Patents

Literature

74results about How to "Improve laser absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

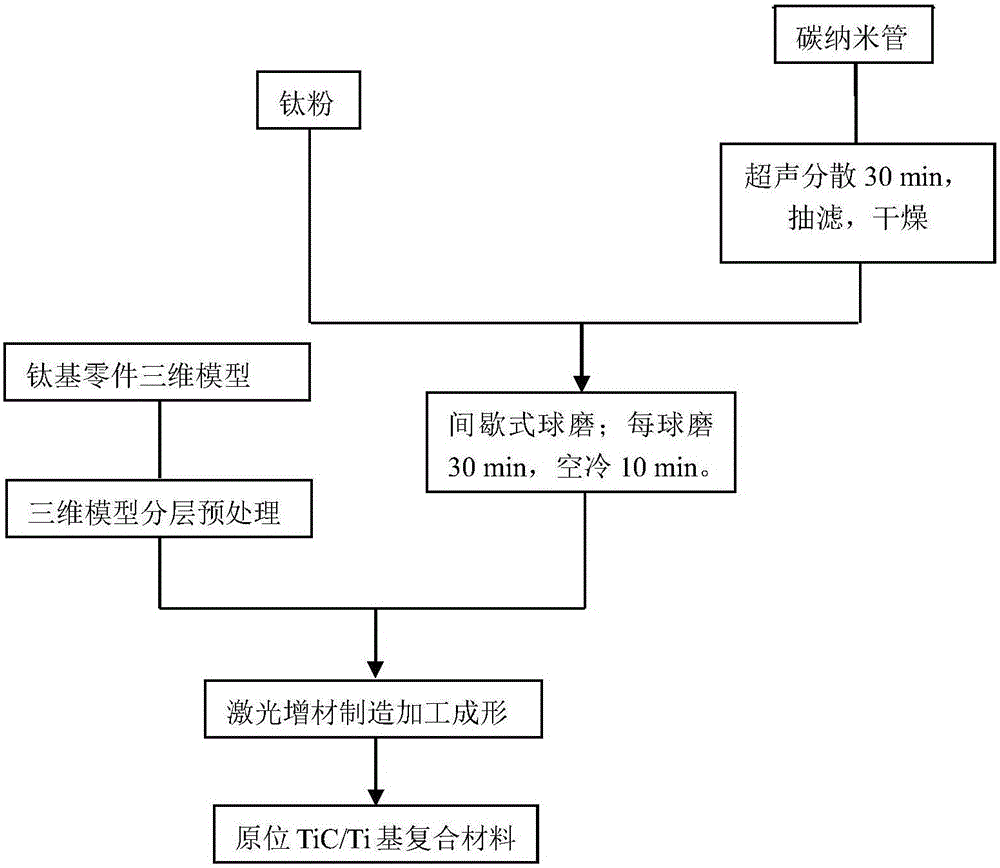

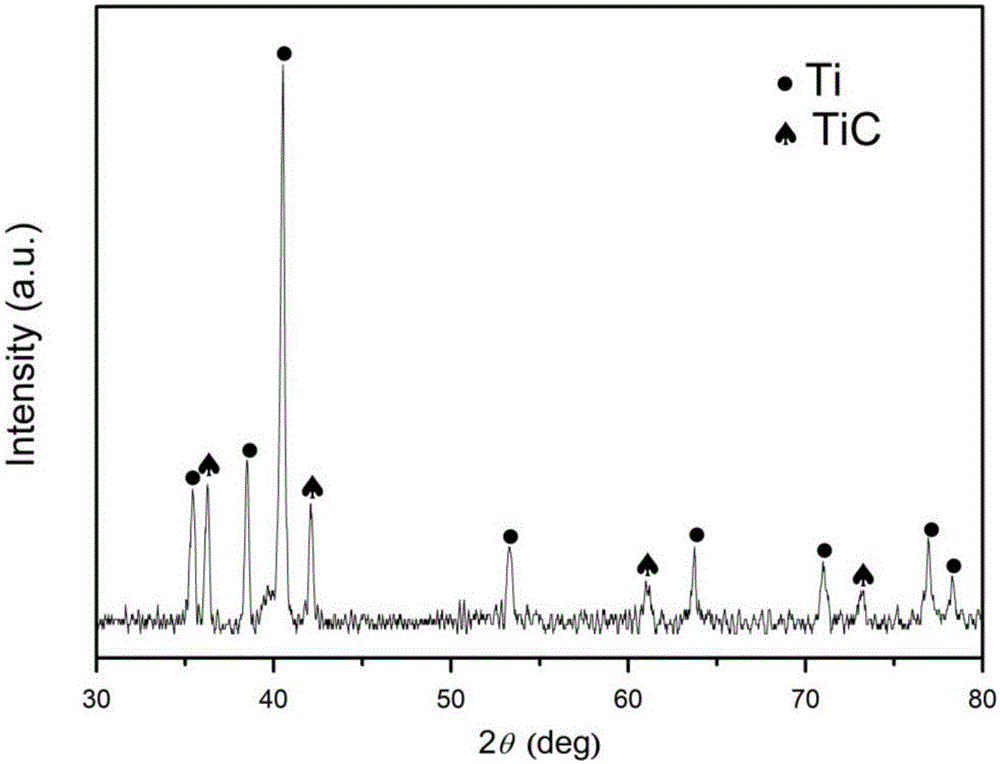

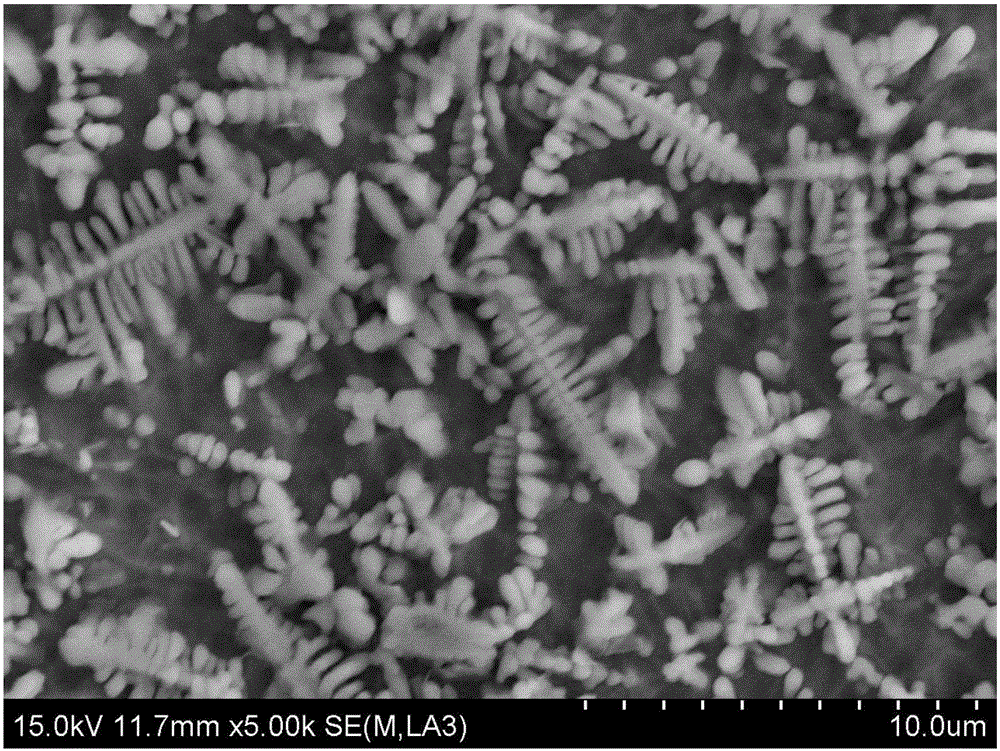

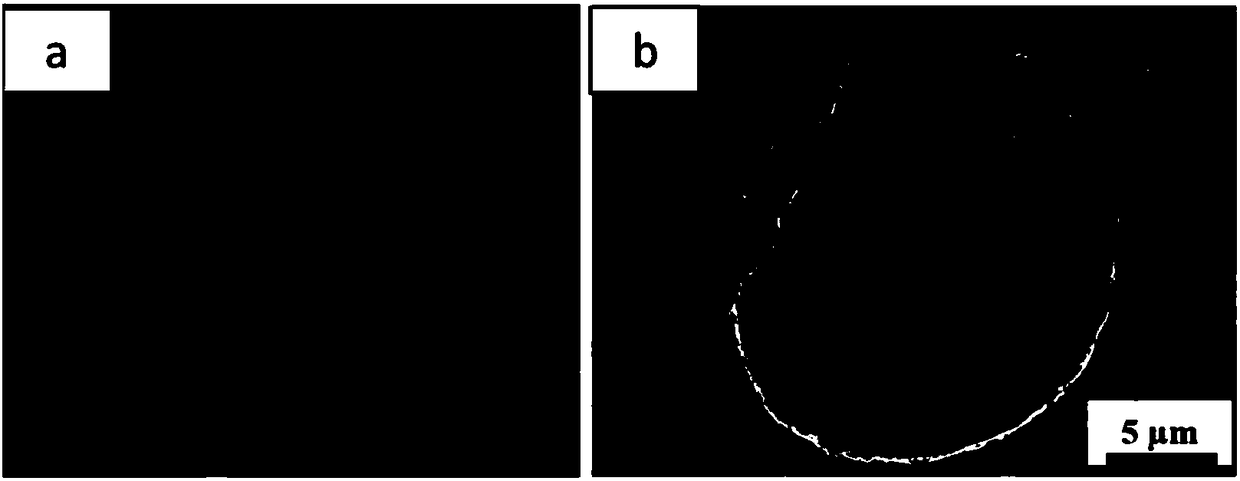

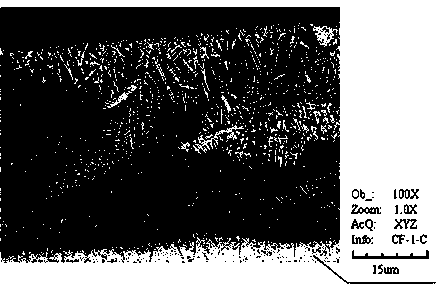

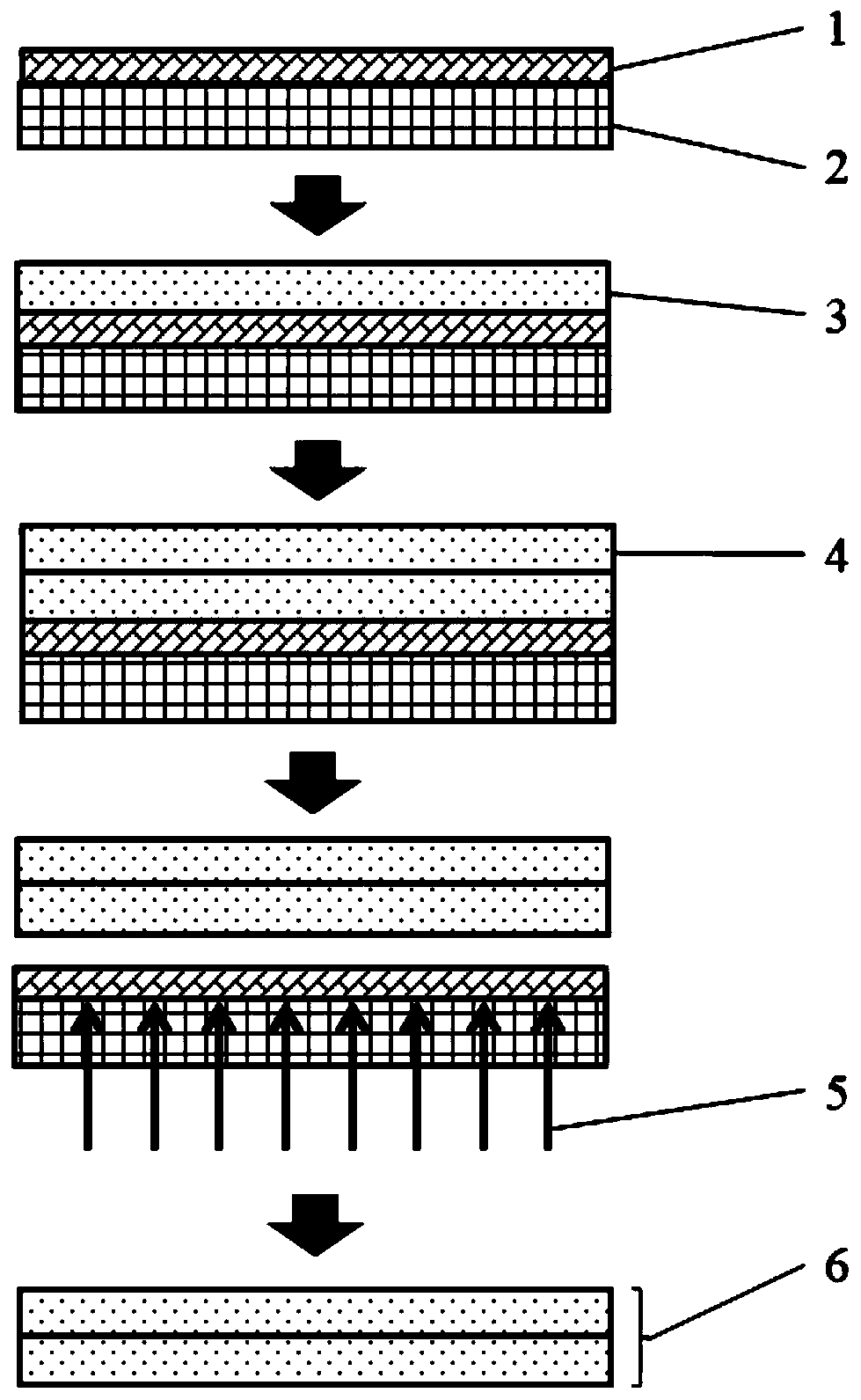

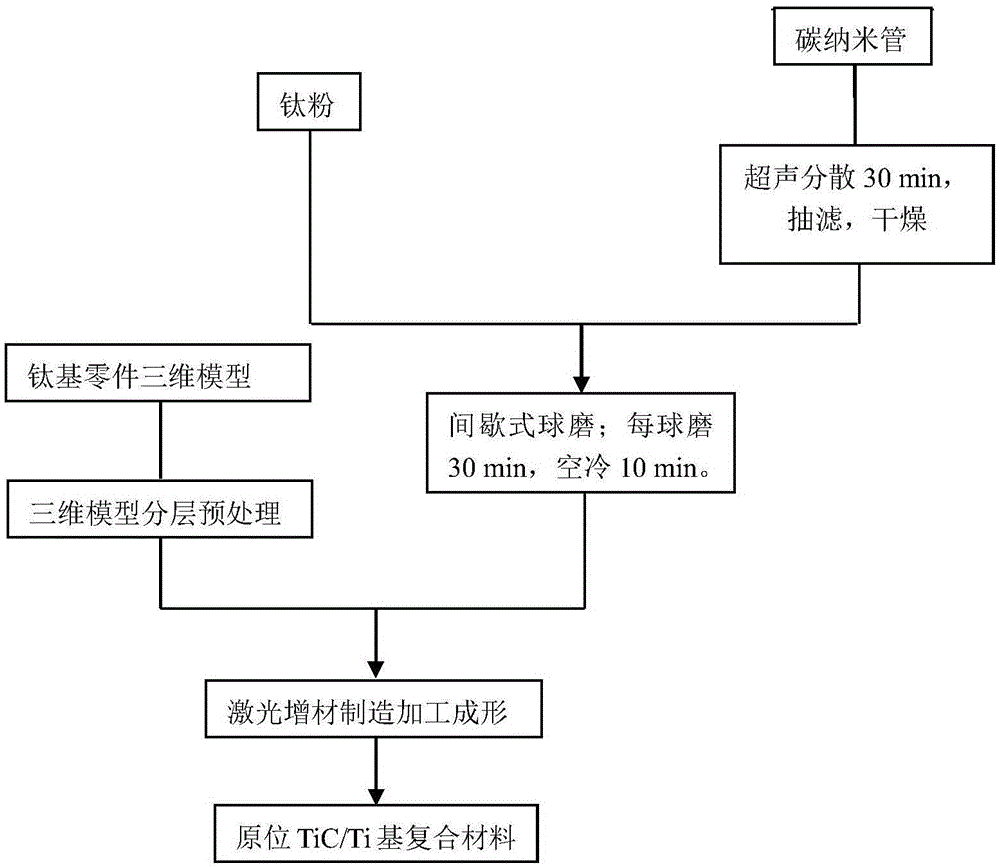

Method for manufacturing high-performance in-situ TiC reinforced titanium-based composite workpiece on basis of CNTs and laser additive manufacturing and processing technology

ActiveCN105033254AGood interface wettabilityTightly boundAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesCarbon nanotube

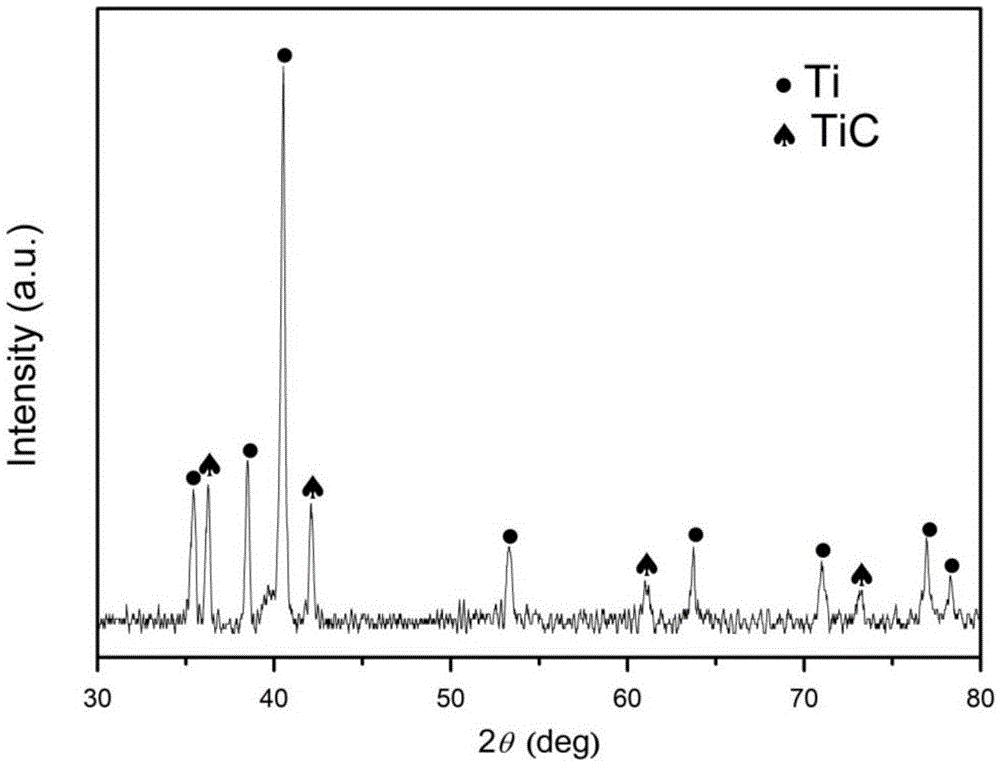

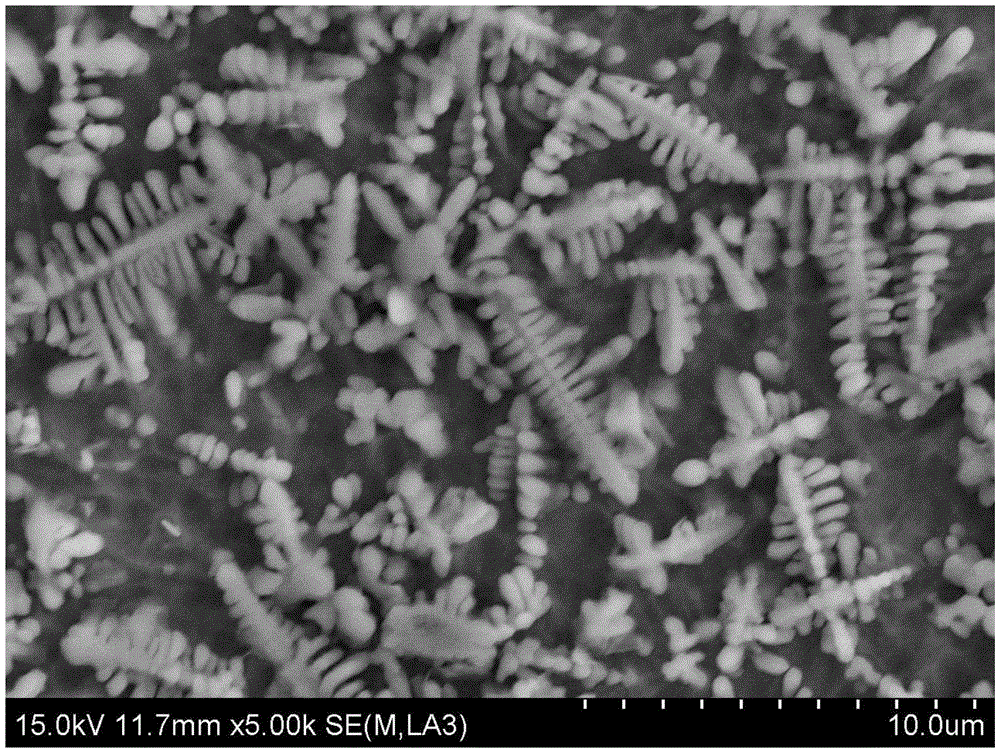

The invention discloses a method for manufacturing a high-performance in-situ TiC reinforced titanium-based composite workpiece on the basis of CNTs and a laser additive manufacturing and processing technology. The method includes the following steps that (1) the carbon nano tubes are subjected to preliminary ultrasonic dispersion treatment; (2) pure titanium powder with the average particle size of 45-75 microns is mixed with the carbon nano tubes to obtain a mixture, and CNTs / Ti mixed powder is obtained by ball-milling the mixture through a ball mill under the protection of argon; and (3) the ball-milled CNTs / Ti mixed powder is shaped through a laser additive manufacturing and processing method so as to obtain a high-performance in-situ TiC reinforced titanium-based composite body. The method has the advantages that in-situ TiC reinforcement phases are formed on the basis of a CNTs in-situ reaction and evenly distributed in a titanium substrate, and the interface bonding strength is high; grains of a composite are refined remarkably; net forming or near-net forming of a test piece can be achieved; any complex heterogeneous part can be formed.

