Separately precast and assembled bent cap and construction technology

A technology of prefabricated assembly and construction technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., which can solve the problems of negative impact, short construction period, and less workload, and achieve weight reduction, short construction period, and small environmental impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

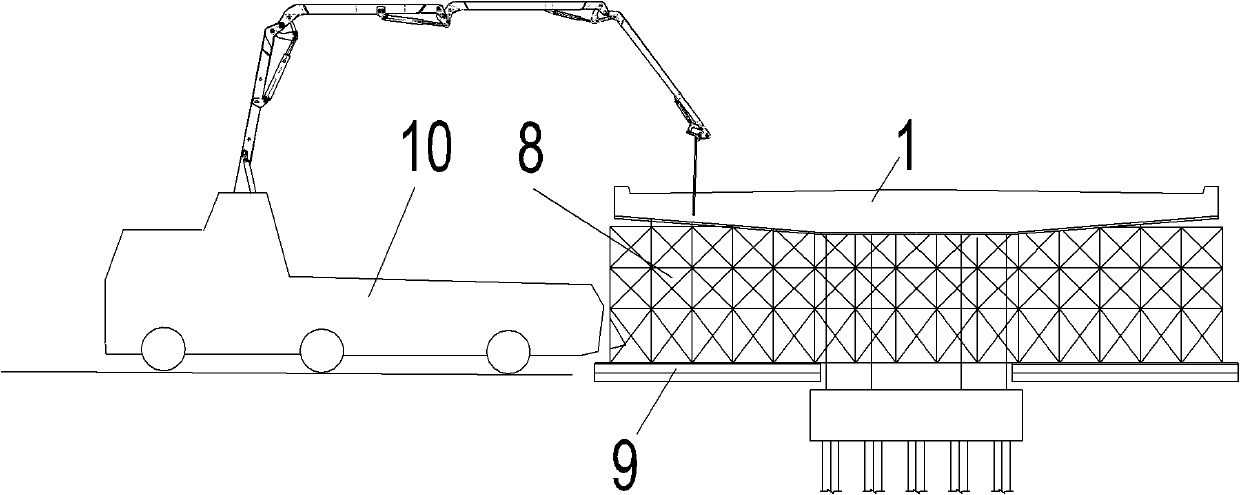

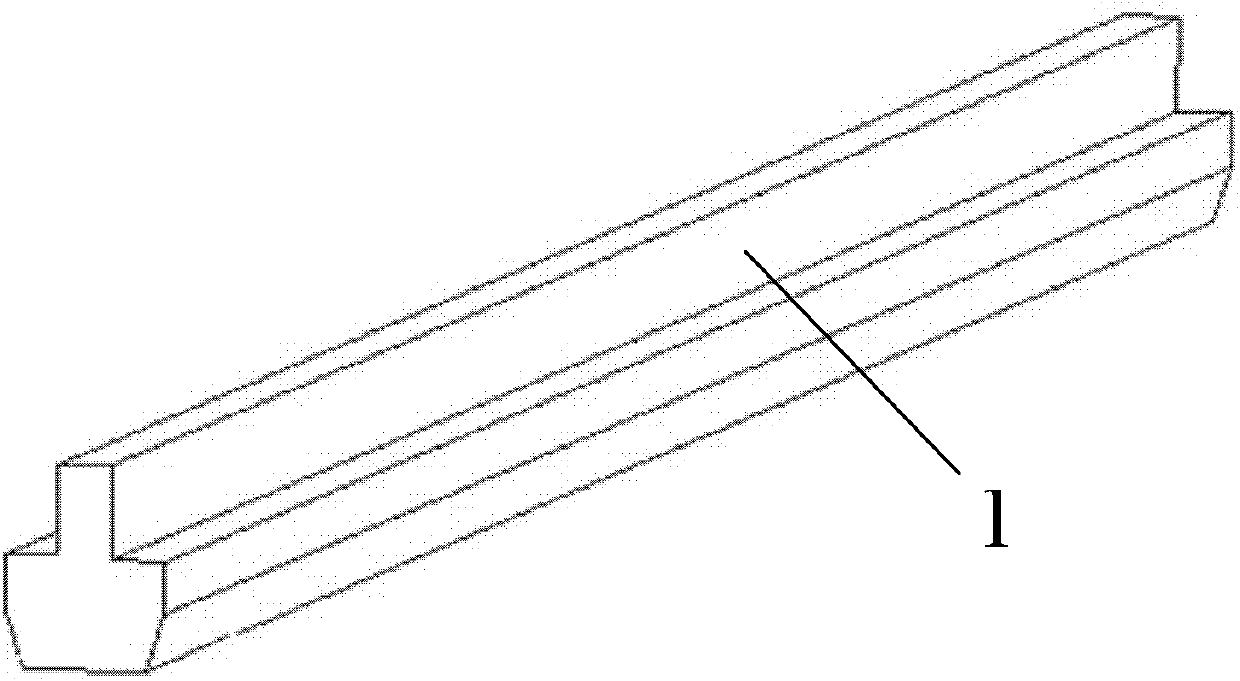

[0035] see figure 2 As shown, the designed cover beam 1 in the prior art is limited in transportation and installation due to its heavy weight.

