Silencer for single cylinder diesel capable of reducing noise and emission and manufacturing method of silencer

A diesel engine and muffler technology, applied in mechanical equipment, machines/engines, sound absorption, etc., can solve problems such as low productivity, difficulty in meeting requirements, rough work, etc., and achieve the effects of increased productivity, good quality reliability, and improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

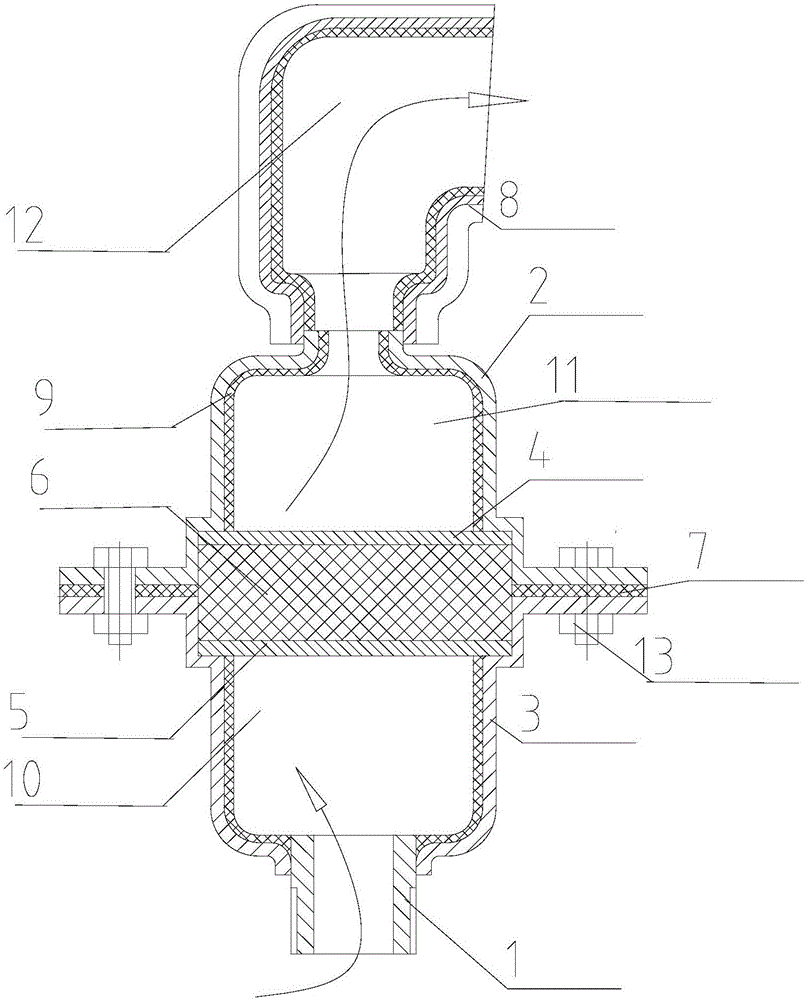

[0042] Such as figure 1 As shown, it is a single-cylinder diesel muffler for noise reduction and emission reduction in accordance with the present invention, comprising: pipe joint 1, upper casing 2, lower casing 3, upper silencing net 4, lower silencing net 5, filter body 6, Vibration isolation pad 7, exhaust pipe 8 and sound-absorbing material layer 9, wherein one end of said pipe joint 1 is connected to the exhaust elbow on the engine cylinder head by thread, and the other end is fixedly connected with said lower housing 3, said A groove body is arranged between the lower casing 3 and the upper casing 2, and the exhaust pipe 8 is necked and connected with the mouth of the upper casing 2; Net 4, the lower end of which is provided with the lower silencing net 5, and the two ends of the filter body 6 are respectively provided with vibration isolation pads 7 extending outward; the filter body 6, the upper silencing net 4 and the lower silencing net The nets 5 are all arranged ...

Embodiment 2

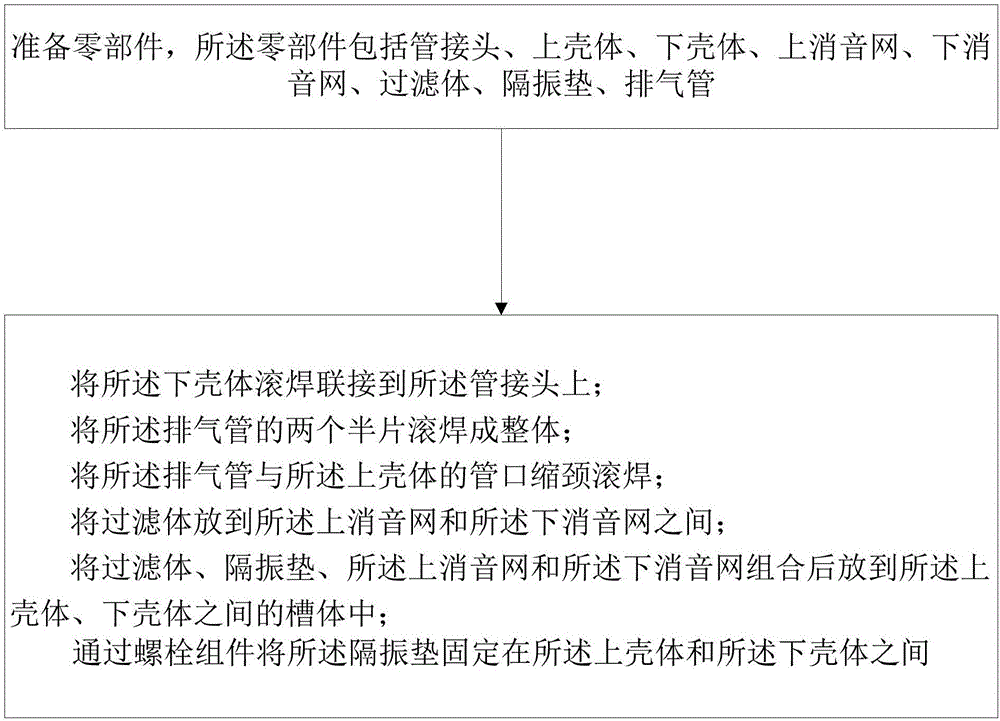

[0058] Such as figure 2 Shown, be a kind of preparation method of the single-cylinder diesel muffler based on embodiment 1 noise reduction and emission reduction, comprise the steps:

[0059] S1: Prepare parts, which include pipe joint 1, upper shell 2, lower shell 3, upper silencer net 4, lower silencer net 5, filter body 6, vibration isolation pad 7, exhaust pipe 8;

[0060] S2: Seam welding the lower shell 3 to the pipe joint 1;

[0061] Seam welding the two halves of the exhaust pipe 8 into a whole;

[0062] Neck seaming welding of the exhaust pipe 8 and the nozzle of the upper casing 2;

[0063] The filter body 6 is placed between the upper silencing net 4 and the lower silencing net 5;

[0064] Put the filter body 6, the vibration isolation pad 7, the upper silencing net 4 and the lower silencing net 5 into the tank between the upper shell 2 and the lower shell 3;

[0065] The vibration isolation pad 7 is fixed between the upper shell 2 and the lower shell 3 by a bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com