Owner:南京瑞德增域三维技术发展有限公司

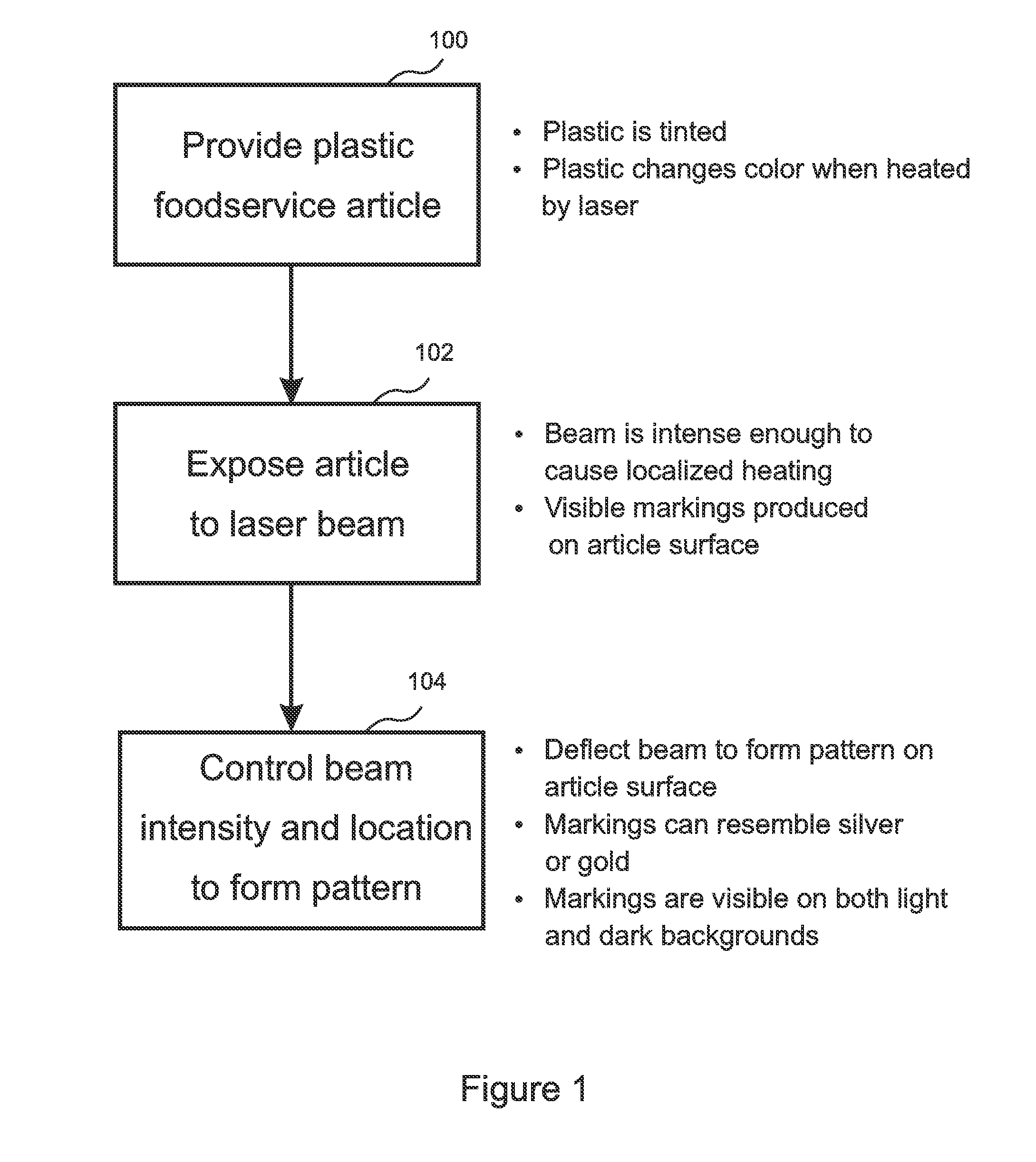

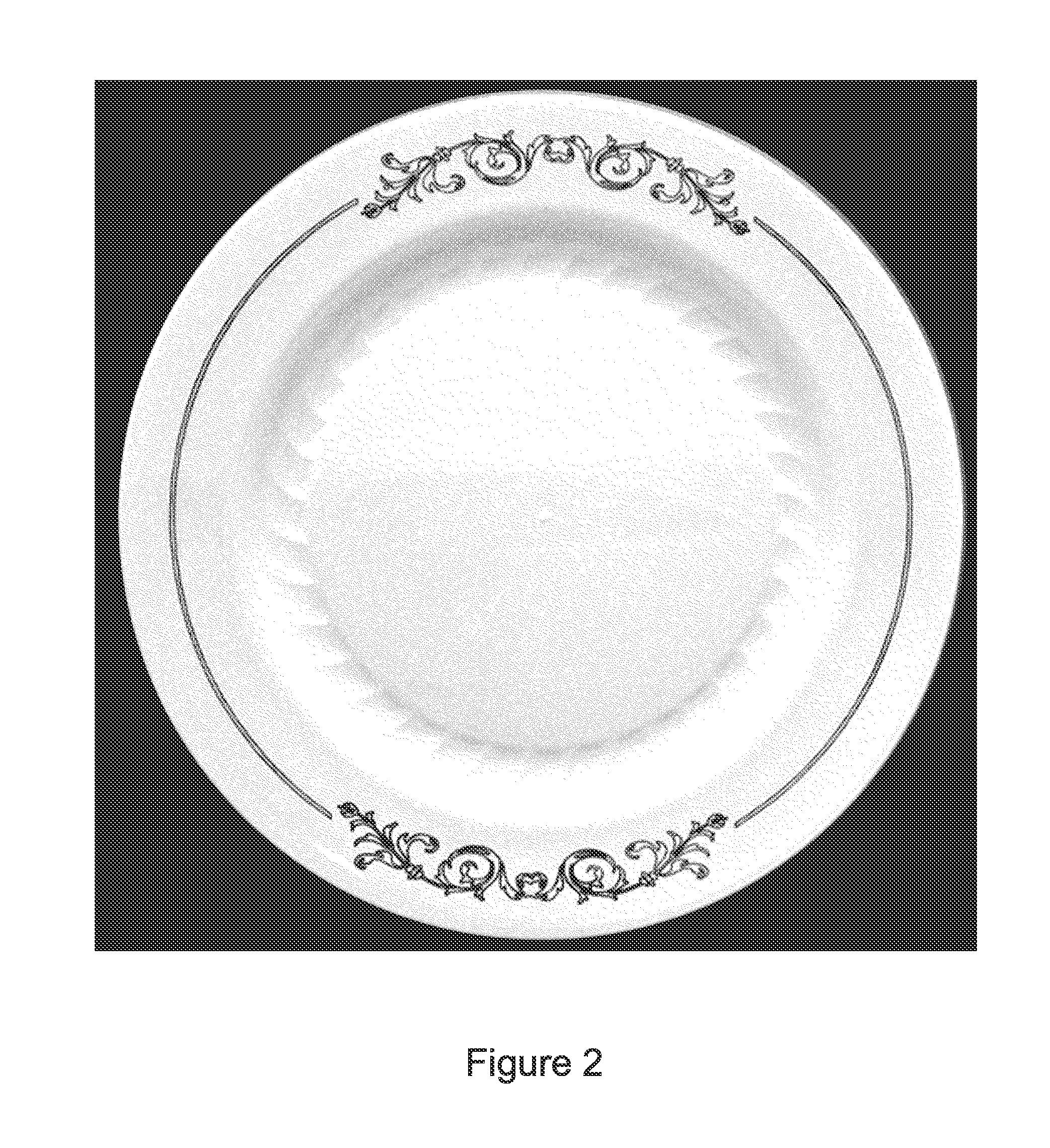

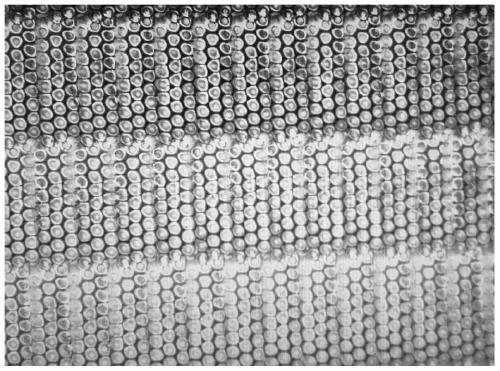

Food service articles bearing decorative markings, images, and/or custom content and method therefor

InactiveUS20130140746A1Increase contrastRemoving key impedimentDecorative surface effectsDuplicating/marking methodsPersonalizationPolystyrene

A plastic food service article bearing a decorative mark or image and method therefor is disclosed. The method includes providing an article made from a colored plastic such as polystyrene, polypropylene, polyethylene, PET, PLA, ABS, etc., that discolors when irradiated with a laser beam; applying a laser beam to cause localized surface discoloration; and controlling the deflection and amplitude of the beam to form a surface decoration and / or image. In embodiments, the laser is a YAG or Fiber laser, the markings emulate silver or gold or pewter without applying metals, inks, or coatings to the plastic articles. The markings are clearly visible against both light and dark backgrounds, and can be placed in food-contact areas of the articles. The technique can be used for marking customized and personalized designs, images, and photographs on food service articles. Embodiments can be used to decorate plates and / or cutlery.

Owner:WADDINGTON NORTH AMERICA

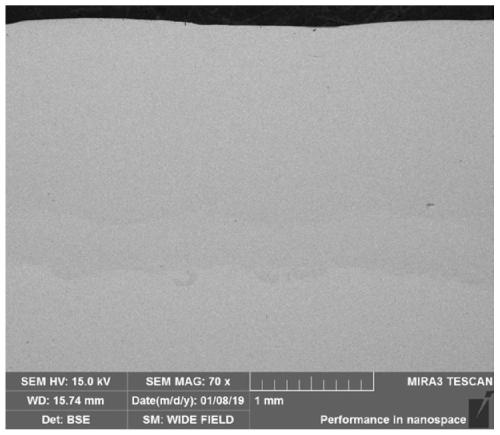

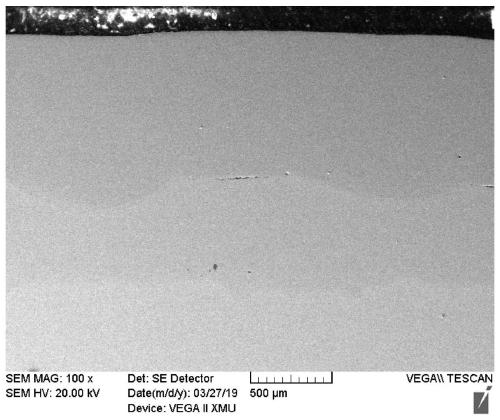

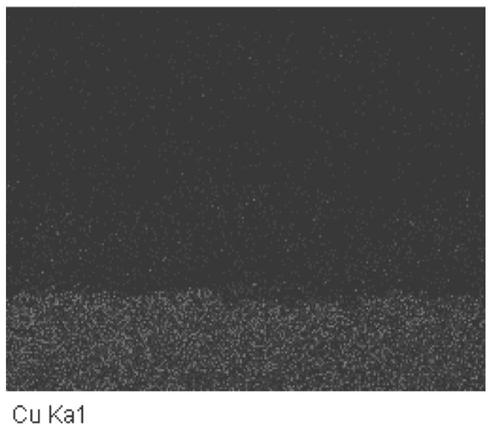

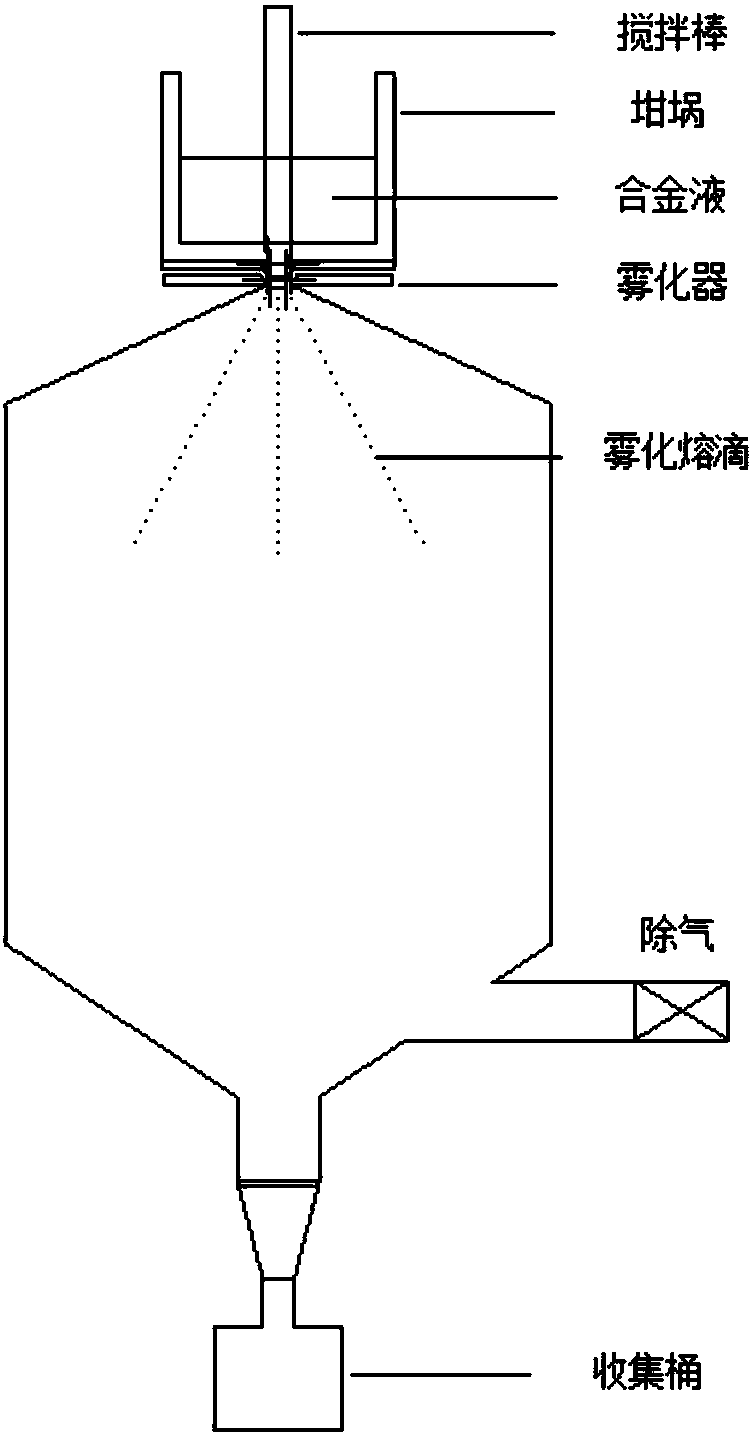

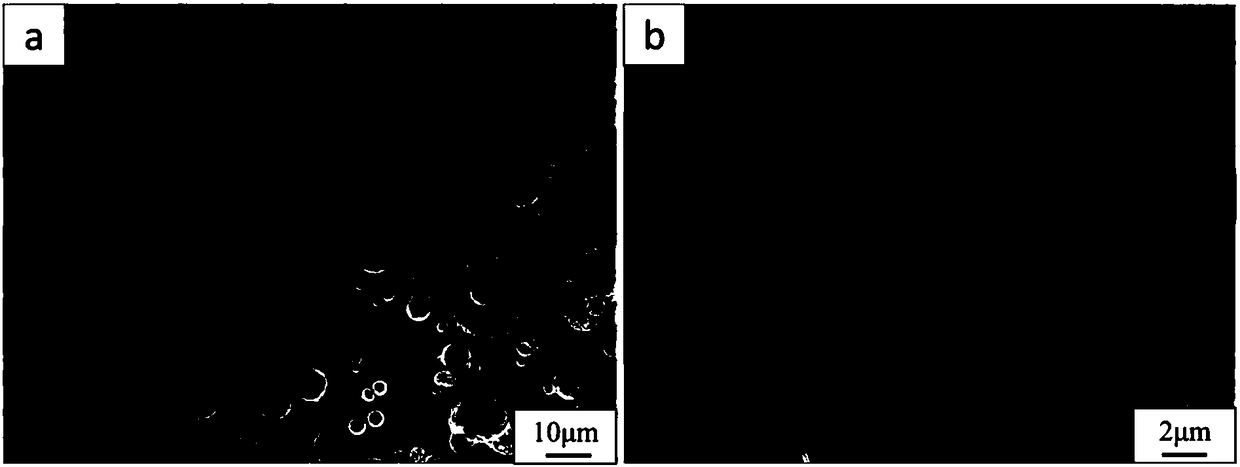

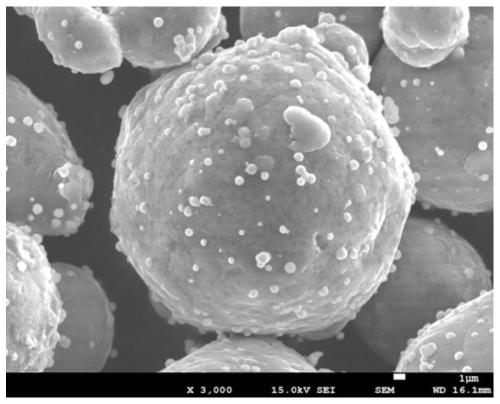

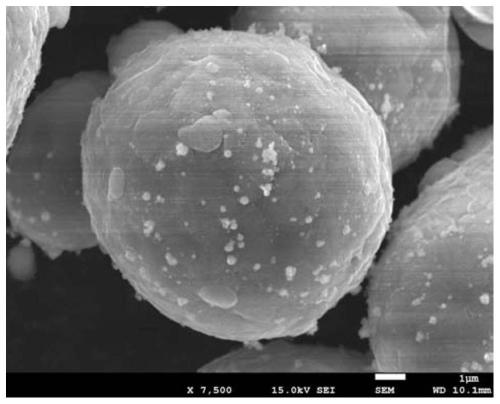

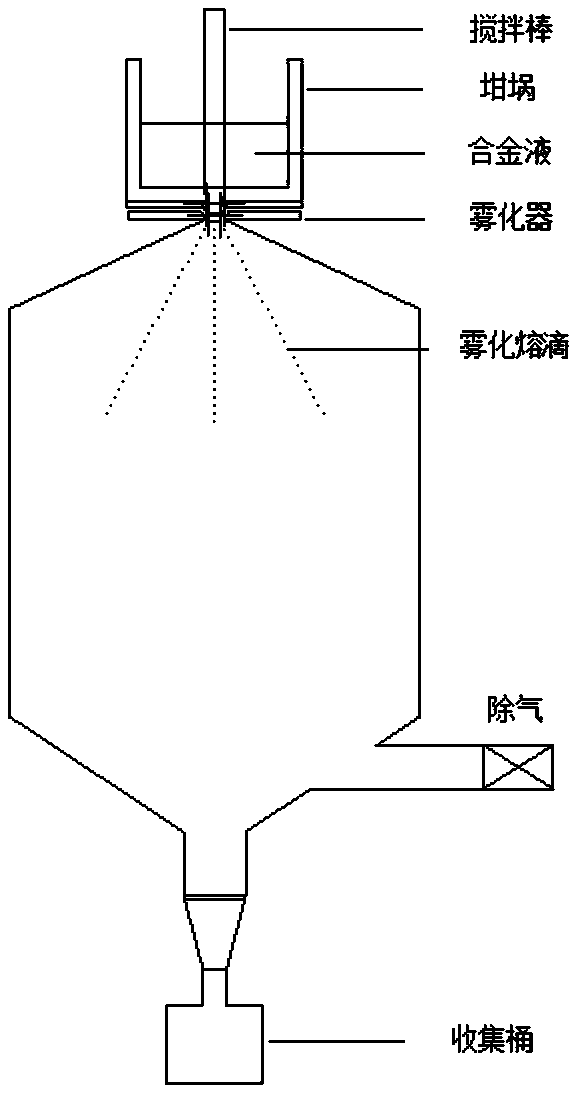

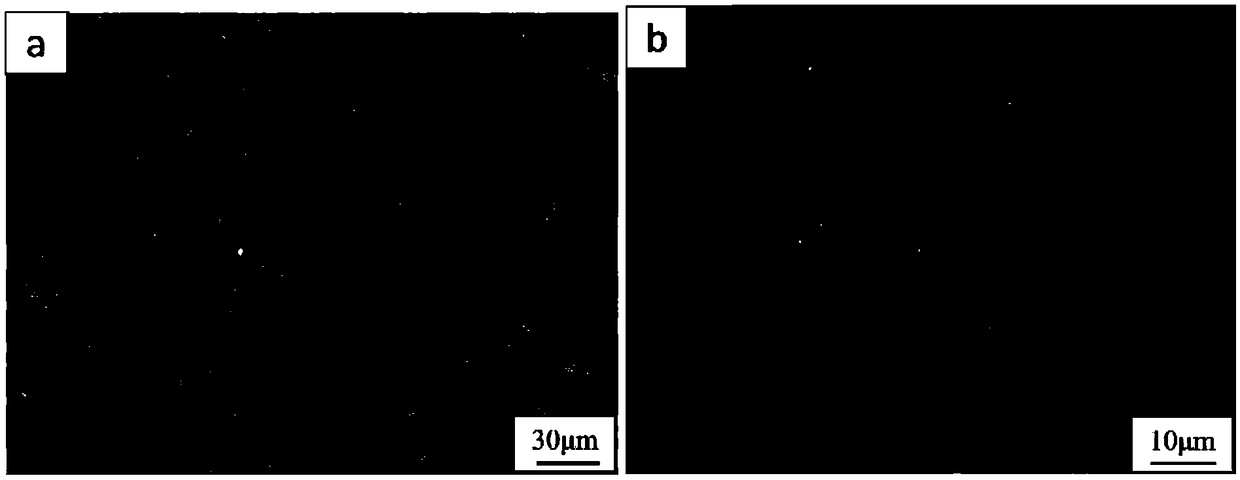

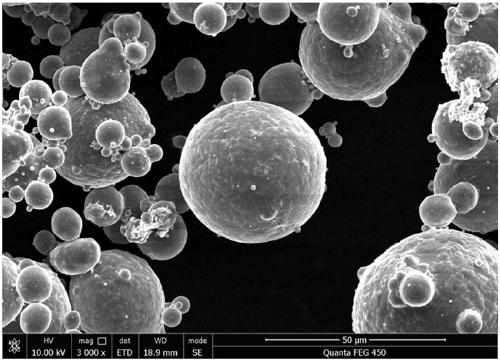

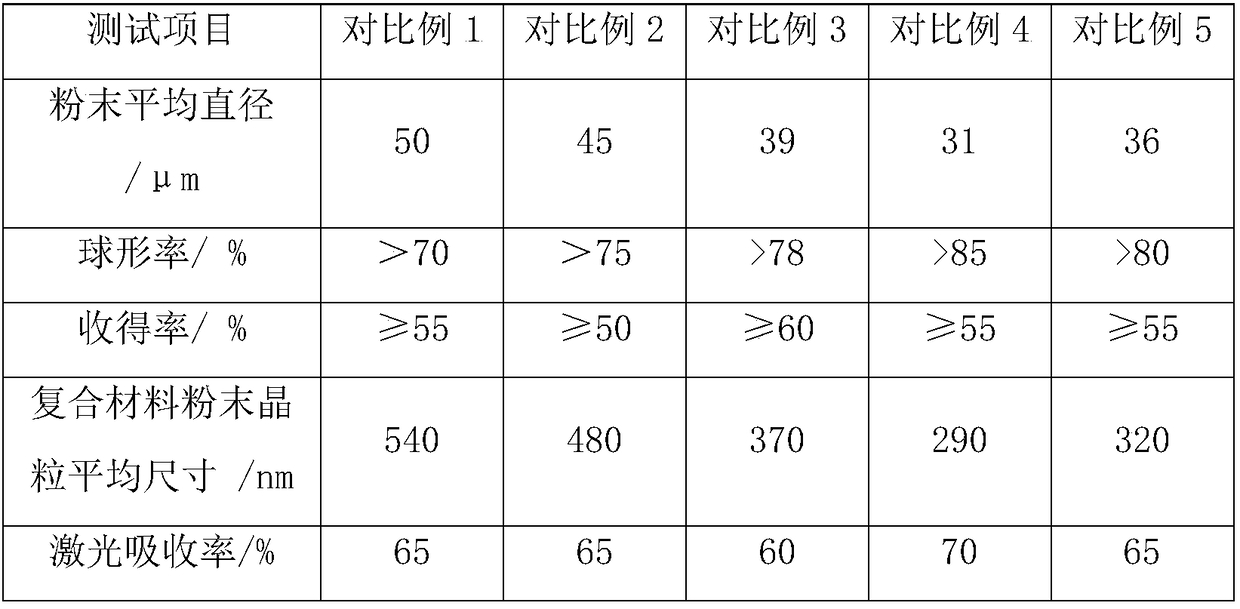

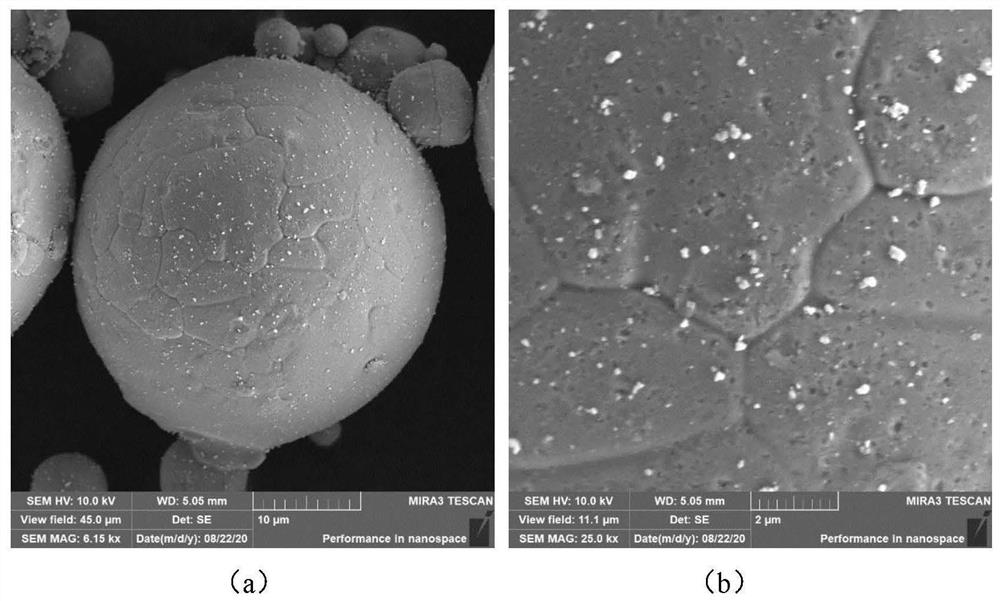

Aluminum-based composite material powder for laser reinforcement manufacturing and preparation method thereof

