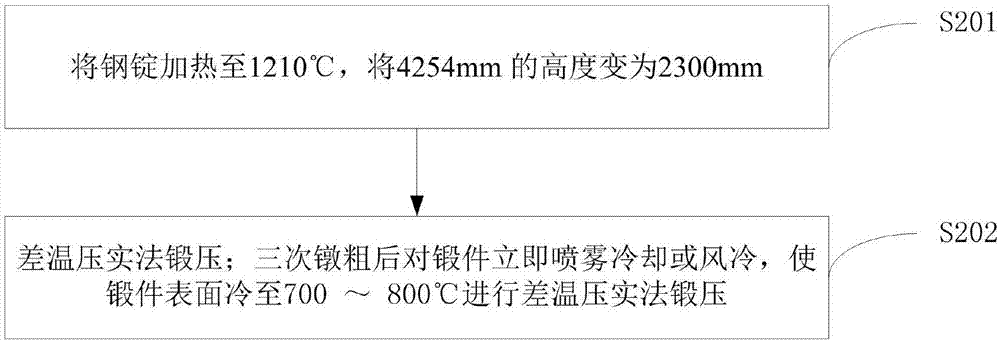

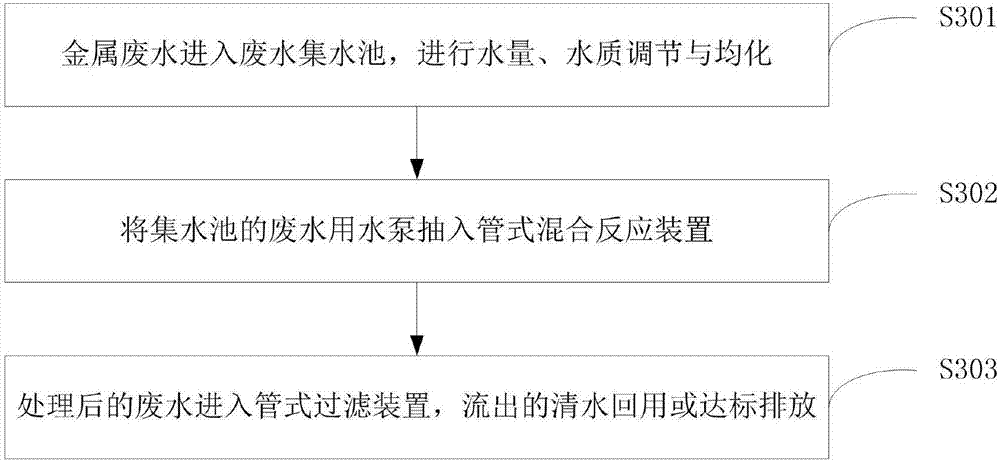

[0030] Attached below figure 1 To attach image 3 and specific embodiments to further describe the application principle of the present invention.

[0031] The manufacturing process of the low-alloy structural steel for coal mine machinery includes the following steps:

[0032] S101. Heating the raw material of low alloy steel, heating at 2010°C for 40min in an intermediate frequency furnace;

[0033] S102, forging, using a 2500-ton precision forging machine for forging, the drawing speed of each pass is controlled at 5 m / min, and the last drawing speed is controlled at 3 m / min;

[0034] S103, cooling after forging, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com