Aluminum-based composite material powder for laser reinforcement manufacturing and preparation method thereof

An aluminum-based composite material and laser additive technology, applied in the field of materials, can solve the problems of high residual stress cracks and holes, insufficient reliability, and high cost, and achieve the effect of improving the laser absorption rate, expanding the scope of application, and improving the strength of the material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

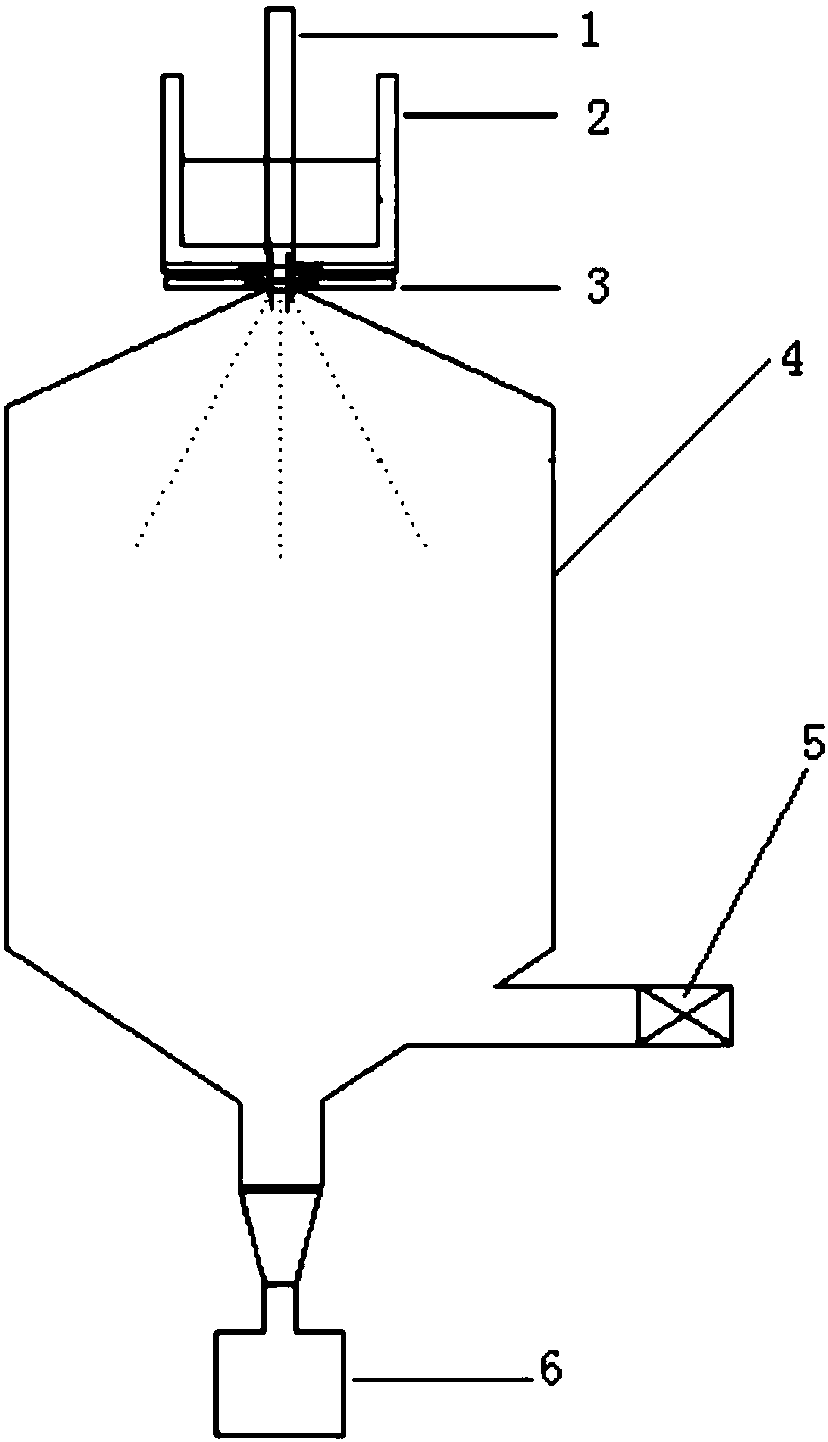

[0042] This embodiment provides an aluminum-based composite material powder for laser additive manufacturing, and its preparation method includes:

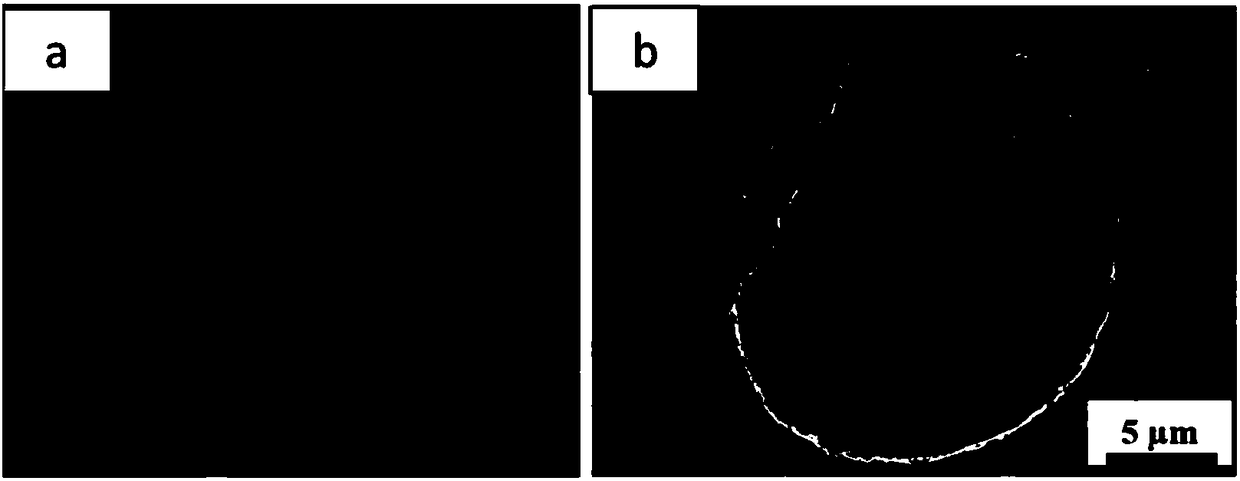

[0043] With high purity Al, industrial pure Mg, Al-12Zr master alloy, KBF 4 And K 2 TiF 6 Prepared 5wt.% TiB in situ for raw materials 2 Reinforce Al-2.2Mg-0.1Zr composite material. Put the high-purity Al in a crucible to melt and heat it to 780℃, and cover it with JZF-03 high-temperature covering agent; put KBF 4 , K 2 TiF 6 After mixing uniformly according to the mass ratio of 1:2, adding to the melt obtained in the previous step after drying; after the reaction is over, take out the reaction by-products, add Al-12Zr master alloy and industrial pure Mg in turn, and add JZJ to the melt Type harmless aluminum alloy refining agent for degassing refining, standing at 750°C for 15 minutes, and then making powder through a gas atomization device. The above-mentioned Al-2.2Mg-0.1Zr means that the mass fraction of Mg is 2.2%, the mass frac...

Embodiment 2

[0047] This embodiment provides an aluminum-based composite material powder for laser additive manufacturing, and its preparation method includes:

[0048] With high purity Al, industrial pure Mg, Al-12Zr master alloy, KBF 4 And K 2 TiF 6 Prepared 5wt.% TiB in situ for raw materials 2 Reinforce Al-2.2Mg-0.09Zr composite material. Put the high-purity Al in a crucible to melt and heat it to 780℃, and cover it with JZF-03 high-temperature covering agent; put KBF 4 , K 2 TiF 6 After mixing uniformly according to the mass ratio of 1:2, adding to the melt obtained in the previous step after drying; after the reaction is over, take out the reaction by-products, add Al-12Zr master alloy and industrial pure Mg in turn, and add JZJ to the melt Type harmless aluminum alloy refining agent for degassing refining, standing at 750°C for 15 minutes, and then making powder through a gas atomization device. The gas atomization device is the same as in Example 1, and its gas atomization process is ...

Embodiment 3

[0051] This embodiment provides an aluminum-based composite material powder for laser additive manufacturing, and its preparation method includes:

[0052] With high purity Al, industrial pure Mg, Al-12Zr master alloy, KBF 4 And K 2 TiF 6 Prepared 5wt.% TiB in situ for raw materials 2 Reinforce Al-2.2Mg-0.09Zr composite material. Put the high-purity Al in a crucible to melt and heat it to 780℃, and cover it with JZF-03 high-temperature covering agent; put KBF 4 , K 2 TiF 6 After mixing uniformly according to the mass ratio of 1:2, adding to the melt obtained in the previous step after drying; after the reaction is over, take out the reaction by-products, add Al-12Zr master alloy and industrial pure Mg in turn, and add JZJ to the melt Type harmless aluminum alloy refining agent for degassing refining, standing at 750°C for 15 minutes, and then making powder through a gas atomization device. The aerosolization device is the same as in Example 1. The gas atomization process is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com