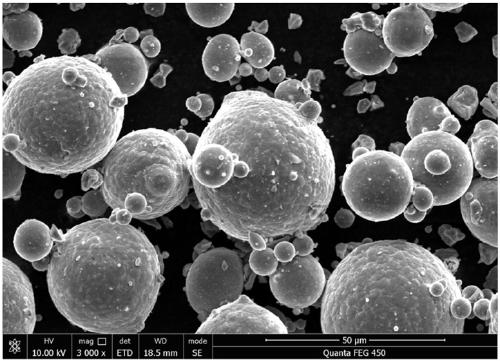

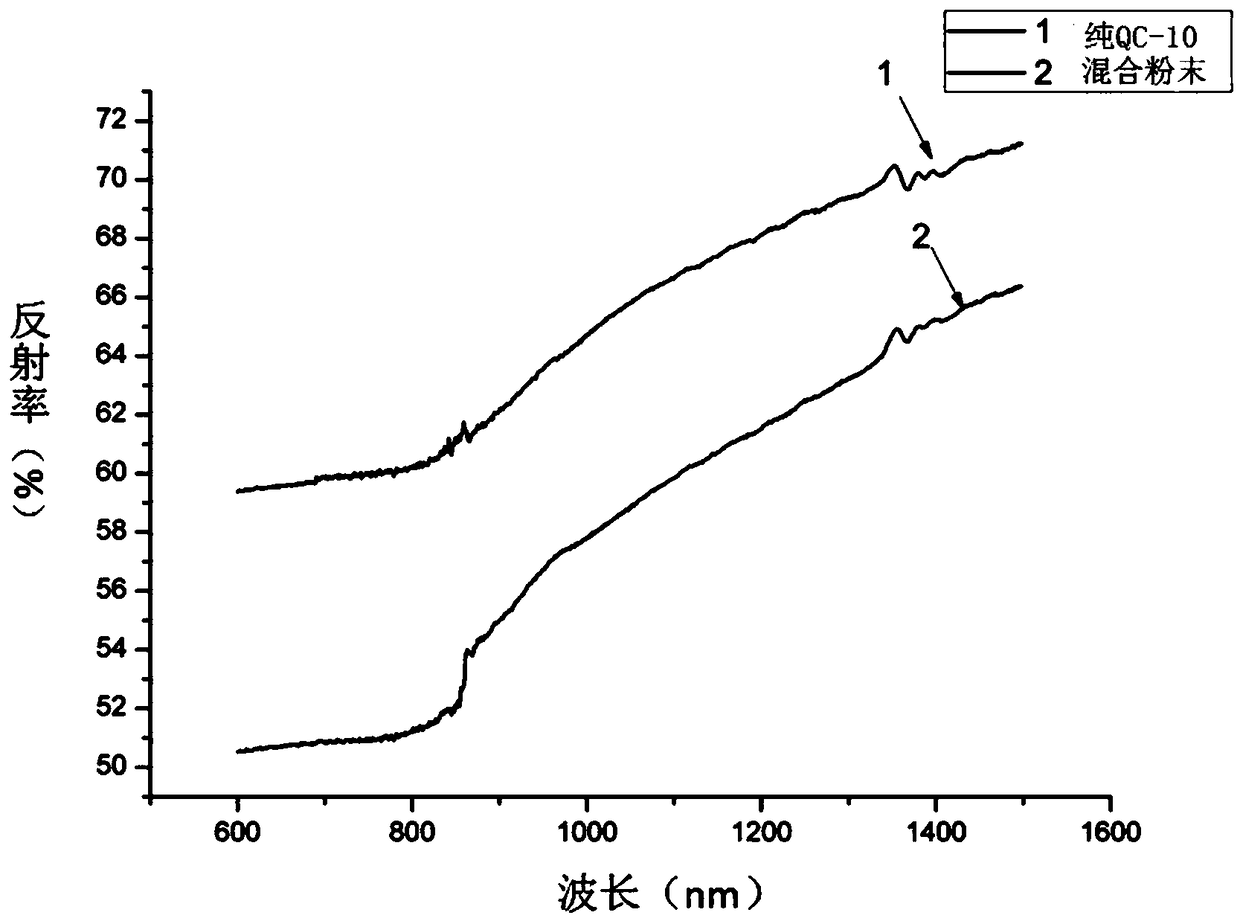

InactiveCN108372292AImprove laser absorption rateHigh strengthAdditive manufacturing apparatusAluminum matrix compositesGrain structure

The invention provides a preparation method of aluminum-based composite material powder for laser reinforcement manufacturing. The preparation method comprises the following steps that pure aluminum,Al-Zr intermediate alloy, Al-Sc intermediate alloy, Al-Mn intermediate alloy, Al-Ti intermediate alloy, industrial pure Mg, KBF4 and K2TiF6 are used as raw materials. In-situ TiB2 micro-nanoparticle reinforced Al-Mg composite materials are prepared by in-situ melt self-control method, and TiB2 particle reinforced aluminum-based composite material powders are prepared by high temperature gas atomization. The median particle size of the powder particles is controllable in the range of 3-180[mu]m, the spherical rate is more than 90%, the powder yield is more than or equal to 60%, and the laser absorption rate is more than or equal to 45%. Nano-sized TiB2 particles are uniformly dispersed in the aluminum alloy matrix, and the grain structure of the composite material is uniform and fine equiaxed grains. The aluminum-based composite material powder has good laser absorptivity, is suitable for laser reinforcement manufacturing technology and can exhibit good mechanical properties when used in laser reinforcement manufacturing.

Owner:SHANGHAI JIAO TONG UNIV

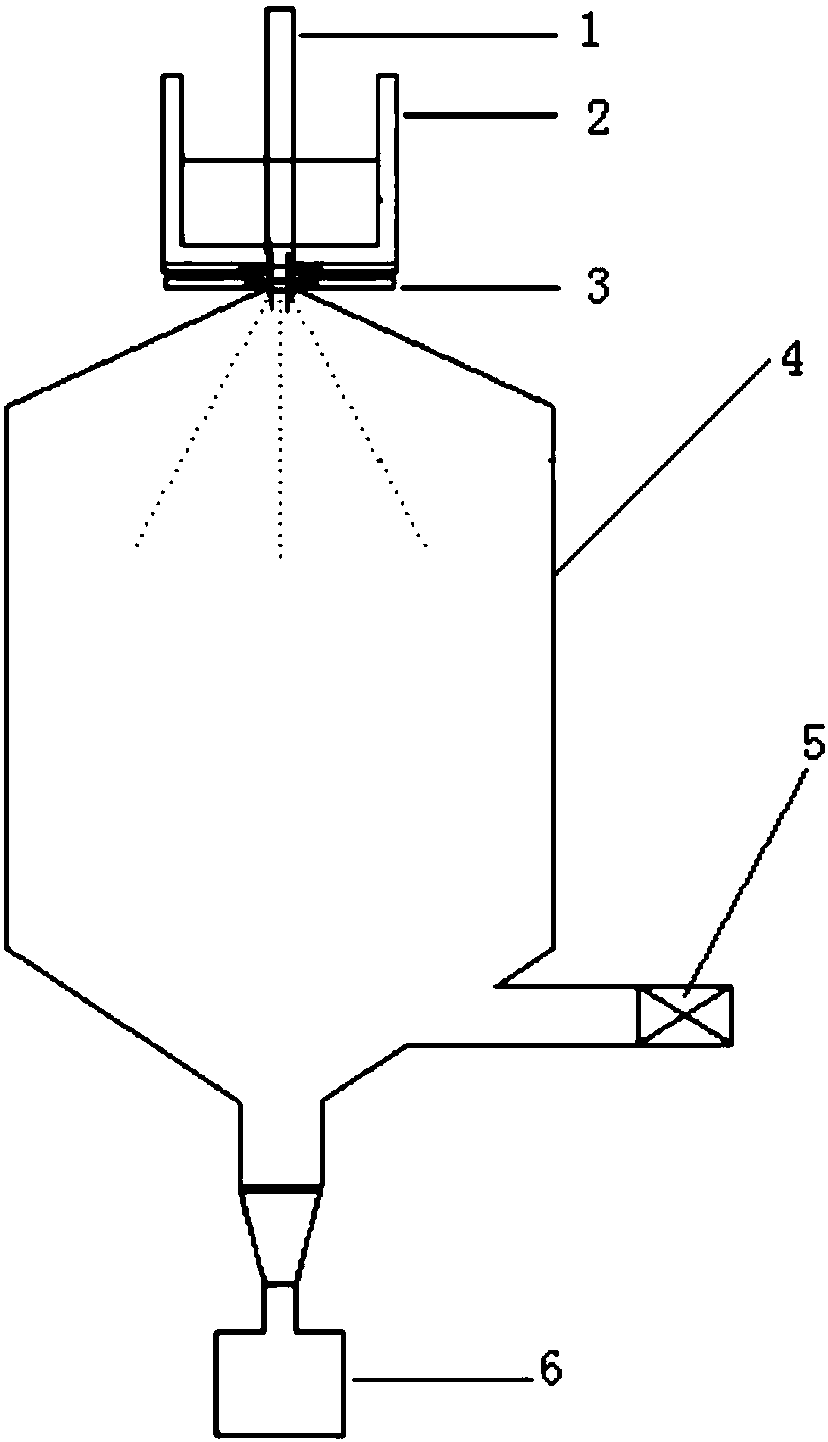

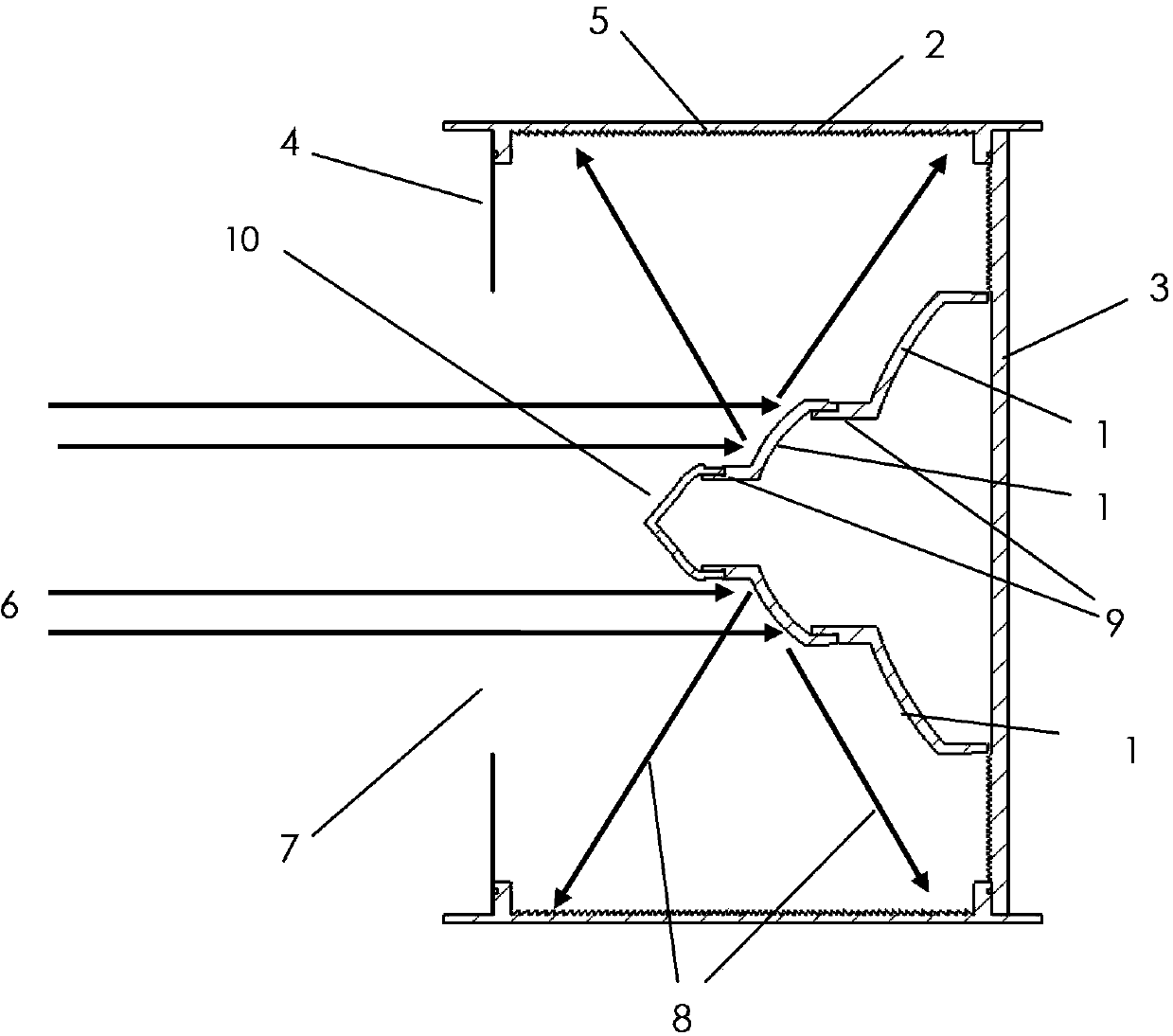

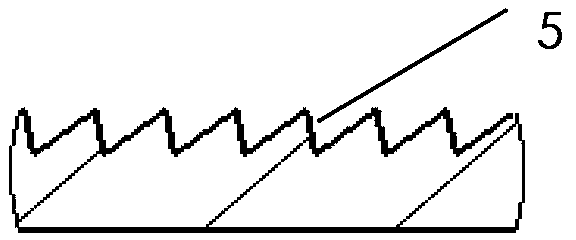

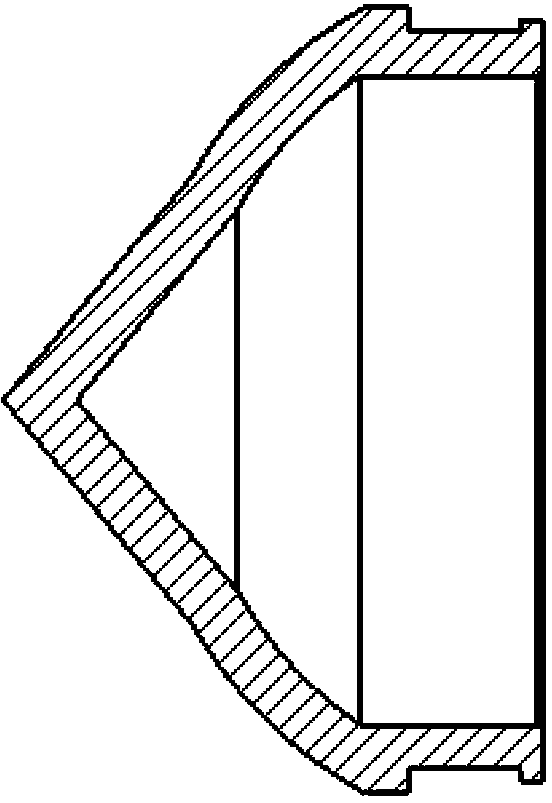

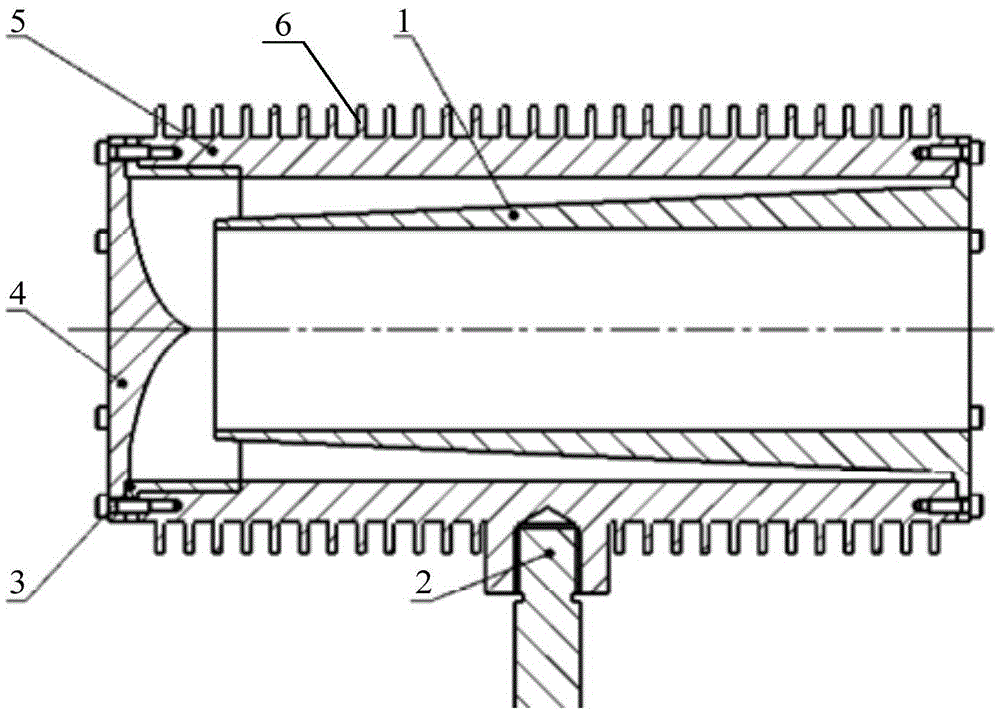

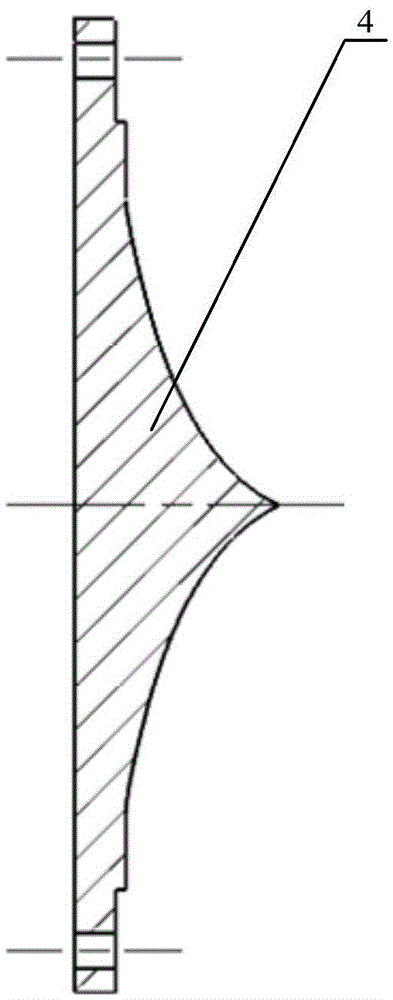

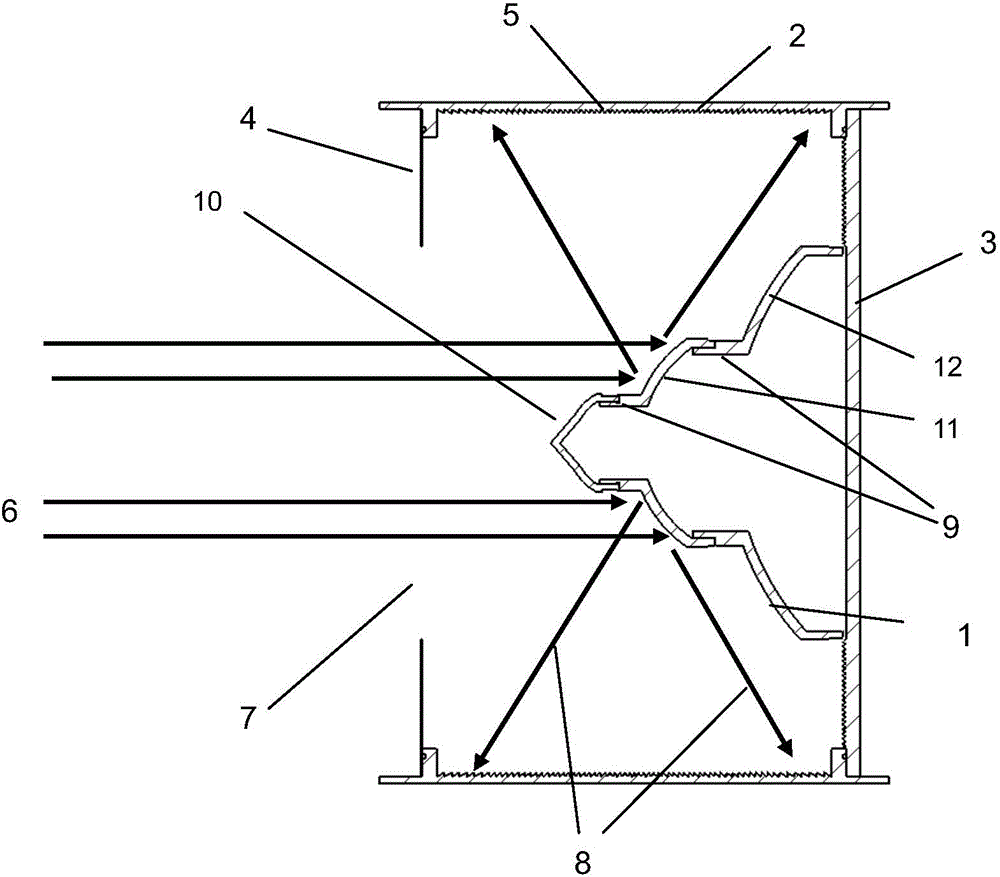

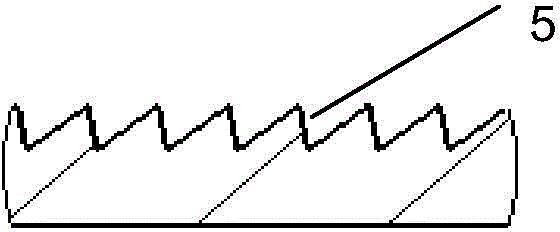

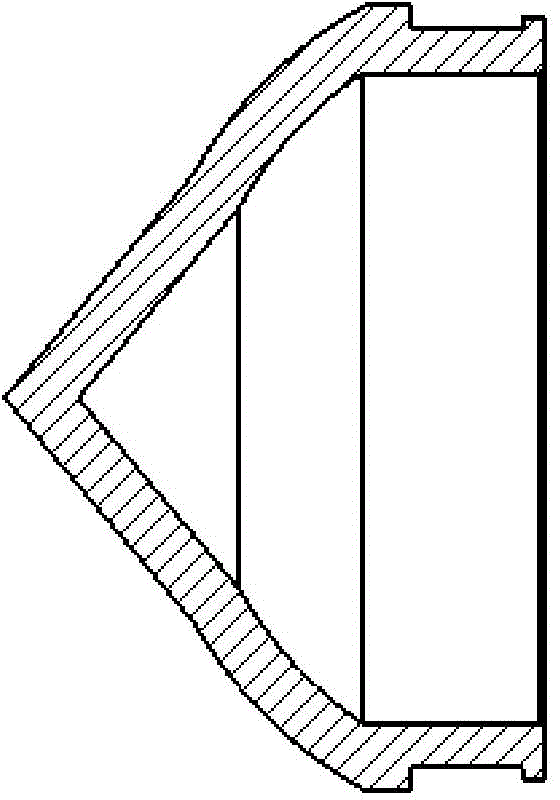

High-energy laser beam expanding and absorbing device

InactiveCN103389157AHigh measurement accuracyAchieve absorptionPhotometry using electric radiation detectorsHigh power lasersLaser power density

The invention discloses a high-energy laser beam expanding and absorbing device which comprises a laser beam expanding cone, an energy absorption cavity, a front panel and a fixing plate, wherein the energy absorption cavity adopts a hollow cylinder; the front panel is arranged at a laser incident end of the energy absorption cavity, and the fixing plate is arranged at the rear end of the energy absorption cavity and used for fixing the laser beam expanding cone; and the laser beam expanding cone comprises a pointed beam expanding cone, at least two spherical beam expanding cones and cylinder transition sections which are arranged in the laser incident direction sequentially, and radii of cylinders of the cylinder transition sections are increased gradually in the laser incident direction. The laser beam expanding cone simultaneously realizes beam expanding of incident laser beams in the length direction and the circumference direction of the absorption cavity, and effectively reduces the power density of laser shot to a heat absorption cylinder by the laser beam expanding cone; and by means of the high-energy laser beam expanding and absorbing device, absorption and conduction of hundred thousand joules to a megajoule of high-power laser energy of continuous waves are realized, the measuring accuracy of an energy meter is improved greatly, and the device has wide applicability.

