Laser cleaning-texturing composite machining head

A technology of laser cleaning and compound processing, which is applied in the laser field, can solve problems such as high operating cost, low processing efficiency, and poor surface quality, and achieve the effects of increasing laser absorption rate, improving efficiency, and shortening time intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

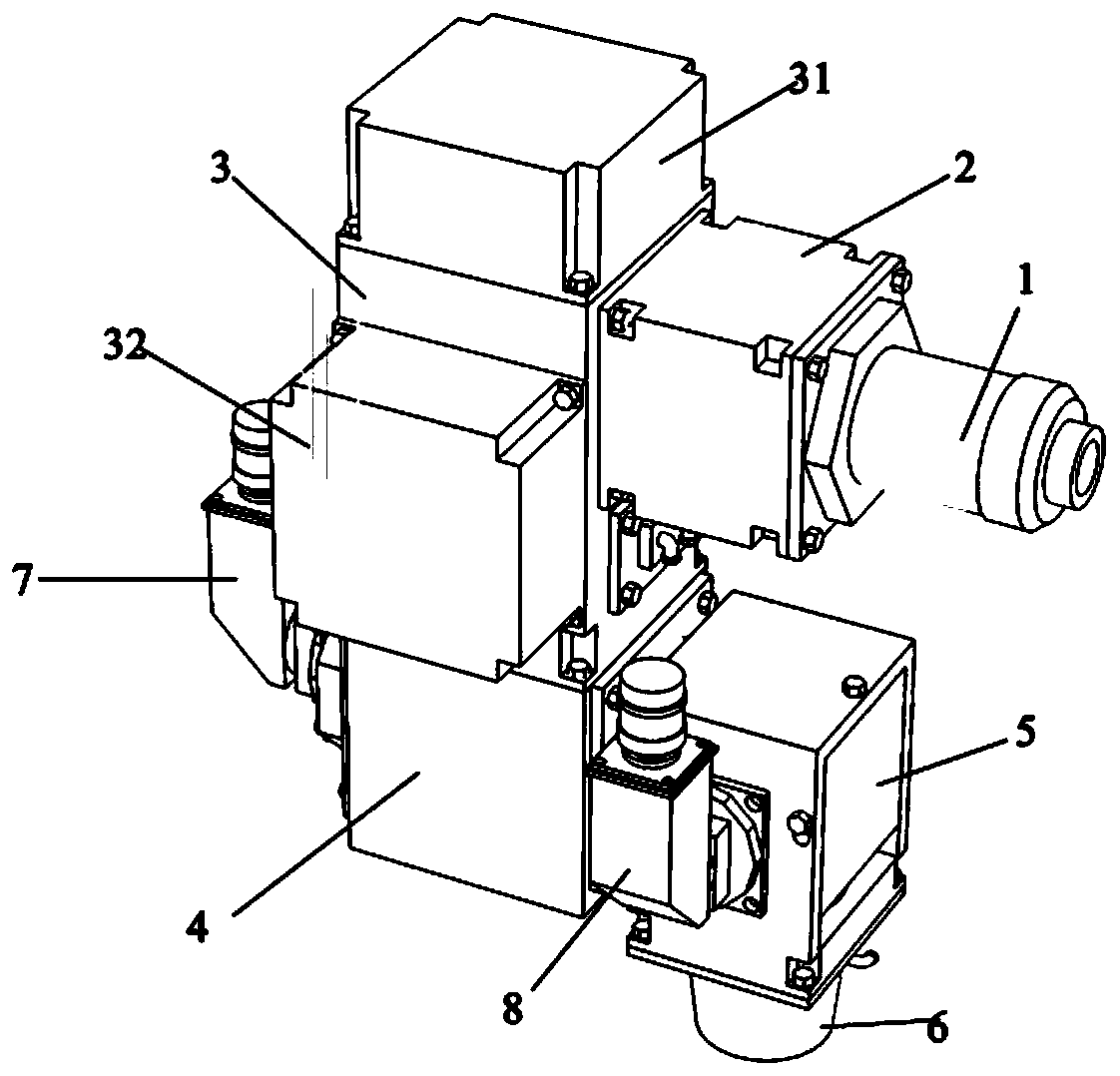

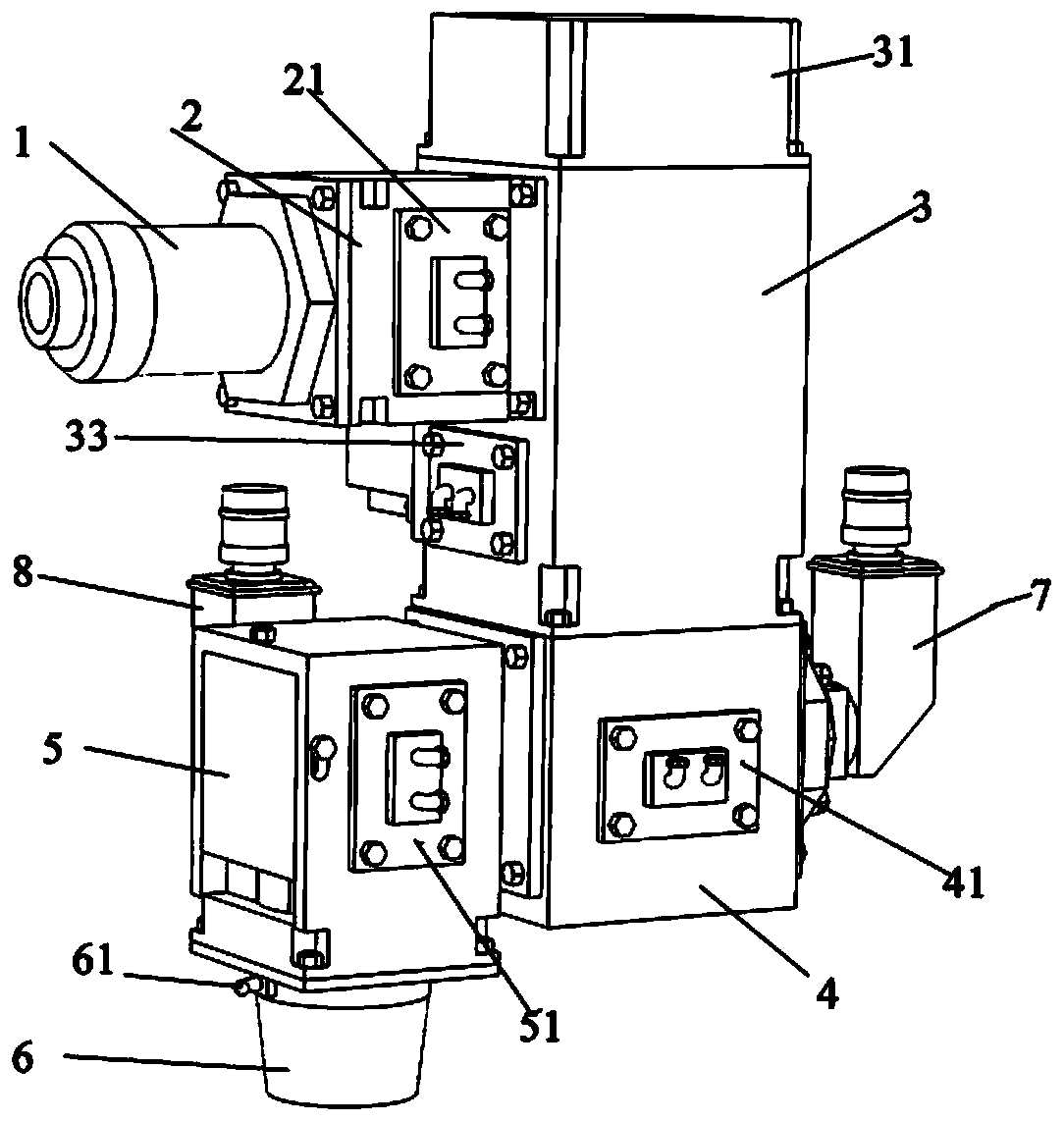

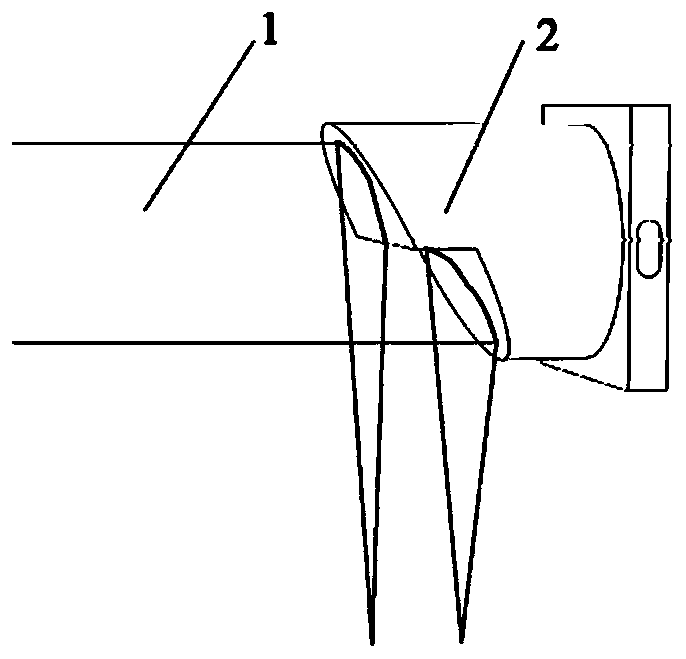

[0024] Specific implementation mode one: combine Figures 1 to 4 Describe this embodiment, a laser cleaning-texturing composite processing head of this embodiment, which includes a laser interface 1, a collimating mirror assembly 2, a vibrating mirror assembly 3, a reflecting mirror assembly 4, a spectroscopic focusing mirror assembly 5, a dust removal and adsorption Component 6, CCD camera component one 7 and CCD camera component two 8;

[0025] One end of the laser interface 1 is connected to the laser, and the other end is connected to the collimating mirror assembly 2; the collimating mirror assembly 2 is connected to the vibrating mirror assembly 3; The rear end of the focusing mirror assembly 5 is connected, and the bottom of the spectroscopic focusing mirror assembly 5 is connected with the dust removal and adsorption assembly 6; the CCD camera assembly one 7 is arranged on the rear part of the spectroscopic focusing mirror assembly 5, and the CCD camera assembly two 8 ...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination Figures 1 to 4Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the cleaning laser power is 100-500W, and the moving speed of the light spot is 100-3000mm / min; the textured laser power is 300-1000W, and the moving speed of the light spot is 100-3000mm / min; the total power of the laser beam is 400-1500W.

[0032] Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figures 1 to 4 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the cleaning laser power is 300-500W, and the moving speed of the spot is 500-3000mm / min; the texturing laser power is 500-1000W, and the moving speed of the spot is 500-3000mm / min; the total power of the laser beam is 1000-1500W.

[0034] Other compositions and connection methods are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com