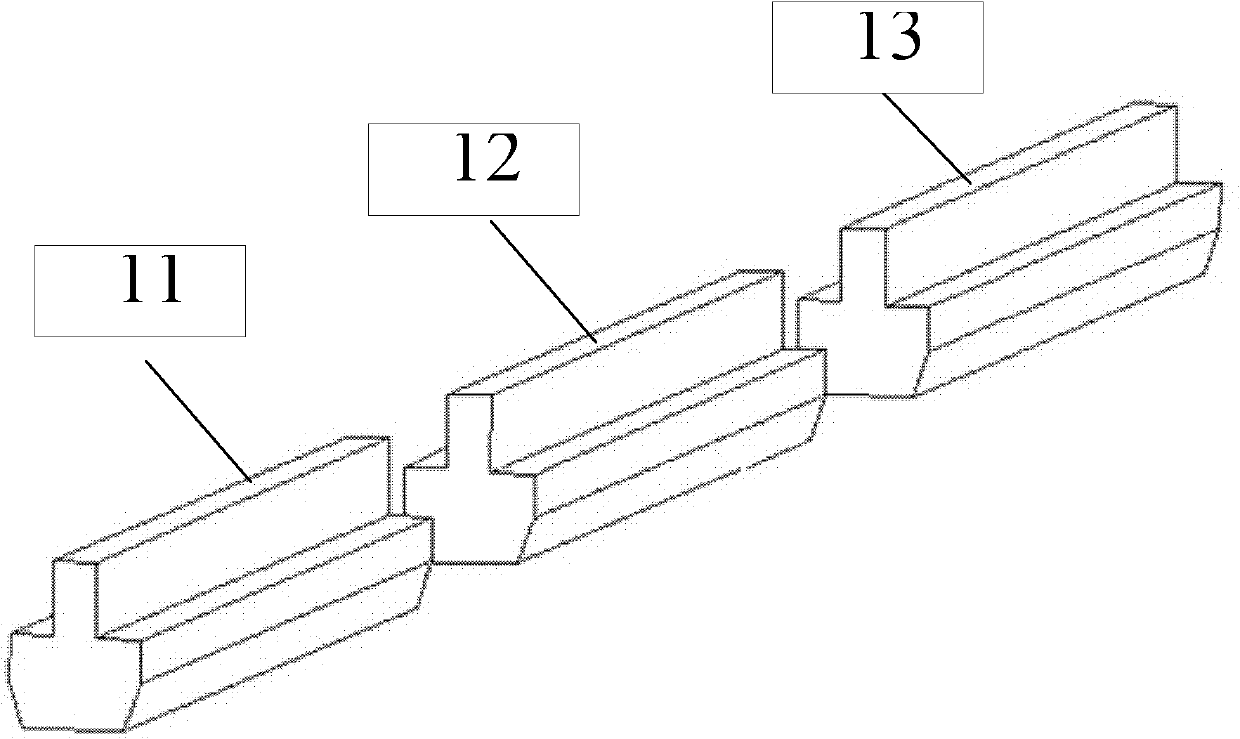

[0036] Using the design concept of the present invention, such as Figure 5 As shown, in a specific embodiment of the prefabricated and assembled cover girder in pieces of the present invention, a plurality of prefabricated components for assembling the cover girder 1 are included.

[0037] In this embodiment, the cover beam 1 is in an inverted T shape.

[0038] The prefabricated components are specifically the multi-piece prefabricated cover beams 14 and 15 formed by dividing the cover beam 1 along the length direction. The length of the sliced prefabricated cover beams 14, 15 is the same as that of the cover beam 1, and the pier column of the cover beam 1 can be directly used as a construction support when hoisting.

[0039] When assembling the prefabricated cover beams 14 and 15 in pieces, a prestressed connection method is ...

Embodiment 2

[0042] The construction technology of the sliced prefabricated assembled cap beam of the present invention comprises the following steps:

[0043] Step 1: pouring a plurality of prefabricated cap beams in pieces at the prefabrication site, and applying a certain prestress.

[0044] Step 2, transporting the multi-piece prefabricated cap beams obtained in Step 1 to the construction site.

[0045] Step 3, using hoisting equipment, hoisting a plurality of prefabricated cover girders in pieces on the pier column respectively at the construction site.

[0046] Step 4, using a fixed connection method, the multi-segmented prefabricated cover beams in step 3 are fixedly connected by a prestressed fixed connection method to form a cover beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com