Owner:NORTHWEST INST OF NUCLEAR TECH

Metal-based material for preparation of crystallizer or tuyere as well as preparation method of metal-based material

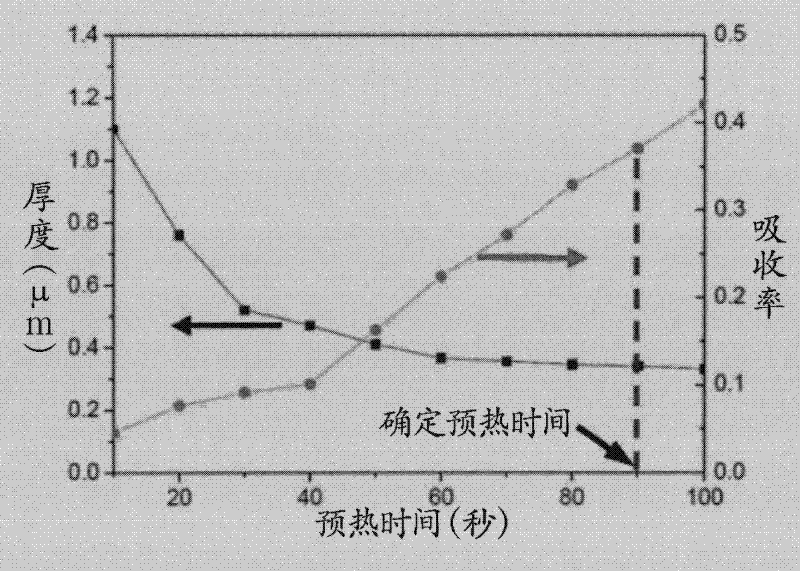

ActiveCN110144582AImprove high temperature wear resistanceLower perfect fitMetallic material coating processesSurface engineeringAlloy

The invention discloses a metal-based material for the preparation of a crystallizer or a tuyere and belongs to the technical field of surface engineering. According to the metal-based material, a transition layer is innovatively arranged between a Cu or Cu alloy matrix and a high-abrasion-resistance working layer by the adoption of a metallurgical bonding method, and made of at least one of pureCo metal, pure Ni metal, pure Cr metal, pure Cu metal, pure Mo metal, pure Ag metal and a NiCr or MCrAlY alloy; through the transition layer, the functions of improving the laser absorption rate, lowering the matrix heat conductivity, and lowering the dilution rate can be achieved; due to the existence of the transition layer, the thickness of the working layer can be adjusted within a range of 0.01-3 mm and the formation of surface cracks can be avoided; furthermore, the ratio of the thickness of the transition layer to that of the high-abrasion-resistance working layer is 1:(1-3), so that the perfect bonding of the transition layer and the high-abrasion-resistance working layer can be guaranteed within the ratio range; the formation of a high-abrasion-resistance coating or coating product which is free of surface cracks and subjected to metallurgical bonding on the Cu or Cu alloy matrix can be improved; the reliability of the crystallizer or the tuyere can be improved; and the service life of the crystallizer or the tuyere can be prolonged.

Owner:XI AN JIAOTONG UNIV

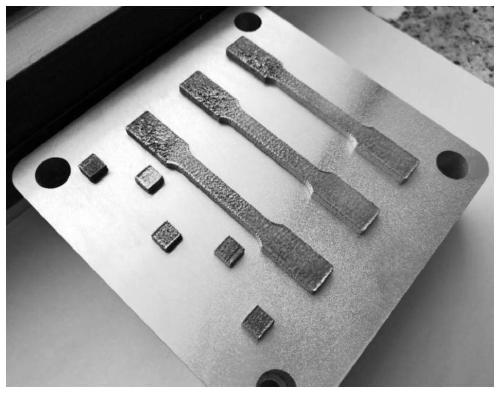

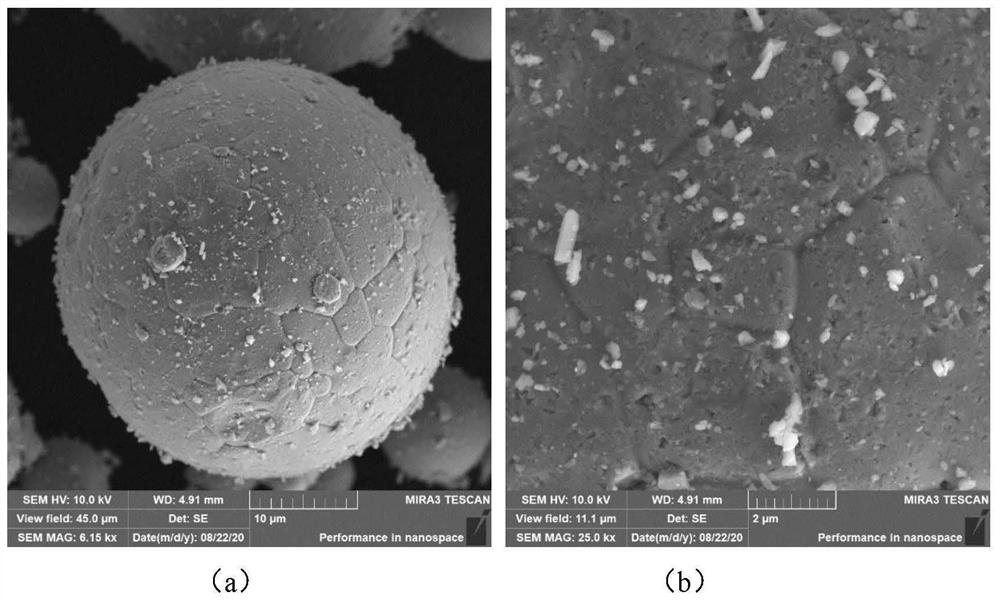

7XXX series in-situ aluminum-based composite material powder for laser additive manufacturing and preparation

InactiveCN108315577ASignificant progressHigh strengthAdditive manufacturing apparatusAbsorption rateLaser additive manufacturing

The invention provides a preparation method of 7XXX series in-situ aluminum-based composite material powder for laser additive manufacturing. The preparation method comprises the following steps: heating commercially pure aluminum; after covering with a high-temperature covering agent, raising the temperature and smelting; uniformly mixing KBF4 and K2TiF6; after drying, adding a mixture into a melt; after reacting, sequentially adding a needed intermediate alloy, commercially pure Mg and commercially pure Zn; adding a refining agent into the melt and carrying out degassing and refining; then carrying out gas atomization to obtain the 7XXX series in-situ aluminum-based composite material powder. According to the method provided by the invention, an in-situ TiB2 micron-nano-sized particle enhanced 7XXX series composite material is prepared by adopting an in-situ melt automatic generation and high-temperature gas atomization method; TiB2 particle enhanced aluminum-based composite materialpowder is prepared; TiB2 particles are uniformly dispersed in an aluminum matrix. The aluminum-based composite material powder prepared by the method has a good laser absorption rate and is suitablefor a laser additive manufacturing technology.

Owner:SHANGHAI JIAO TONG UNIV

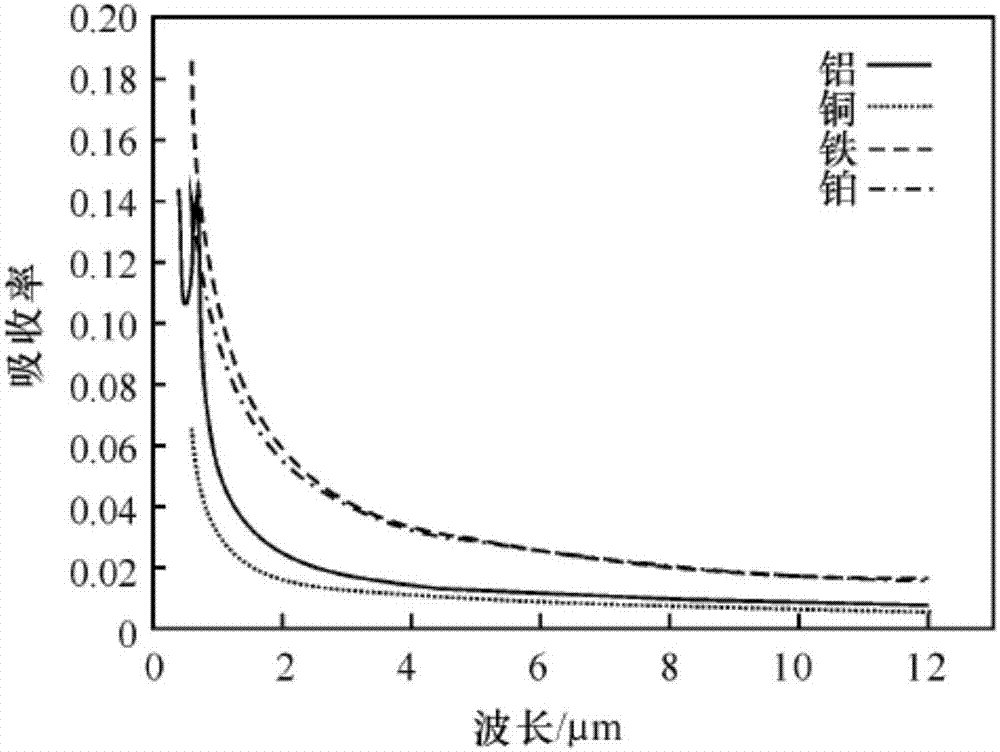

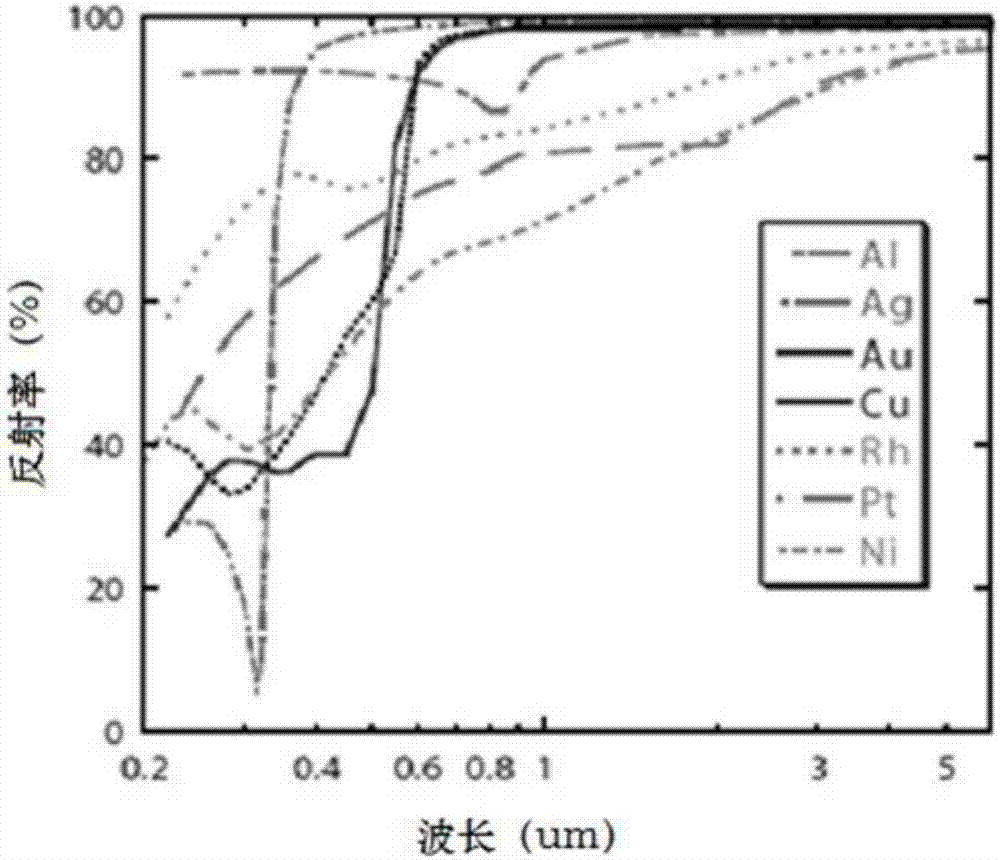

Surface modified metal powder with high laser reflectivity and 3D printing method

InactiveCN109746435AGood printing performanceSimple processAdditive manufacturing apparatusTransportation and packagingCobaltMechanical property

The invention belongs to the field of metal material preparation, and relates to surface modified metal powder with high laser reflectivity and the application of the surface modified metal powder in3D printing. According to the surface modified metal powder with high laser reflectivity and the application of the surface modified metal powder in 3D printing, nickel, cobalt or iron metal particleswith high laser absorptivity wrap the surface of aluminum, copper and aluminum alloy or copper alloy powder with high laser reflectivity by means of electroless plating, namely, the powder with highlaser reflectivity is modified into the powder with high laser absorptivity, so that the printing performance of the metal powder with high laser reflectivity in the 3D printing process is enhanced, and the 3D printing of the metal powder with high laser reflectivity can be realized. Compared with that of conventional commercial aluminum, copper and aluminum alloy or copper alloy powder used for 3D printing, the laser absorptivity and printing performance are improved after surface modification wrapping, the sphericity of the powder does not change a lot, the powder spreading process is not affected, and printed metal parts are compact and have good mechanical properties.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

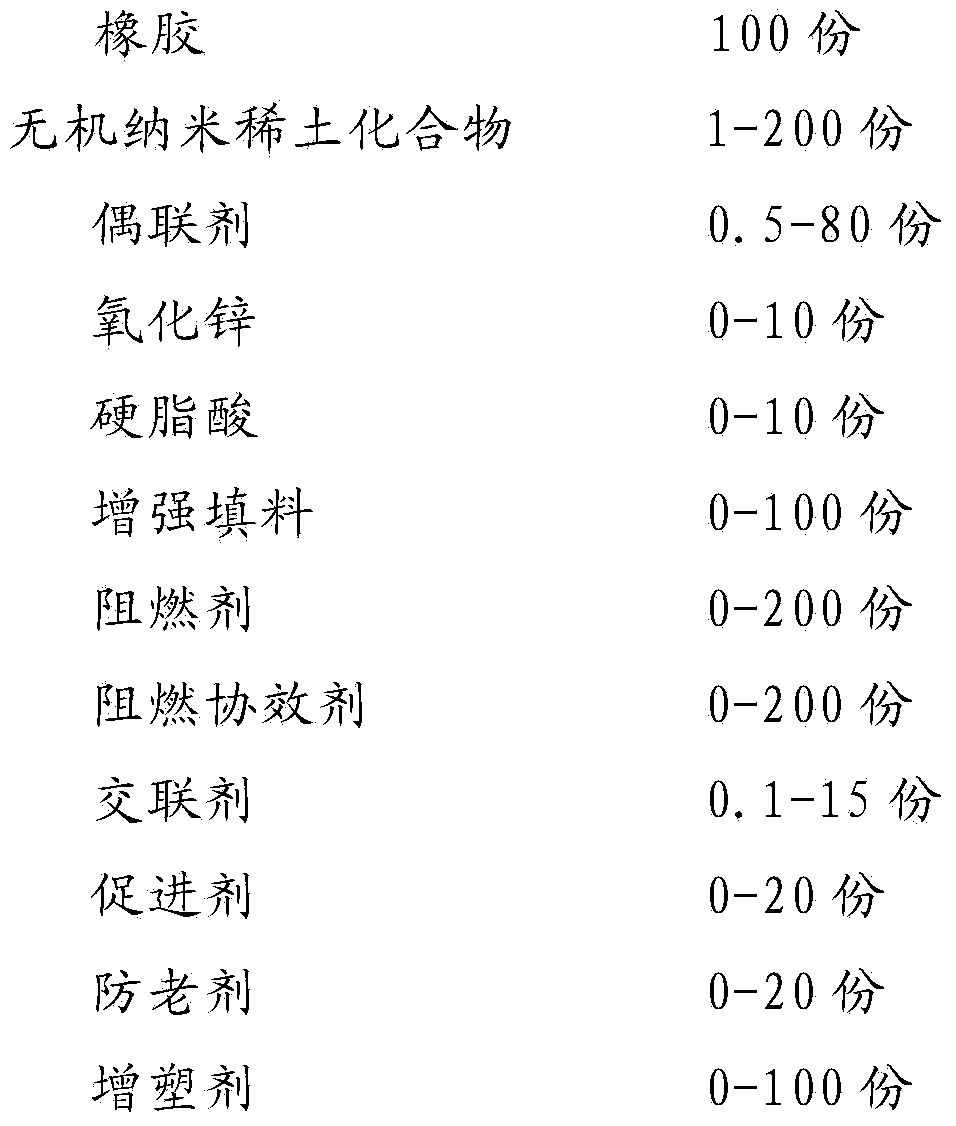

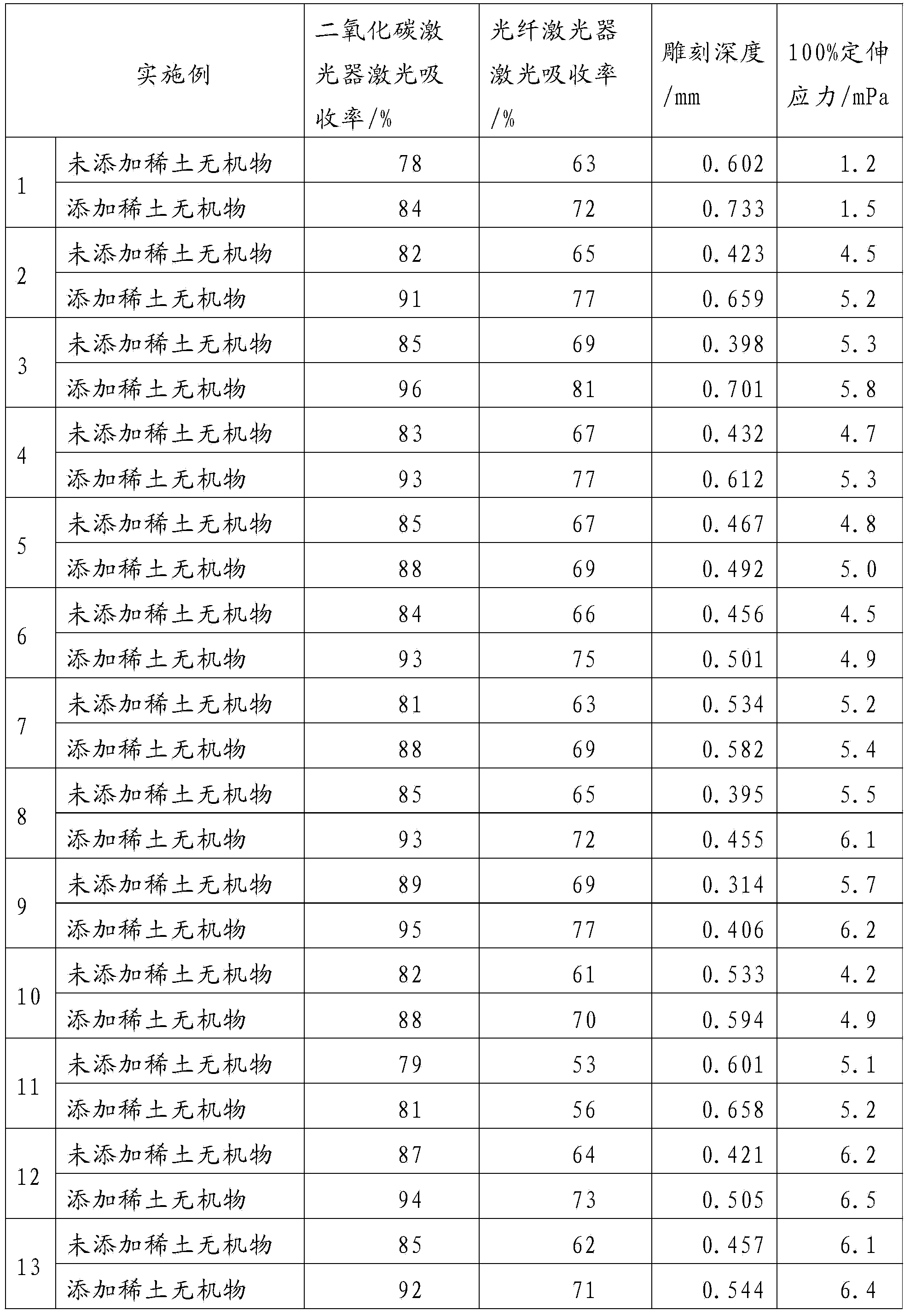

Rare-earth/rubber composite material easily subjected to laser engraving

The invention relates to a rare-earth / rubber composite material easily subjected to laser engraving. The rare-earth / rubber composite material easily subjected to laser engraving, provided by the invention, has the advantages that the quality of laser engraving can be guaranteed, the speed of engraving can be increased, the cost is reduced, and the absorption rate of laser is increased. The composite material is mainly prepared from the following ingredients in parts by weight: 100 parts of rubber, 1-200 parts of inorganic nano rare-earth compound, 0.5-80 parts of coupling agent, 0-10 parts of zinc oxide, 0-10 parts of stearic acid, 0-100 parts of reinforcing filler, 0-200 parts of flame retardant, 0-200 parts of flame-retardant synergist, 0.1-15 parts of cross-linking agent, 0-20 parts of accelerant, 0-20 parts of anti-aging agent and 0-100 parts of plasticizer, wherein the inorganic nano rare-earth compound is one or a randomly-proportioned mixture of more than two of nano rare-earth oxide, nano rare-earth chloride, nano rare-earth sulfide, nano rare-earth carbonate, nano rare-earth nitrate, nano rare-earth sulfate and nano rare-earth hydroxide, and rare-earth elements are selected from scandium, yttrium, lanthanum, cerium, praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium.

Owner:中国印刷科学技术研究院有限公司

Laser welding method

InactiveCN104439587AImprove laser absorption rateHigh temperature toleranceSoldering apparatusLaser beam welding apparatusControl equipmentLaser

The invention provides a laser welding method. According to the method, a laser welding machine and a circuit board to be welded are provided, a plurality of bonding pads to be welded are arranged on the circuit board, the laser welding machine comprises a focusing head and a tin feeding head, the tin feeding head comprises a tin feeding end, the tin feeding end can feed a tin wire continuously, the tin feeding head is located between the focusing head and the bonding pads, before high-power light of the focusing head exits or while high-power light exits, a section of the tin wire is fed by the tin feeding head, and the tin wire, the focusing head and the bonding pads are located on the same straight line. According to the laser welding method, the welding speed is high, the welding precision is high, the requirement for control equipment is not high, the production cost is low, stability is improved greatly, and the laser welding method has high market value.

