A kind of muffler of multi-stage compound noise reduction and preparation method thereof

A muffler and muffler cover technology, which is applied in the direction of mufflers, mechanical equipment, machines/engines, etc., can solve the problems of rough production quality, low productivity, and unsightly appearance, so as to reduce interference and damage, increase productivity, and improve appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

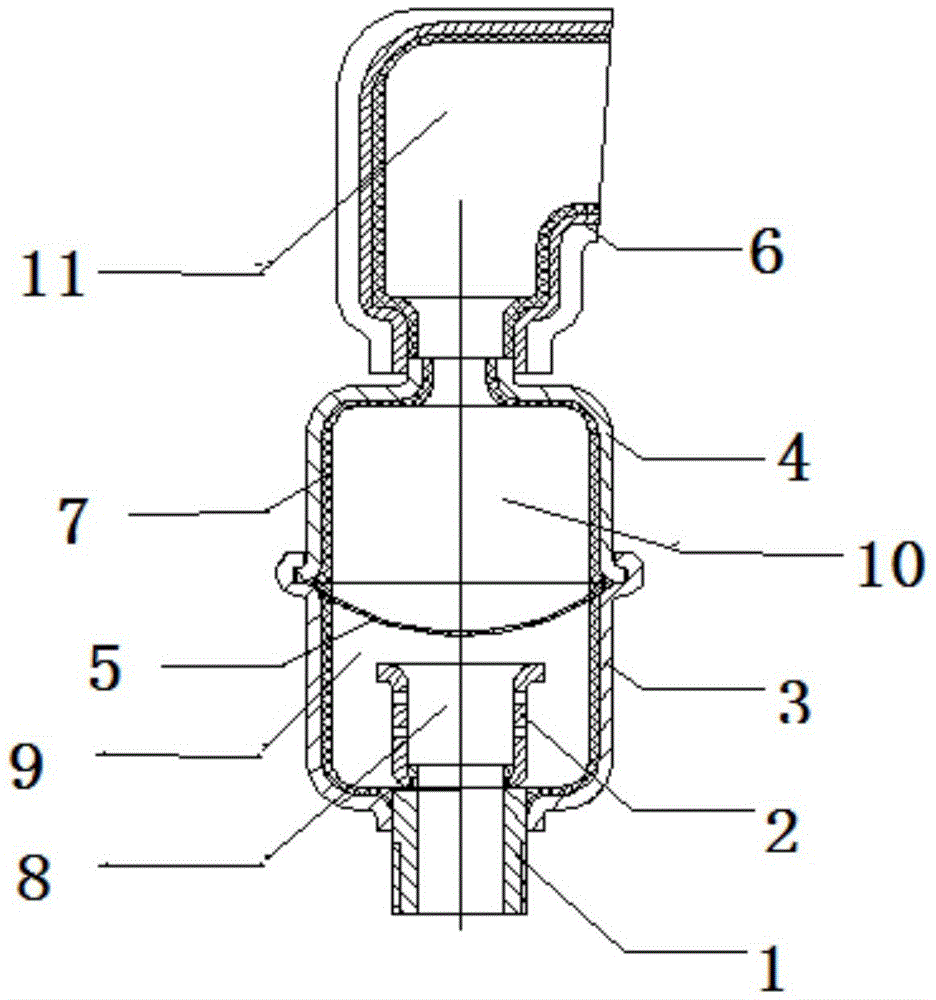

[0036] Such as figure 1 As shown, it is a multi-stage composite sound-absorbing muffler according to this embodiment, including a pipe joint 1, a sound-absorbing cover 2, a lower casing 3, an upper casing 4, a sound-absorbing net 5, an exhaust pipe 6 and a sound-absorbing material 7, The pipe joint 1 is connected to the exhaust elbow on the cylinder head of the engine, and the muffler cover 2 and the lower housing 3 are respectively connected to the pipe joint 1. There are small holes on the side wall of the muffler cover 2, The lower casing 3 is connected to the upper casing 4, the noise reduction net 5 is fixed between the upper casing 4 and the lower casing 3, and the upper casing 4 is located on the noise reduction mesh 5 above, the lower housing 3 is located below the silencing net 5, the silencing net 5 is convex to the direction of the silencing cover 2, the silencing net 5 has small holes arranged in high density, and the exhaust The pipe 6 is necked and connected to ...

Embodiment 2

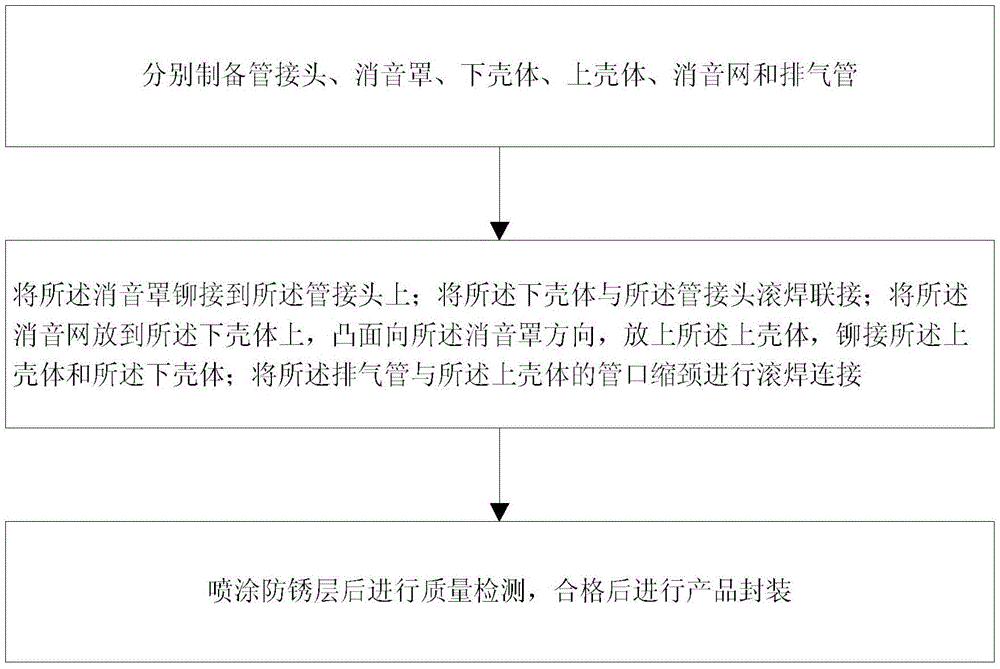

[0044] Such as figure 2 As shown, the preparation method of a multi-stage composite sound-absorbing muffler according to this embodiment includes the following steps:

[0045]S1: Prepare pipe joints, mufflers, lower shells, upper shells, mufflers and exhaust pipes respectively;

[0046] S2: riveting the noise reduction cover to the pipe joint;

[0047] seam-welding the lower shell to the pipe joint;

[0048] Put the sound-absorbing net on the lower shell, with the convex facing the direction of the sound-absorbing cover, place the upper shell, and rivet the upper shell and the lower shell;

[0049] seam-welding the exhaust pipe to the nozzle constriction of the upper casing;

[0050] S3: Conduct quality inspection after spraying the anti-rust layer, and package the product after passing the test.

[0051] The preparation method of the muffler with multi-stage compound noise reduction described in this embodiment uses the riveting and rolling welding process instead of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com