Owner:深圳云麟科技有限公司

Preparation method for in-situ aluminum-based composite material

InactiveCN108660332AHigh material strengthImprove laser absorption rateAluminum matrix compositesMg composite

The invention discloses a preparation method for an in-situ aluminum-based composite material. The preparation method comprises the following steps of: adding a high-temperature covering agent into pure aluminum to smelt, thereby obtaining melt; adding KBF4 and KTiF6 into the melt, and uniformly mixing to react; removing a byproduct, and sequentially adding an aluminum-copper intermediate alloy, an aluminum-zirconium intermediate alloy, an aluminum-scandium intermediate alloy, an aluminum-manganese intermediate alloy, an aluminum-titanium intermediate alloy and pure magnesium, adding a harmless aluminum alloy refining agent, and performing degassing refining and gas-atomizing at a temperature being 700-850 DEG C, thereby obtaining in-situ self-generated TiB2 particle reinforced Al-Cu-Mg composite material powder. The preparation method prepares the aluminum-based composite material which is high in laser absorbing rate and is high in particle spheroidization rate; and moreover, the preparation method is simple in operation, is simple and liable to implement, is low in cost, is high in efficiency and is suitable for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

Aluminum alloy composite material for 3D printing, 3D printing product and preparation method thereof

InactiveCN109266916AGood printing performanceGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencyVolumetric Mass DensityAlloy composite

The invention discloses an aluminum alloy composite material for 3D printing, a 3D printing product and a preparation method thereof. The aluminum alloy composite material for the 3D printing is capable of introducing TiB2 and Si into an aluminum alloy, apparently improving laser absorptivity, and reducing a melting point. The obtained composite material has certain mobility, and a good printing property, can be applied for the laser 3D printing, is better in melting formability of a laser selective area, and high in density of a formed part, and has good performance.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

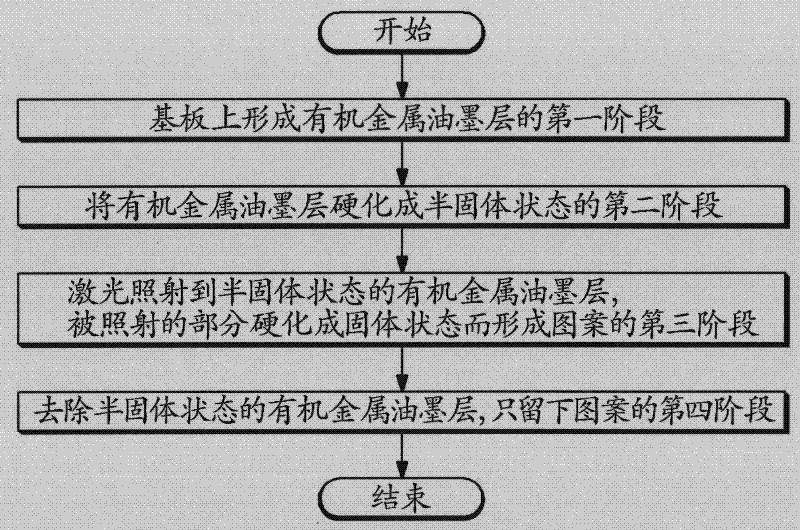

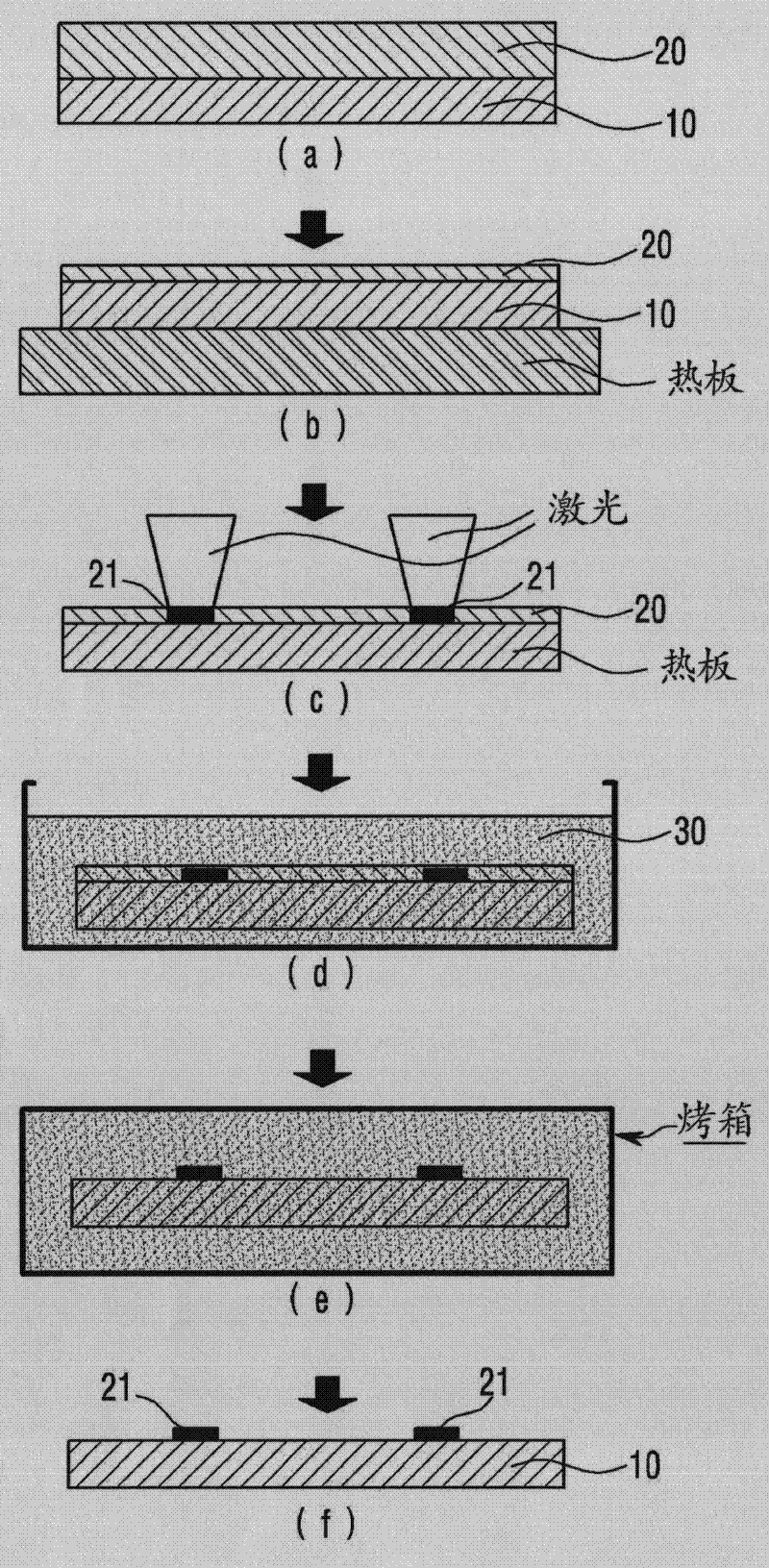

Method of fabricating pattern

InactiveCN102338983AEasy to manufactureImprove light absorptionPrinted circuit aspectsPhotomechanical apparatusSemi solidEngineering

Owner:KOREA ADVANCED INST OF SCI & TECH

Aluminum-lithium-matrix composite material powder as well as preparation method and application thereof

ActiveCN108998699AImprove mechanical propertiesImprove laser absorption rateAdditive manufacturing apparatusTransportation and packagingLithiumAbsorption rate

The invention provides an aluminum-lithium-matrix composite material powder as well as a preparation method and an application thereof. The aluminum-lithium-matrix composite material powder comprisesa matrix alloy and reinforced phases distributed into the matrix alloy, wherein the matrix alloy comprises 2.5%-3.5% of Li, 1%-2% of Cu, 0.1%-0.2% of Zr, 0.4%-0.5% of Mg, 0.15%-0.2% of Sc, 0.1%-0.2% of Cd and the balance Al; and the reinforced phases are TiB2 particles. The preparation method comprises the following steps: taking pure aluminum, pure Li or Al-Li intermediate alloy, Al-Cu intermediate alloy, Al-Zr intermediate alloy, Al-Sc intermediate alloy, Al-Mg intermediate alloy, Al-Cd intermediate alloy and TiB2 / Al base metal as raw materials, and preparing an intermediate melt; carrying out gas atomization on the intermediate melt to prepare a composite material powder; and finally carrying out uniform heat treatment to obtain the aluminum-lithium-matrix composite material powder. Thealuminum-lithium alloy powder prepared by the preparation method is higher in laser absorption rate, and more applicable to a laser additive manufacturing technology.

Owner:SHANGHAI JIAO TONG UNIV

Repairing composite layer of amorphous/nanocrystalline cooling roller and preparation method of repairing composite layer

ActiveCN103895280AGood workmanshipInhibit sheddingElectrolytic coatingsMetallic material coating processesHigh power lasersHigh energy

The invention belongs to the technical field of material science, and particularly relates to a repairing composite layer of an amorphous / nanocrystalline cooling roller and a preparation method of the repairing composite layer. The composite layer consists of two layers, namely a copper-based alloy layer connected with base materials and a nickel-based alloy layer, wherein the copper-based alloy layer comprises the following components by weight percent: 7-9% of Ni, 8-12% of Sn, 5-15% of Co, 0.8-2% of Si and the balance being Cu; the nickel-based alloy layer comprises one of Ni-Co alloy, Ni-P alloy, Ni-Fe alloy and Ni-Cr alloy, and the weight content of Ni in alloy is 60-75%. The preparation method comprises the following steps of pretreating the surface of the cooling roller, electroplating the copper-based alloy layer and performing wide-strip cladding on the nickel-based alloy layer by a high-power laser. The prepared composite coating is uniform and compact, and excellent in wear resistance and heat resistance, and has the characteristics of high cladding efficiency and high energy absorptivity of the cooling roller to the laser beam.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

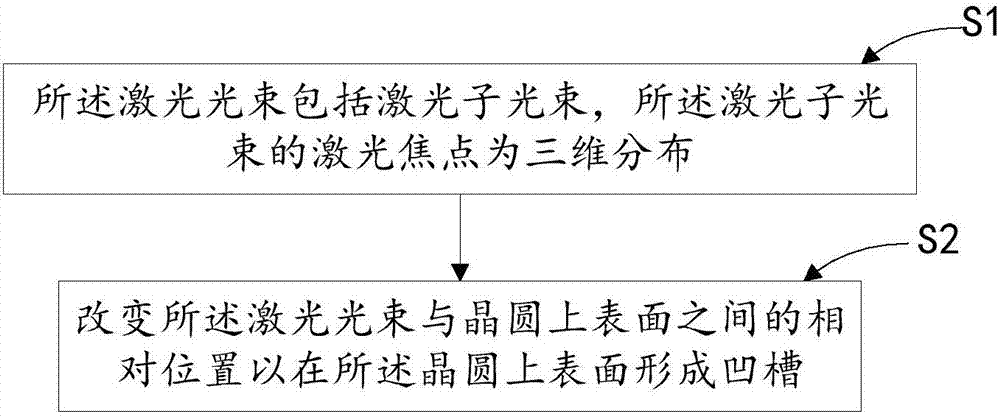

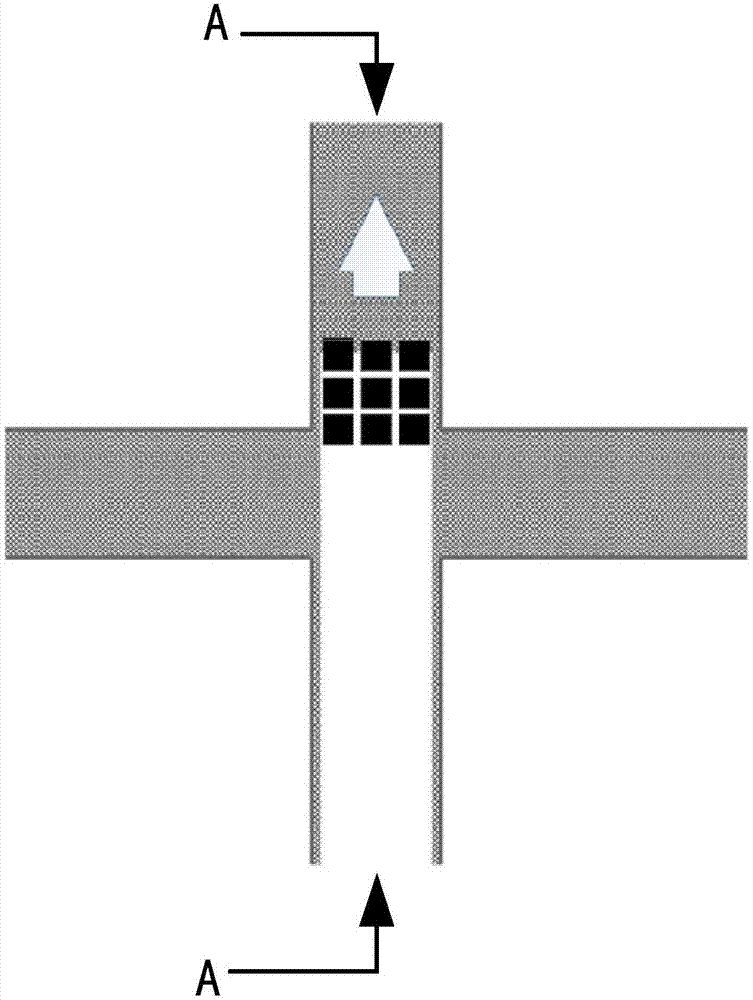

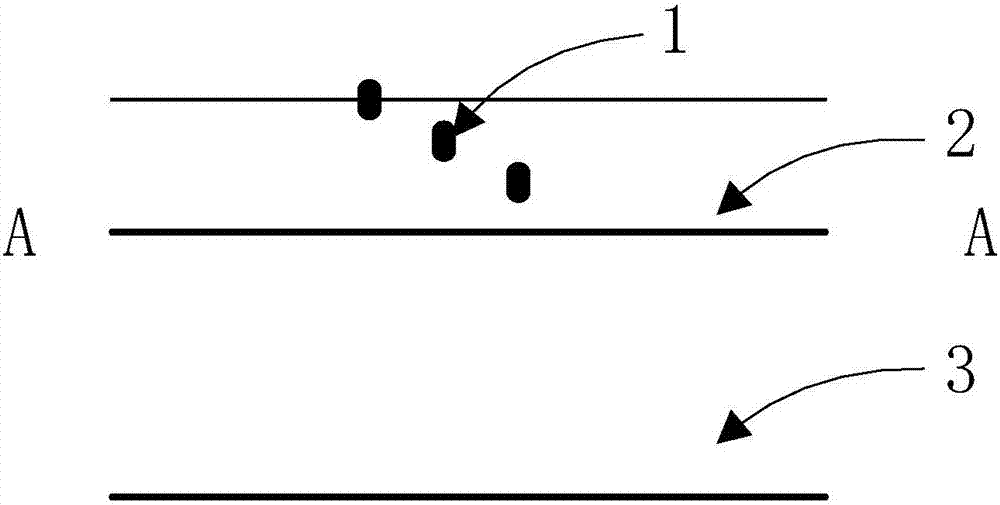

Method and device for machining wafer by using laser

ActiveCN107252982APromote absorptionImprove absorption rateLaser beam welding apparatusLaser processingLight beam

The invention provides a method and device for machining a wafer by using laser. According to the method, by changing the relative position between a laser beam and the upper surface of the wafer, a groove is formed in the upper surface of the wafer; and the laser beam comprises laser sub beams, and laser focuses of the laser sub beams are distributed three-dimensionally. By adopting the method and device for machining the wafer by using the laser, a three-dimensionally distributed light spot combination can be formed in the wafer by the laser focuses through treatment, three-dimensional-level machining on the upper surface of the wafer is achieved and a Low-K layer of the upper surface of the wafer is removed efficiently, and further the working efficiency and the precision of the machining method and the evenness of the separated wafer are enhanced.

Owner:北京中科镭特电子有限公司

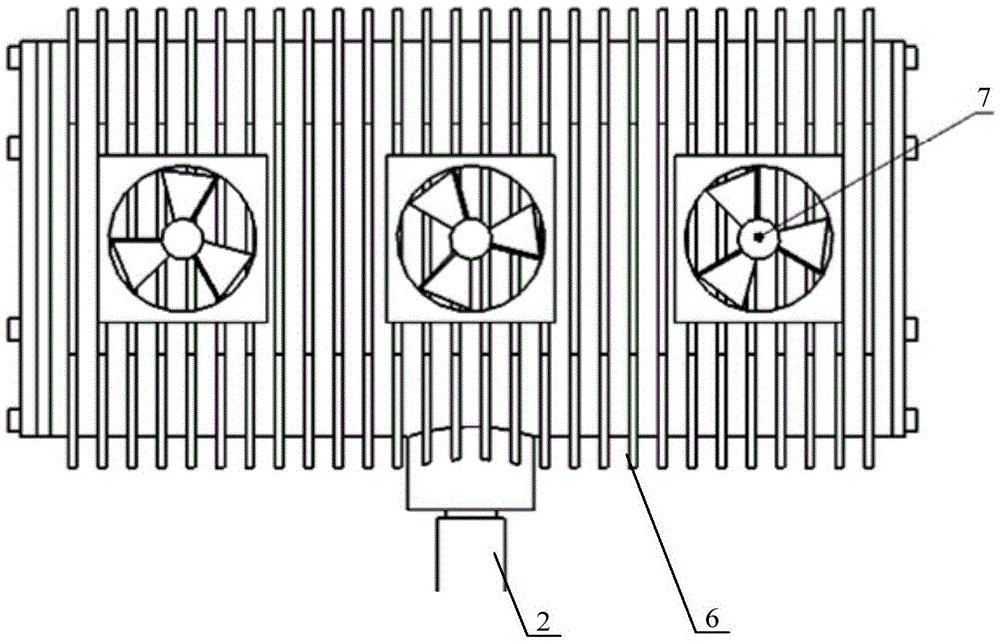

Laser beam-expanding absorption device

InactiveCN105428985AIncrease cooling areaNo deformationLaser detailsOptical elementsLaser technologyCooling effect

The invention discloses a laser beam-expanding absorption device, belongs to the technical field of lasers, and aims at solving the technical problems that a reflecting surface in a conical cavity is destroyed, the laser reflecting direction is uncontrollable and the cooling effect is poor when the power density of the laser is relatively high in the prior art. The laser beam-expanding absorption device comprises an absorption cavity, a conical reflector, a magnetic meter stand, a beam expanding reflector II, a beam expanding reflector I and cooling fans. The conical cavity is combined with the beam-expanding absorption cavity; the power density of the laser can be reduced through beam expansion; and the laser can also be absorbed through the conical cavity, so that overflow of the laser is avoided to a great extent. In addition, a reflecting gap of the conical cavity is relatively small, so that the condition that the laser is completely absorbed by the absorption cavity finally after being reflected for a plurality of times is ensured.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

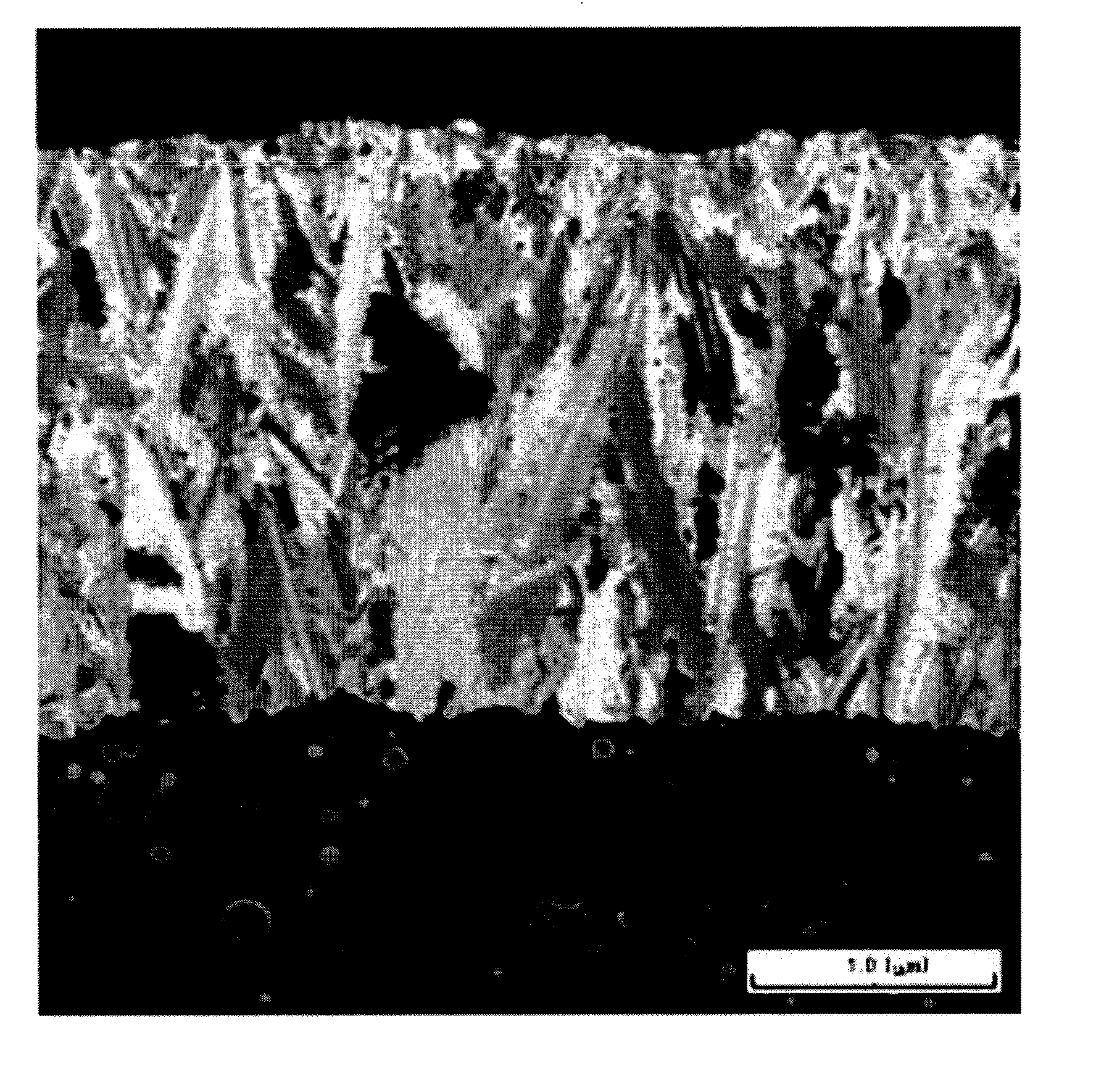

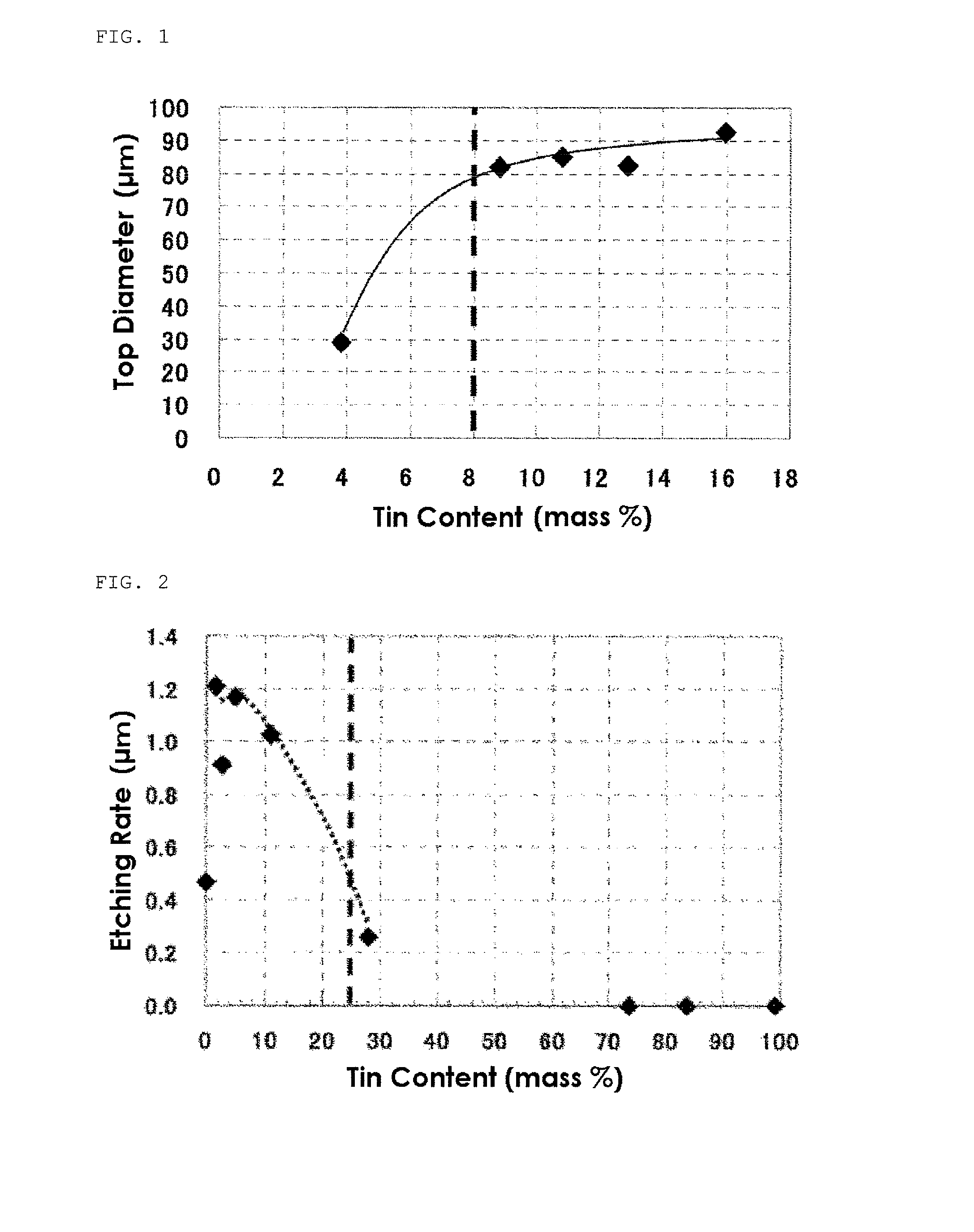

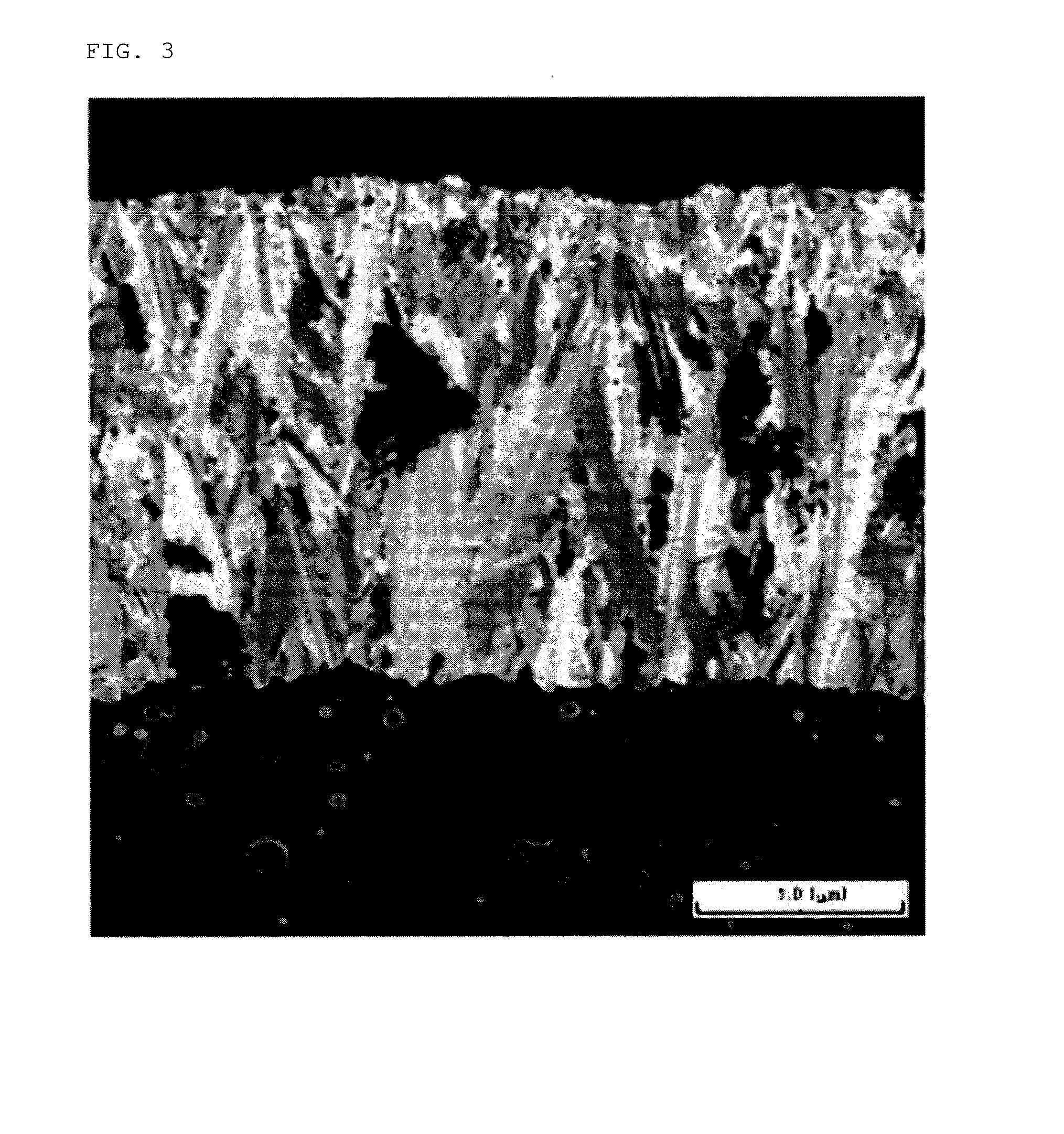

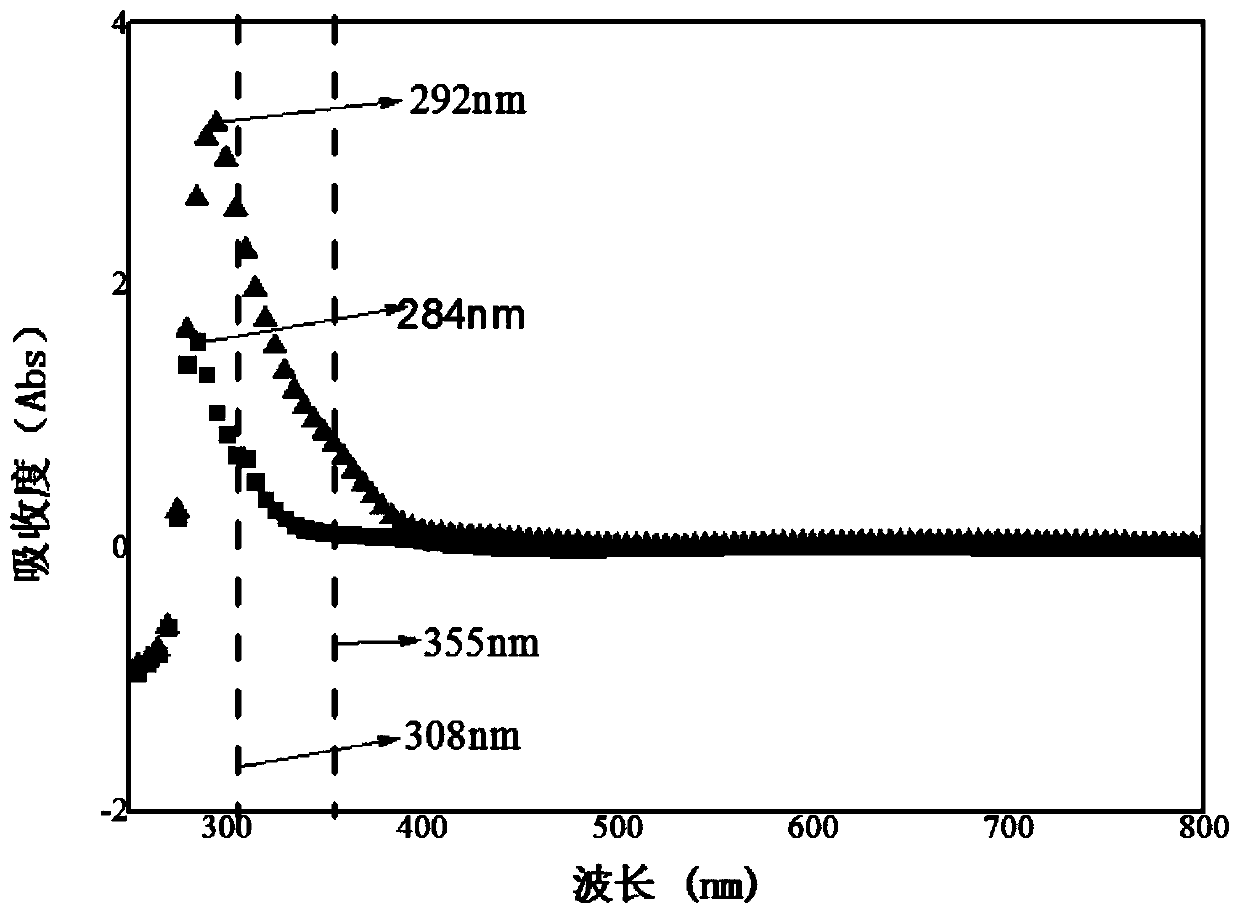

Electro-deposited copper-alloy foil and electro-deposited copper-alloy foil provided with carrier foil

InactiveUS20130171457A1Improve machinabilityEnhances infrared laser absorptivity efficiencyDuplicating/marking methodsActive material electrodesElectrolysisCrystal structure

An object of the present invention is to provide an electro-deposited copper-alloy foil excellent in infrared laser processability which enables uniform etching rate along a thickness direction in following etching process. To achieve the object, an electro-deposited copper-alloy foil obtained from electrolyzing of an electrolytic solution, wherein the electro-deposited copper-alloy foil has tin content of 8% by mass to 25% by mass is employed. In the electro-deposited copper-alloy foil, a grain in a crystal structure is preferably a columnar grain longitudinal along a thickness direction.

Owner:MITSUI MINING & SMELTING CO LTD

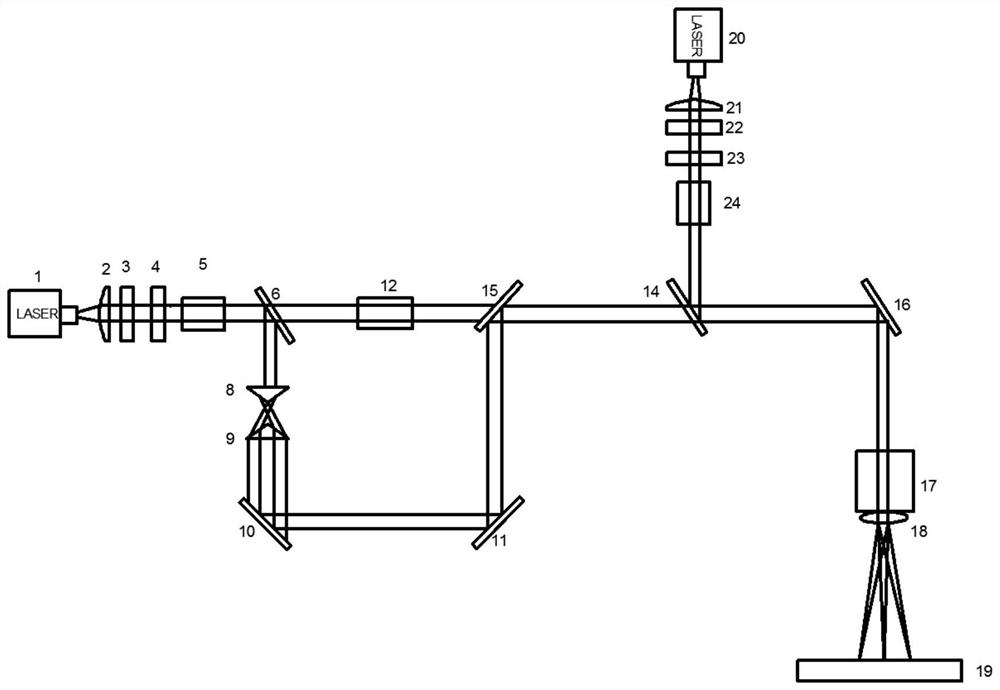

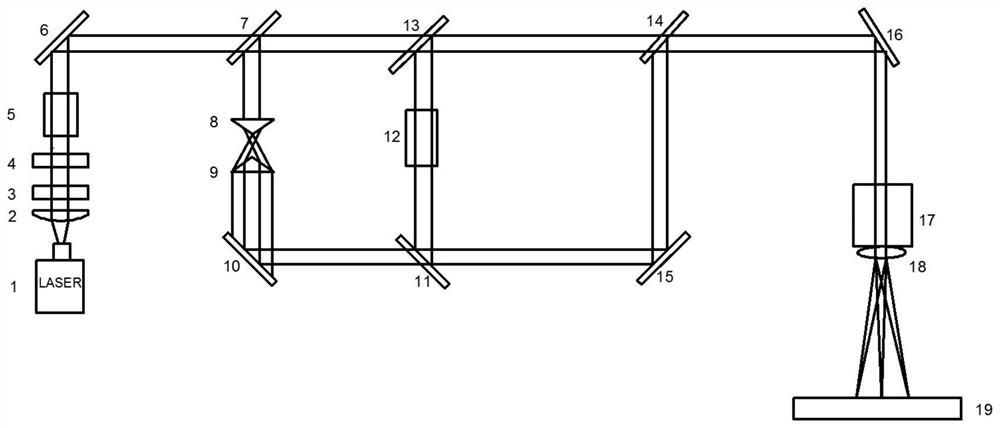

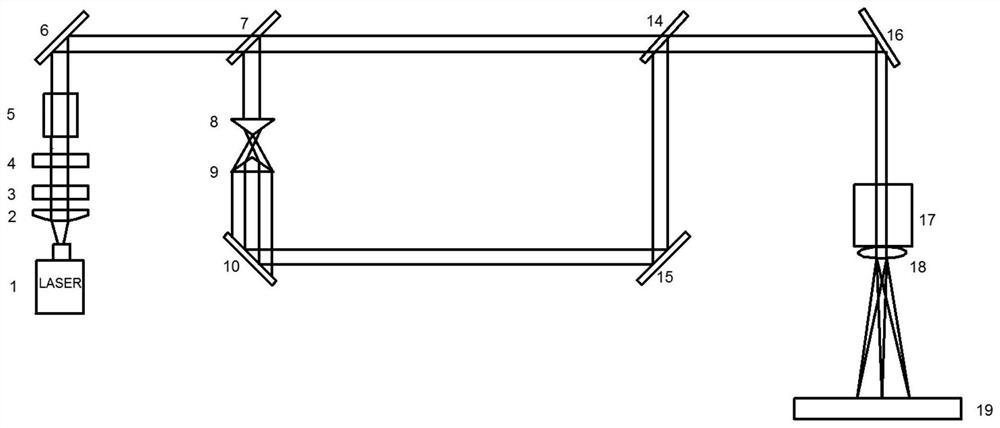

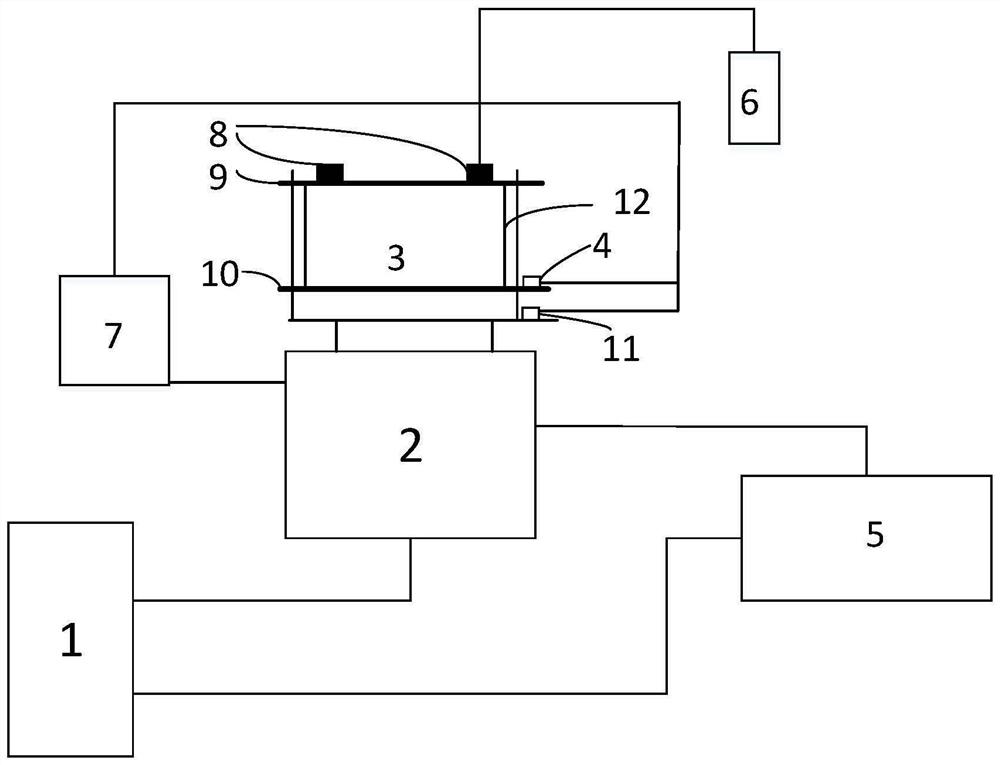

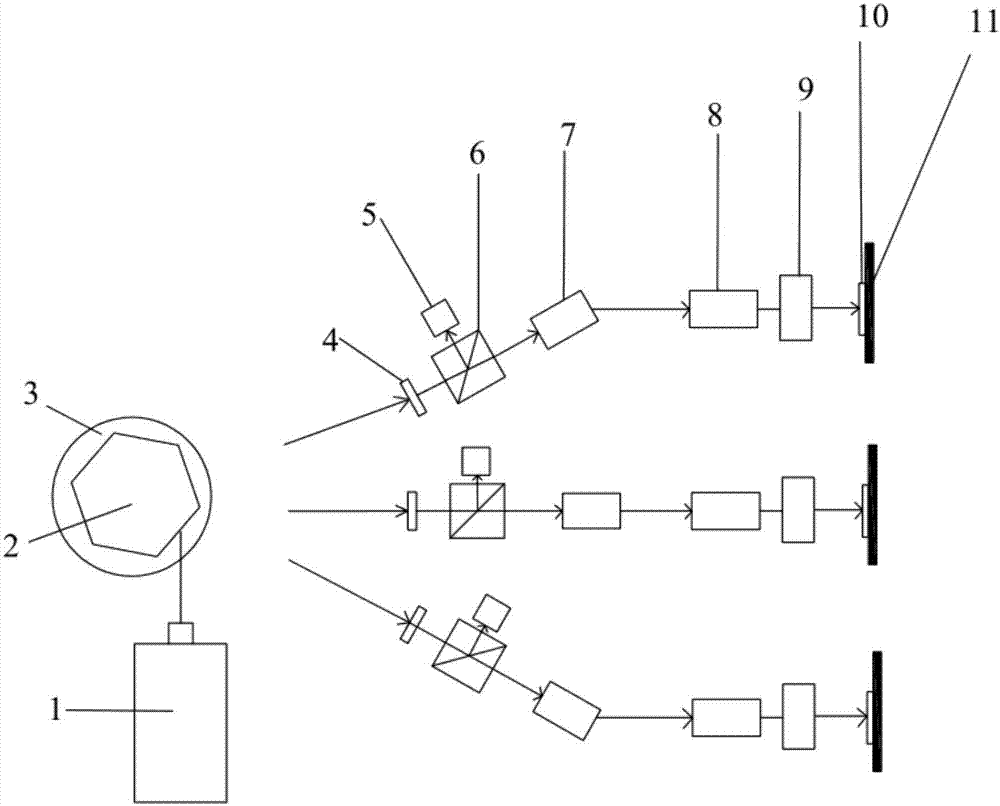

Metal SLM printing system based on Gaussian light beam and light beam shaping composite beam

PendingCN113634769AImprove energy utilizationImprove processing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyPolarizerOptical path

The invention discloses a composite light beam metal SLM printing system based on Gaussian light beam and light beam shaping and a dual-light-source composite light beam metal SLM printing system. The dual-light-source composite light beam metal SLM printing system comprises a light beam shaper, a light beam coupler and a Gaussian light beam metal SLM printing system, and the light beam shaper and the light beam coupler are sequentially arranged between a first variable magnification speed expanding mirror and a fifth total reflection mirror. A second Gaussian light emitting unit is arranged in the vertical direction of the light beam coupler and comprises a second laser, and a second collimator, a second half-wave plate, a second polarizer and a second variable magnification beam expander which are sequentially arranged in the propagation direction of Gaussian beams emitted by the second laser. The invention further provides a single-light-source composite light beam metal SLM printing system. The system can use a single light source and double light sources to freely combine Gaussian light, annular light and flat-top light, different light paths are freely switched on the basis of the light beam shaping technology, the printing speed, efficiency and quality of parts are improved, and application and popularization of the SLM technology are promoted.

Owner:GUANGXI UNIV

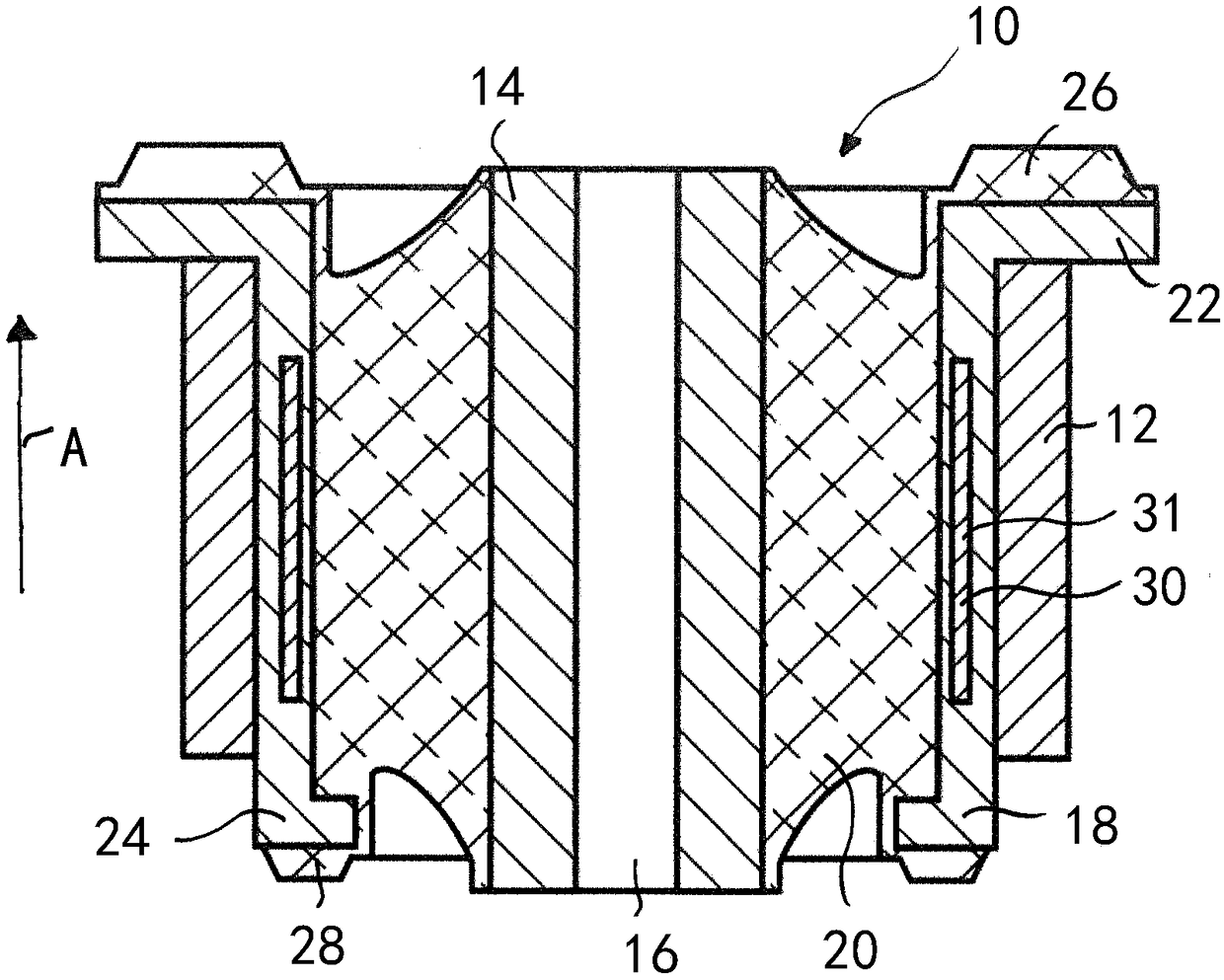

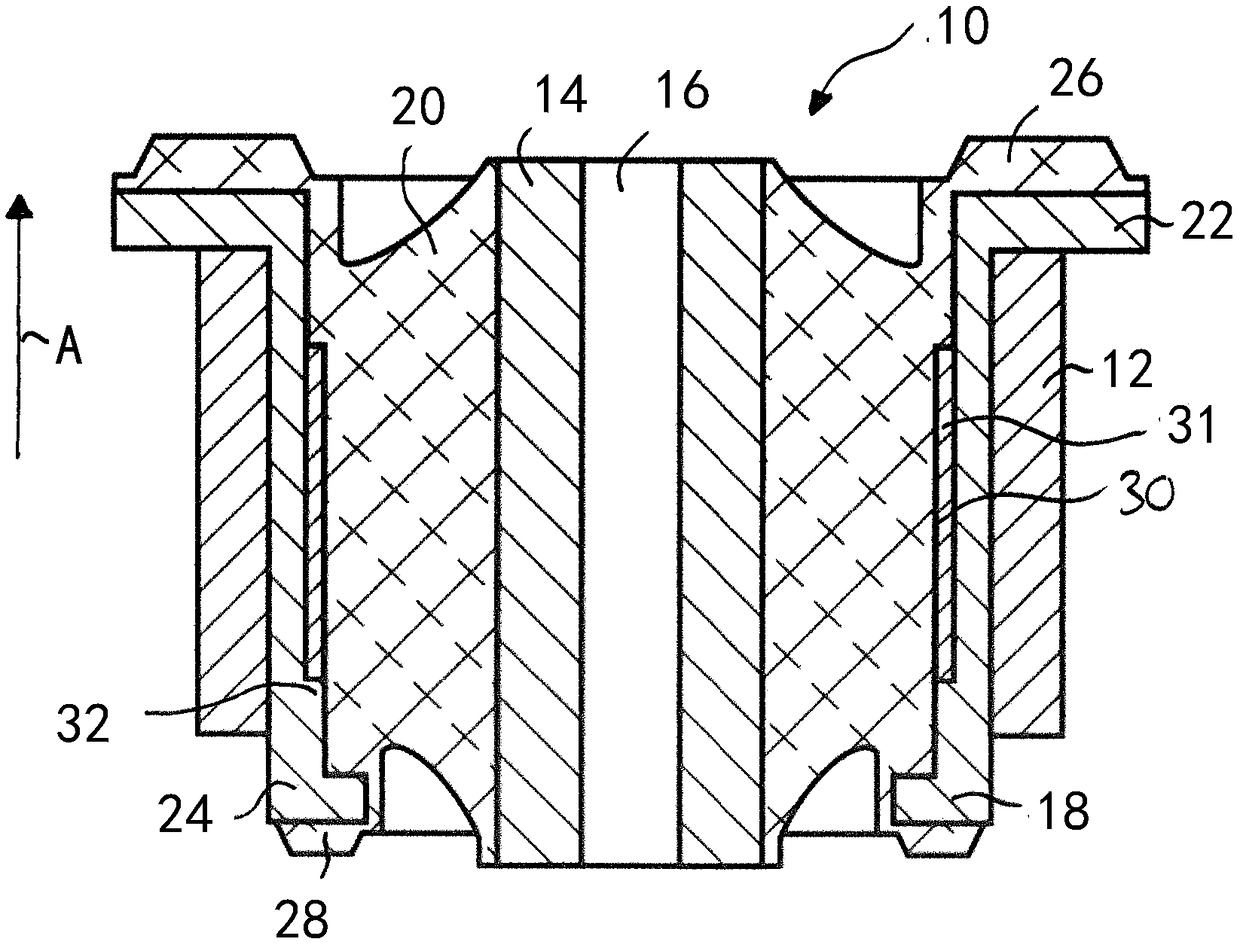

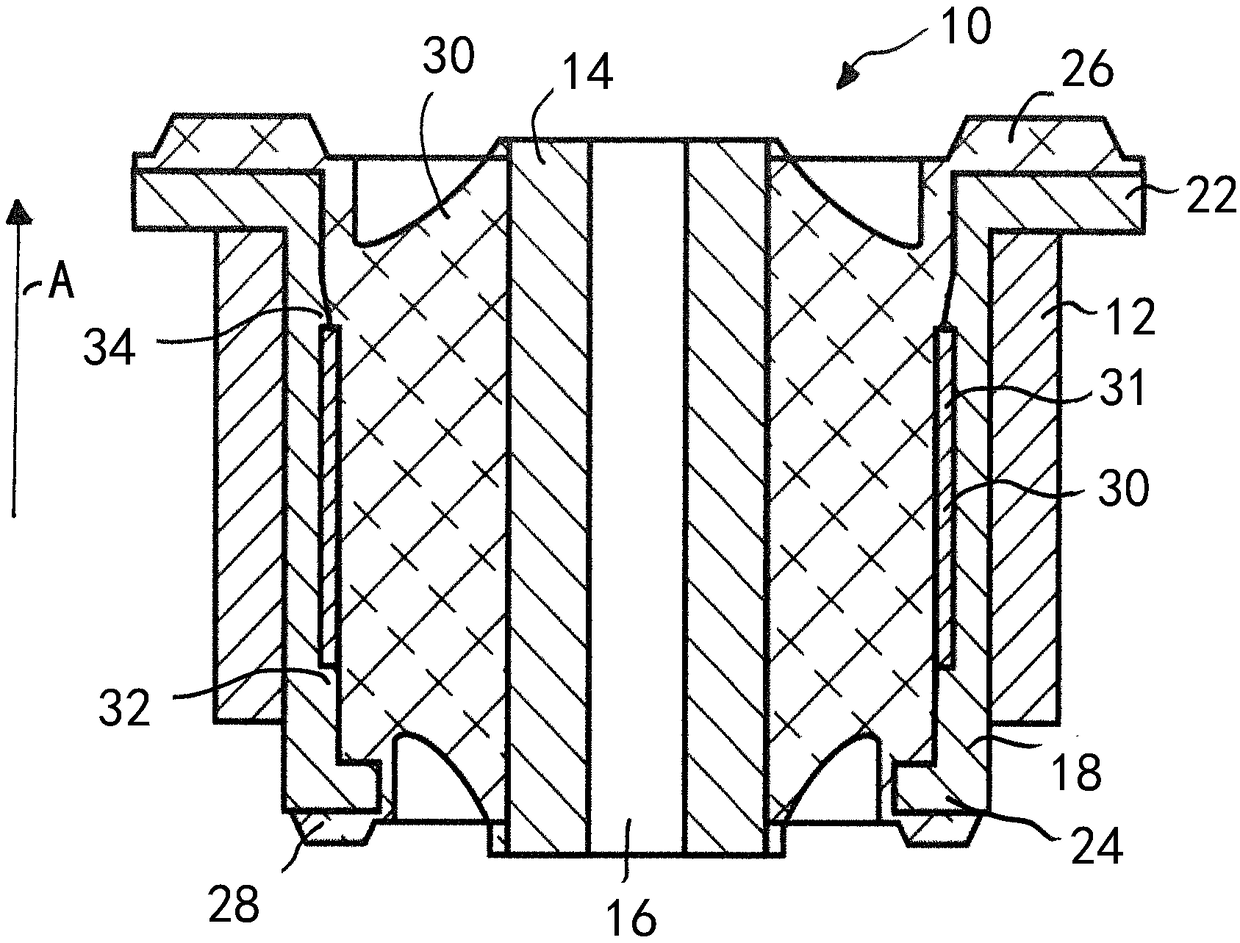

Bearing bush

InactiveCN109477536AHigh laser transmittanceImprove transmittanceRubber-like material springsElastomerChassis

The invention relates to a bearing bush (10) which is to be mounted in a receiving lug (12) in a chassis and which comprises a core (14), an outer sleeve (18) that surrounds the core (14) and is madeof a first material, and an elastomer part (20) that connects the core (14) and the outer sleeve (18) to each other, a supporting element (30) which is made of a second material radially supporting the outer sleeve (18) when the latter is pressed into the receiving lug (12).

Owner:VIBRACOUSTIC GMBH

Method for preparing in-situ Al matrix composite

Owner:SHANGHAI JIAOTONG UNIV +1

Laser stripping material as well as preparation method and application thereof

ActiveCN111534270AReduce fillingReduce thicknessNon-macromolecular adhesive additivesSolid-state devicesPolymer sciencePolyetherimide

The invention provides a laser stripping material as well as a preparation method and application thereof. The total mass of the laser stripping material is 100%. The laser stripping material comprises 1-40% of matrix resin, 0.1-10% of a light absorbing agent and 55-98% of a solvent, wherein the matrix resin comprises any one or a combination of at least two of polysulfone, polyamide, polyamide acid, polyimide, maleimide, polyetherimide, polybenzimidazole, polyacrylonitrile, polyetheretherketone, polyphenyl ether sulfone, polybenzoxazole, polyphenylene sulfide or polyetheretherketone. The laser stripping material is good in chemical resistance, excellent in heat resistance and high in laser absorptivity, the technical effect of low-energy laser debonding can be achieved, and damage of laser to a device layer is effectively avoided. Besides, when the laser stripping material is applied to preparation of a multi-layer ultrathin flexible device, the thickness of a stripping layer is small, cleaning is easy after laser scanning, and no material is left.

Owner:深圳市化讯半导体材料有限公司

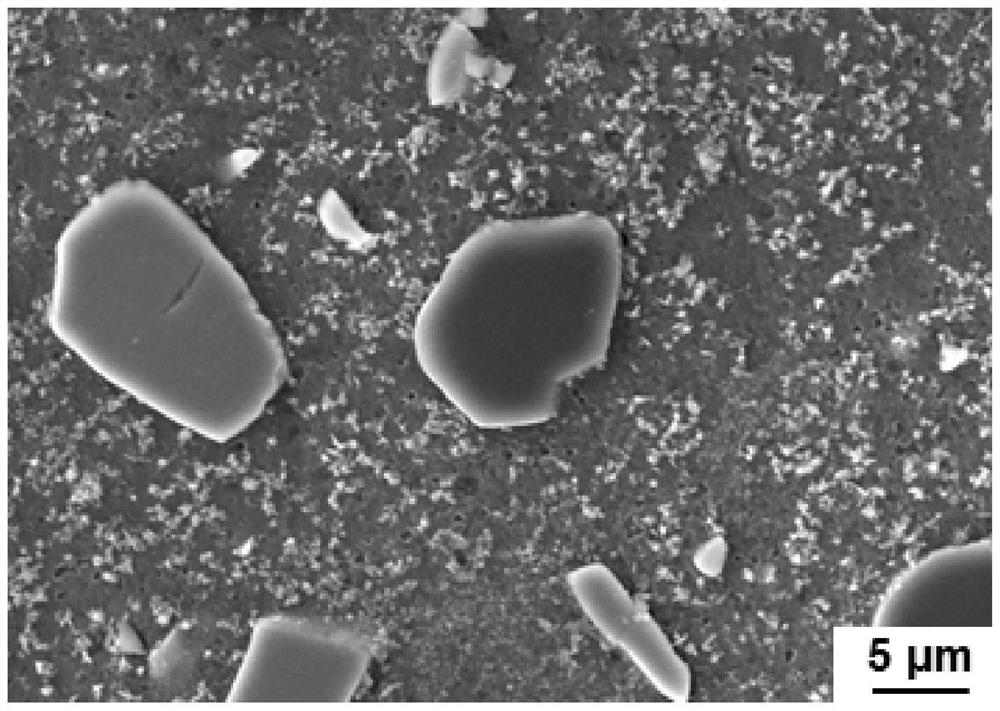

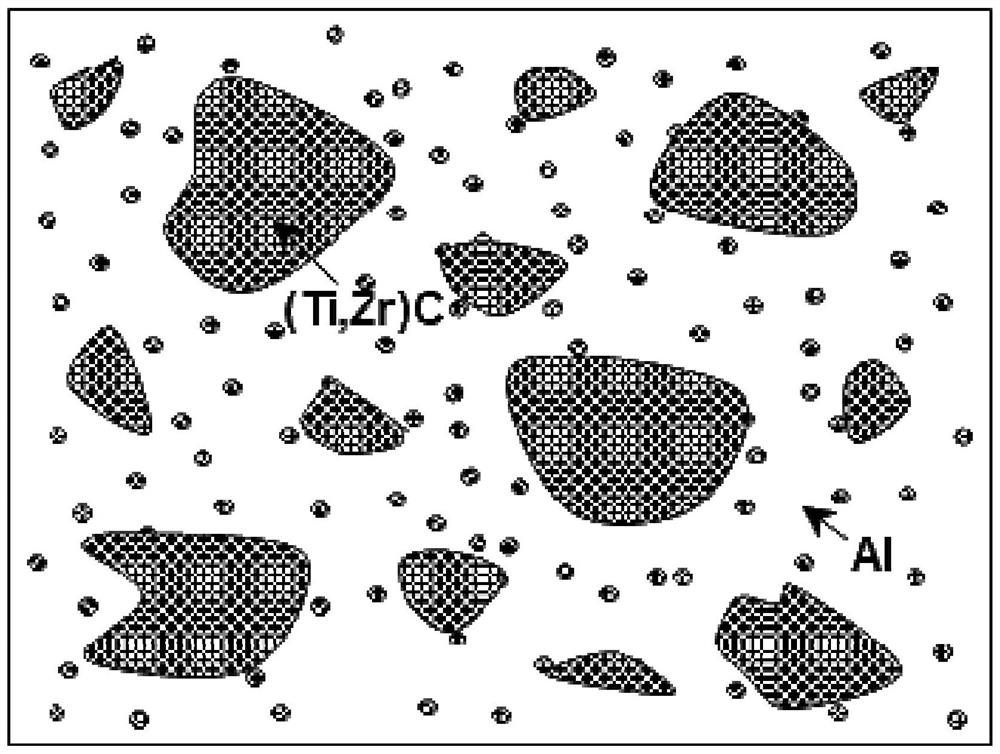

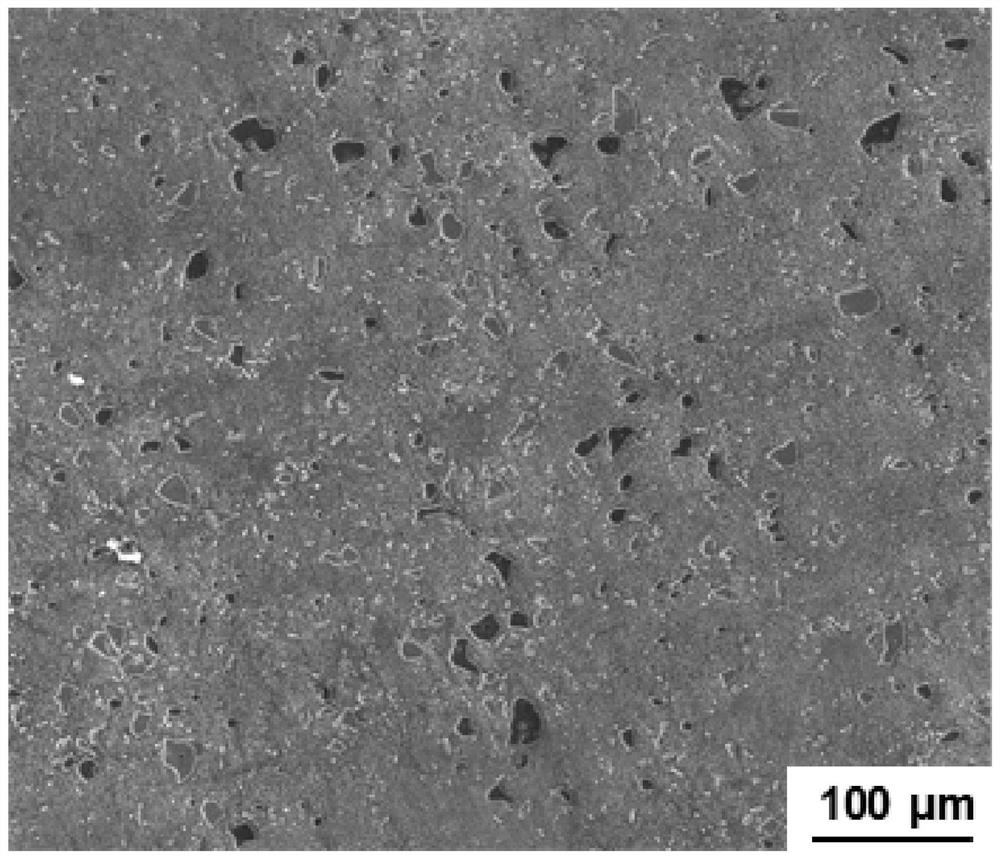

High-density cross-scale solid solution ceramic reinforced aluminum-based composite material and preparation method thereof

ActiveCN113881873AImprove forming qualityGood formabilityAdditive manufacturing apparatusIncreasing energy efficiencyHigh densityAluminium matrix

The invention discloses a high-density cross-scale solid solution ceramic reinforced aluminum-based composite material and a preparation method thereof. The high-density cross-scale solid solution ceramic reinforced aluminum-based composite material comprises an aluminum matrix as well as a TiC ceramic reinforced phase and a ZrC ceramic reinforced phase which are dispersed in the aluminum matrix; the TiC ceramic reinforced phase accounts for 4-8wt.% of the total mass of the composite material; the ZrC ceramic reinforced phase accounts for 6-12wt.% of the total mass of the composite material. According to the method, ZrC and TiC ceramic reinforced phases are added into the aluminum matrix, in the laser forming process, the ZrC and TiC reinforced phases are subjected to solid solution, a high-density cross-scale (Ti,Zr)C solid solution is generated, the strengthening effect of solid solutions of different sizes is exerted, and finally, the effect of improving the mechanical property of the material is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mixed powder for additive manufacturing and preparation method thereof

ActiveCN114045424AQuality impactWell mixedAdditive manufacturing apparatusTransportation and packagingManufacturing technologyProcess engineering

The invention discloses mixed powder for additive manufacturing and a preparation method thereof. According to the method, efficient and uniform mixing of the powder is achieved through vibration, and meanwhile the fluidity of the powder is guaranteed for the additive manufacturing technology to use. The method is suitable for flexible and simple requirements on powder component regulation and control in scientific research, and is also suitable for high-efficiency and large-scale requirements in industrial production. The original sphericity and fluidity of the powder are not changed while the component regulation of the powder is realized. For a powder bed additive manufacturing technology, the powder spreading quality of powder, namely uniform spreading and high stacking density of a powder layer, can not be damaged; and for the synchronous powder feeding additive manufacturing technology, the stability of powder feeding can be maintained, the risk of powder blockage of the powder nozzle is reduced, and therefore it is guaranteed that the mixed powder meets the requirement for additive manufacturing formability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

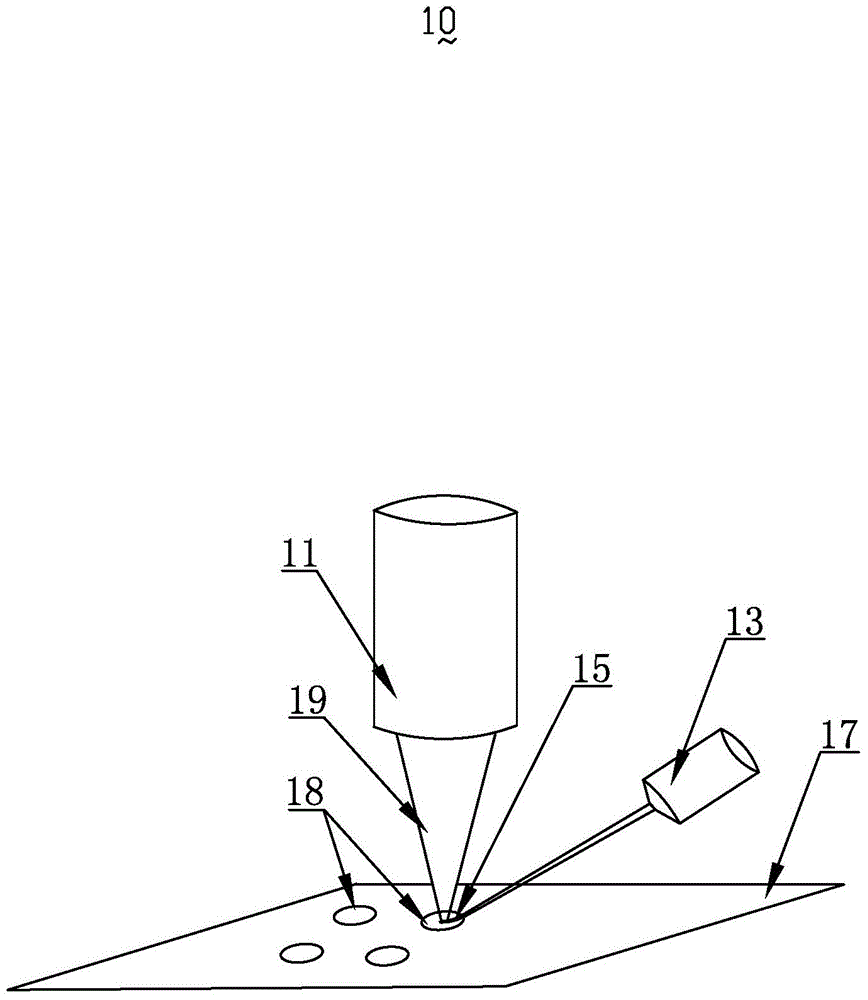

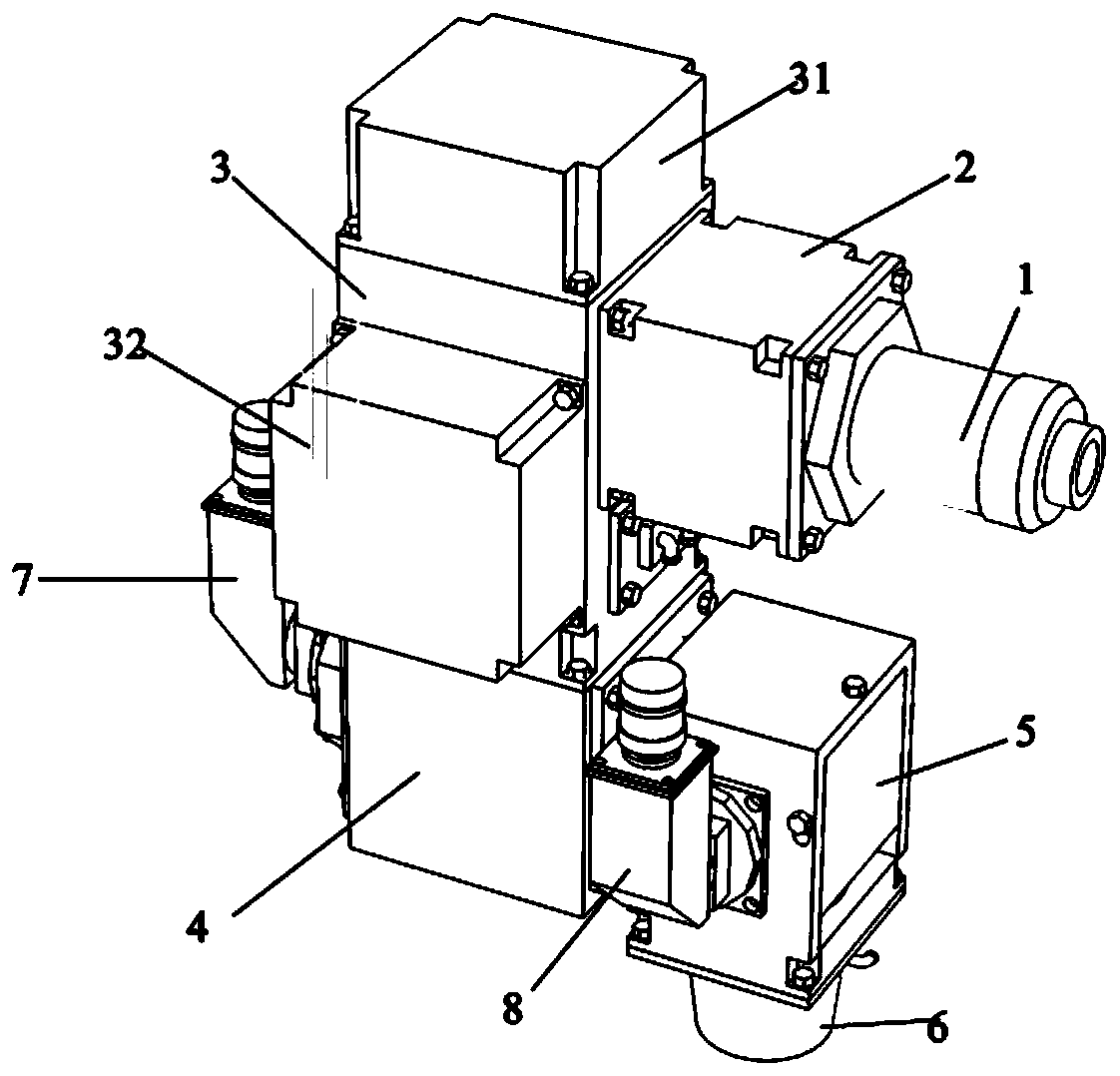

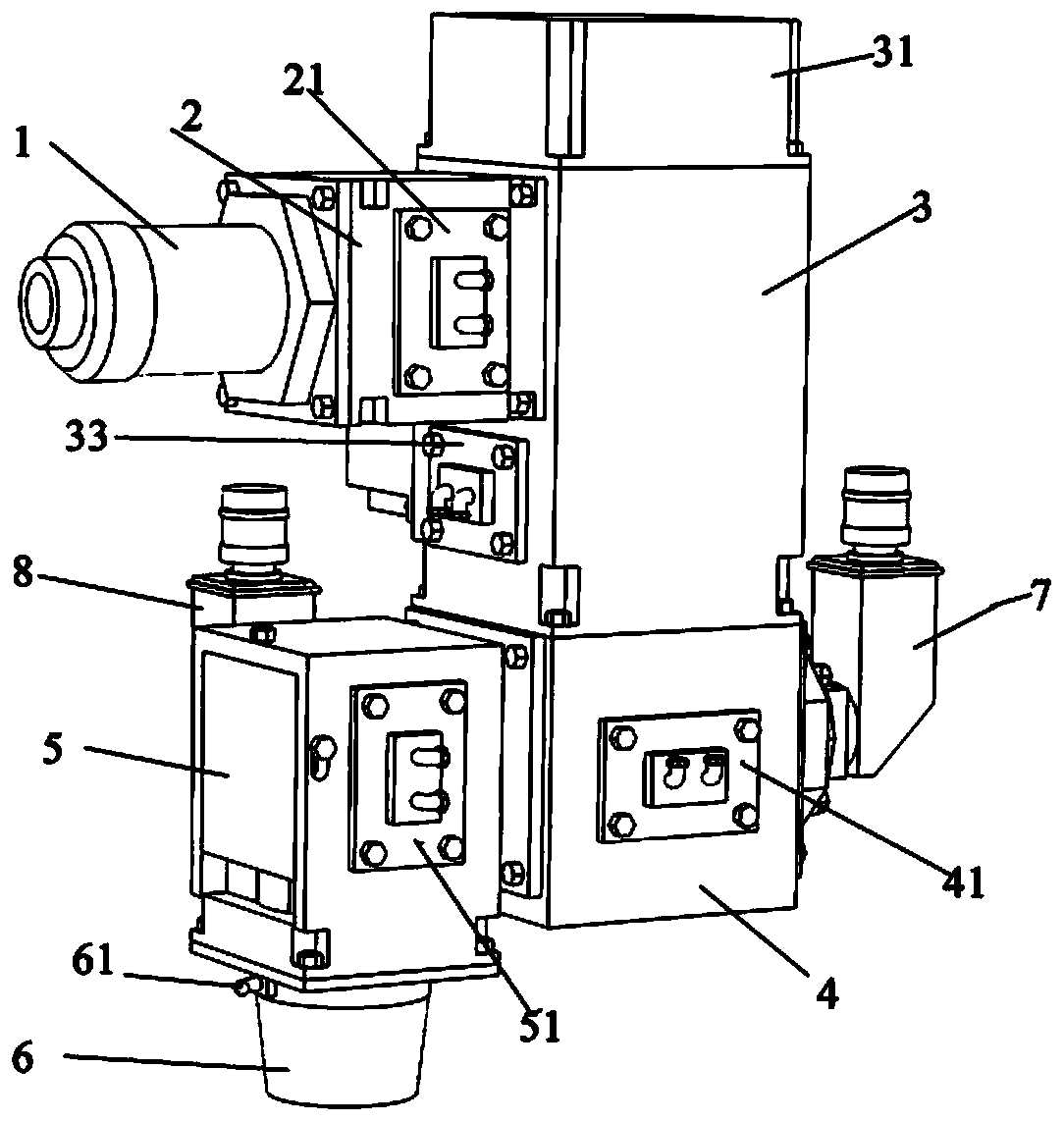

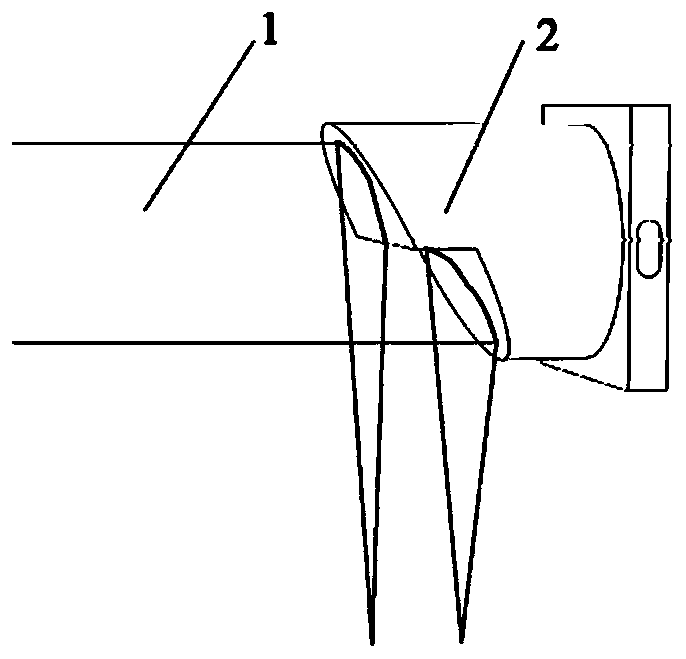

Laser cleaning-texturing composite machining head

ActiveCN110420935AImprove laser absorption rateGuaranteed cleanlinessLaser beam welding apparatusCleaning processes and apparatusLaser processingGalvanometer

The invention discloses a laser cleaning-texturing composite machining head and relates to the field of laser. The laser cleaning-texturing composite machining head aims to solve the problems that after laser cleaning, laser texturing machining needs to be performed or before laser texturing, laser cleaning machining needs to be performed, a manufactured material is poor in surface quality, the machining efficiency is low, and the running cost is high. The laser cleaning-texturing composite machining head comprises a laser interface, a collimating mirror assembly, a galvanometer assembly, a reflecting mirror assembly, a light splitting focusing lens assembly, a dust removing adsorbing assembly, a first CCD camera assembly and a second CCD camera assembly. A light splitting focusing deviceis designed in the laser cleaning-texturing composite machining head, the advantages of laser cleaning and laser texturing are played, and the purposes of simplifying the process, saving cost, savingtime, improving efficiency, and improving the cleaning and texturing quality are achieved. The laser cleaning-texturing composite machining head is applied in the laser machining field.

Owner:HARBIN INST OF TECH

Short-wavelength efficient stable high-reflectivity metal laser welding system

PendingCN107971631AReduce lossLaser output power is stableLaser beam welding apparatusBeam splittingPrism

Owner:CHANGZHOU INNO MACHINING +1

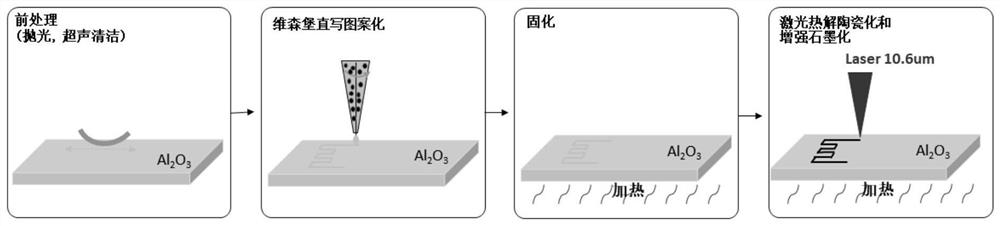

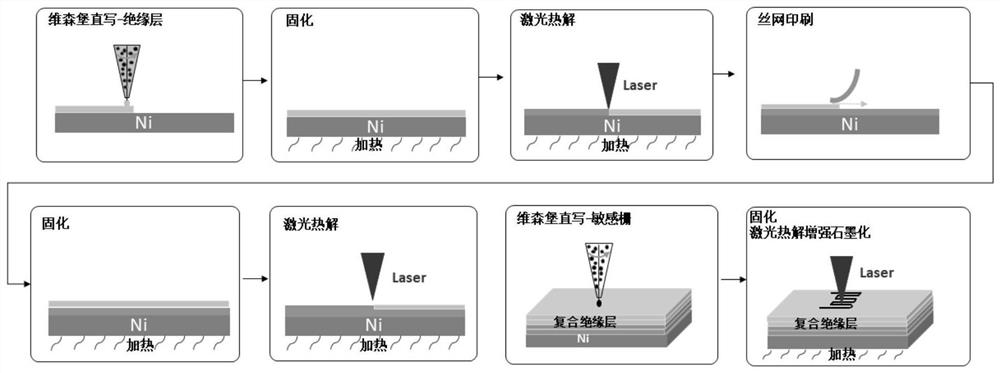

Laser pyrolysis composite additive manufacturing integrated precursor ceramic film sensor and preparation method thereof

PendingCN114322741AReduce the impactEasy to changeAdditive manufacturing apparatusForce measurementMetallic materialsThin membrane

The invention discloses a laser pyrolysis composite additive manufacturing integrated precursor ceramic film sensor and a preparation method thereof, a metal component or an insulating material is used as a substrate, and a PDC doped composite insulating film layer with high compactness, high insulativity and high temperature resistance is formed on the surface of the metal component through a layer-by-layer laser pyrolysis additive technology; a sensitive grid of PDC doped filler is directly written on the composite insulating film layer through Vensengburg, and a strain sensitive layer with excellent conductivity is obtained through a method for enhancing PDC graphitization through laser pyrolysis, so that laser in-situ additive integrated manufacturing of the high insulating film layer based on the PDC material, the sensitive grid with excellent conductivity and the metal substrate is created; the laser technological process of liquid-solid-function conversion of the PDC composite material is achieved, and the PDC composite material is successfully applied to metal material strain sensing.

Owner:XIAMEN UNIV

High-energy laser beam expanding and absorbing device

InactiveCN103389157BHigh measurement accuracyAchieve absorptionOptical elementsHigh power lasersEnergy absorption

The invention discloses a high-energy laser beam expanding and absorbing device which comprises a laser beam expanding cone, an energy absorption cavity, a front panel and a fixing plate, wherein the energy absorption cavity adopts a hollow cylinder; the front panel is arranged at a laser incident end of the energy absorption cavity, and the fixing plate is arranged at the rear end of the energy absorption cavity and used for fixing the laser beam expanding cone; and the laser beam expanding cone comprises a pointed beam expanding cone, at least two spherical beam expanding cones and cylinder transition sections which are arranged in the laser incident direction sequentially, and radii of cylinders of the cylinder transition sections are increased gradually in the laser incident direction. The laser beam expanding cone simultaneously realizes beam expanding of incident laser beams in the length direction and the circumference direction of the absorption cavity, and effectively reduces the power density of laser shot to a heat absorption cylinder by the laser beam expanding cone; and by means of the high-energy laser beam expanding and absorbing device, absorption and conduction of hundred thousand joules to a megajoule of high-power laser energy of continuous waves are realized, the measuring accuracy of an energy meter is improved greatly, and the device has wide applicability.

Owner:NORTHWEST INST OF NUCLEAR TECH

Method for preparing high-performance in-situ TIC-reinforced titanium matrix composite workpieces based on cnts and laser additive manufacturing processing technology

ActiveCN105033254BGood interface wettabilityTightly boundAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesCarbon nanotube

The invention discloses a method for manufacturing a high-performance in-situ TiC reinforced titanium-based composite workpiece on the basis of CNTs and a laser additive manufacturing and processing technology. The method includes the following steps that (1) the carbon nano tubes are subjected to preliminary ultrasonic dispersion treatment; (2) pure titanium powder with the average particle size of 45-75 microns is mixed with the carbon nano tubes to obtain a mixture, and CNTs / Ti mixed powder is obtained by ball-milling the mixture through a ball mill under the protection of argon; and (3) the ball-milled CNTs / Ti mixed powder is shaped through a laser additive manufacturing and processing method so as to obtain a high-performance in-situ TiC reinforced titanium-based composite body. The method has the advantages that in-situ TiC reinforcement phases are formed on the basis of a CNTs in-situ reaction and evenly distributed in a titanium substrate, and the interface bonding strength is high; grains of a composite are refined remarkably; net forming or near-net forming of a test piece can be achieved; any complex heterogeneous part can be formed.

Owner:南京瑞德增域三维技术发展有限公司

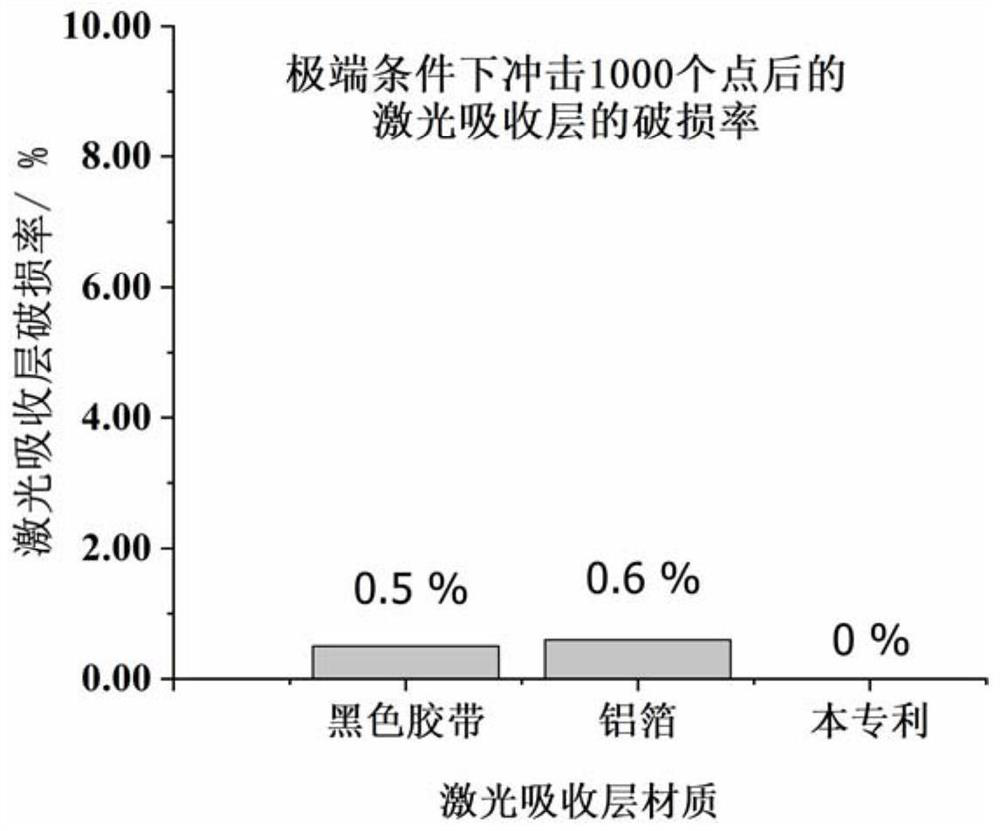

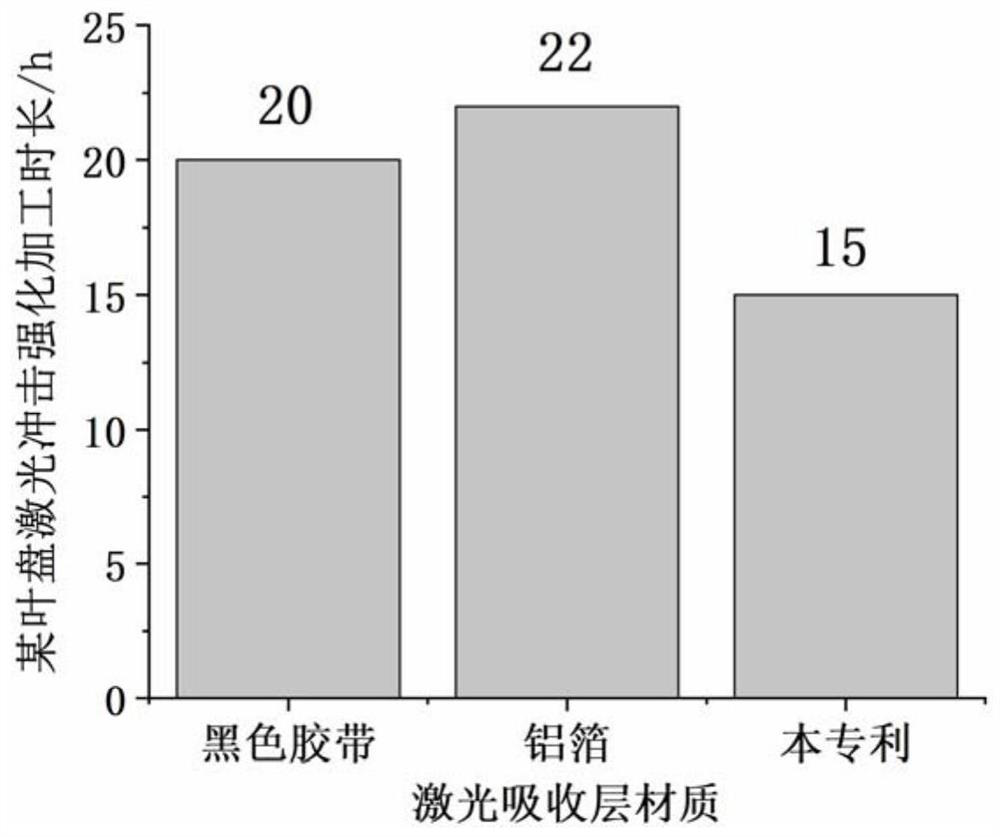

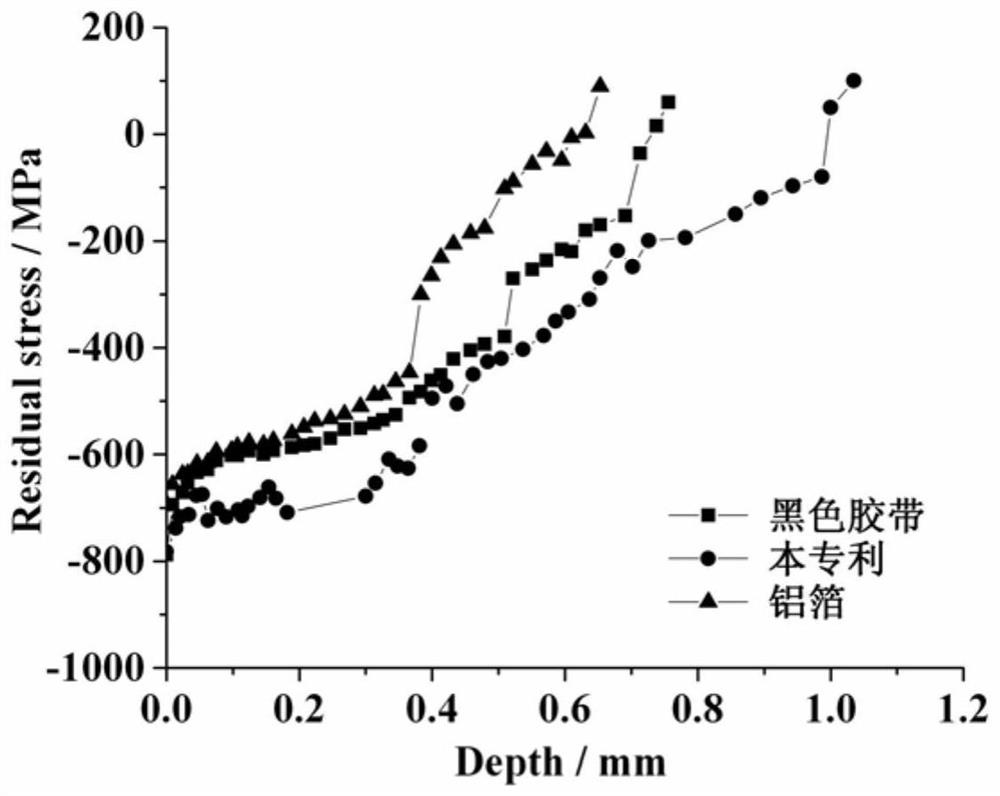

Graphene modified laser absorption layer coating and coating method thereof

ActiveCN113088172AImprove laser absorption rateImprove the utilization rate of laser energyLiquid surface applicatorsPolyurea/polyurethane coatingsGrapheneGraphite

The invention belongs to the technical field of part surface treatment, and relates to a graphene modified laser absorption layer coating and a coating method thereof. The coating is mainly composed of polyurethane resin, a black auxiliary material, a functional auxiliary agent and deionized water. After graphene modification, higher amplitude and deeper surface residual compressive stress distribution are generated on the surface of the part. The laser absorption layer coating is coated on the surface of a part in a high-pressure gas driven spraying mode, a coating with uniform thickness is obtained on the surface of a complex part after drying, the binding force between the coating and the part is good, and the coating can be removed through manual stripping after laser shock is completed. The method has the advantages of being high in coating efficiency, good in quality reliability, high in removal efficiency and the like, and machining and mass production of complex parts are facilitated.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

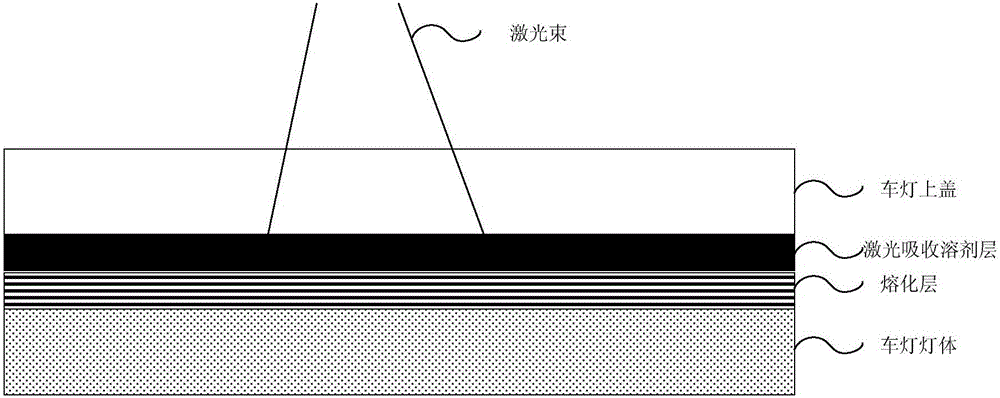

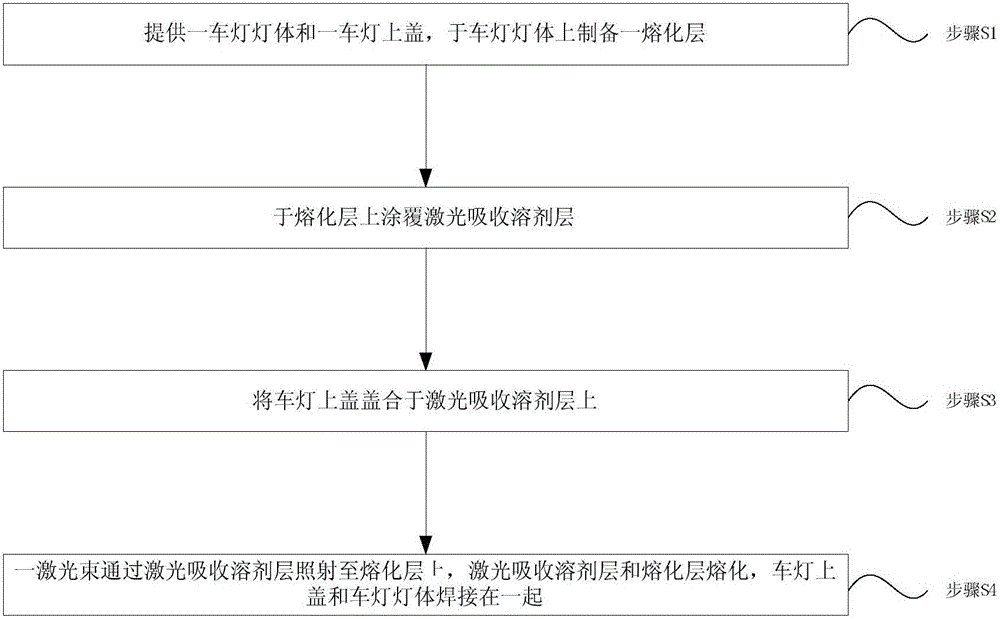

Automotive lamp product and welding method thereof

ActiveCN105965158AImprove laser absorption rateExcellent adhesionProtective devices for lightingOptical signallingEngineeringSolvent

The invention relates to the field of automotive lamp packaging, in particular to an automotive lamp product and a welding method thereof. According to the automotive lamp product and the welding method thereof, a fusion layer is coated with a laser absorption solvent layer, so that absorption for laser beams is enhanced; the fusion layer and the laser absorption solvent layer can be fused together completely; adhesion, between a lamp body of an automotive lamp and an upper cover of the automotive lamp, generated during laser welding is enhanced; and the upper cover of the automotive lamp is prevented from falling off the lamp body of the automotive lamp in the using process of an automotive lamp product.

Owner:SHANGHAI SEEYAO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com