Bearing bush

A technology for bushings and outer sleeves, applied to springs, springs, springs/shock absorbers made of plastic materials, etc., which can solve problems such as complex outlines of outer sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

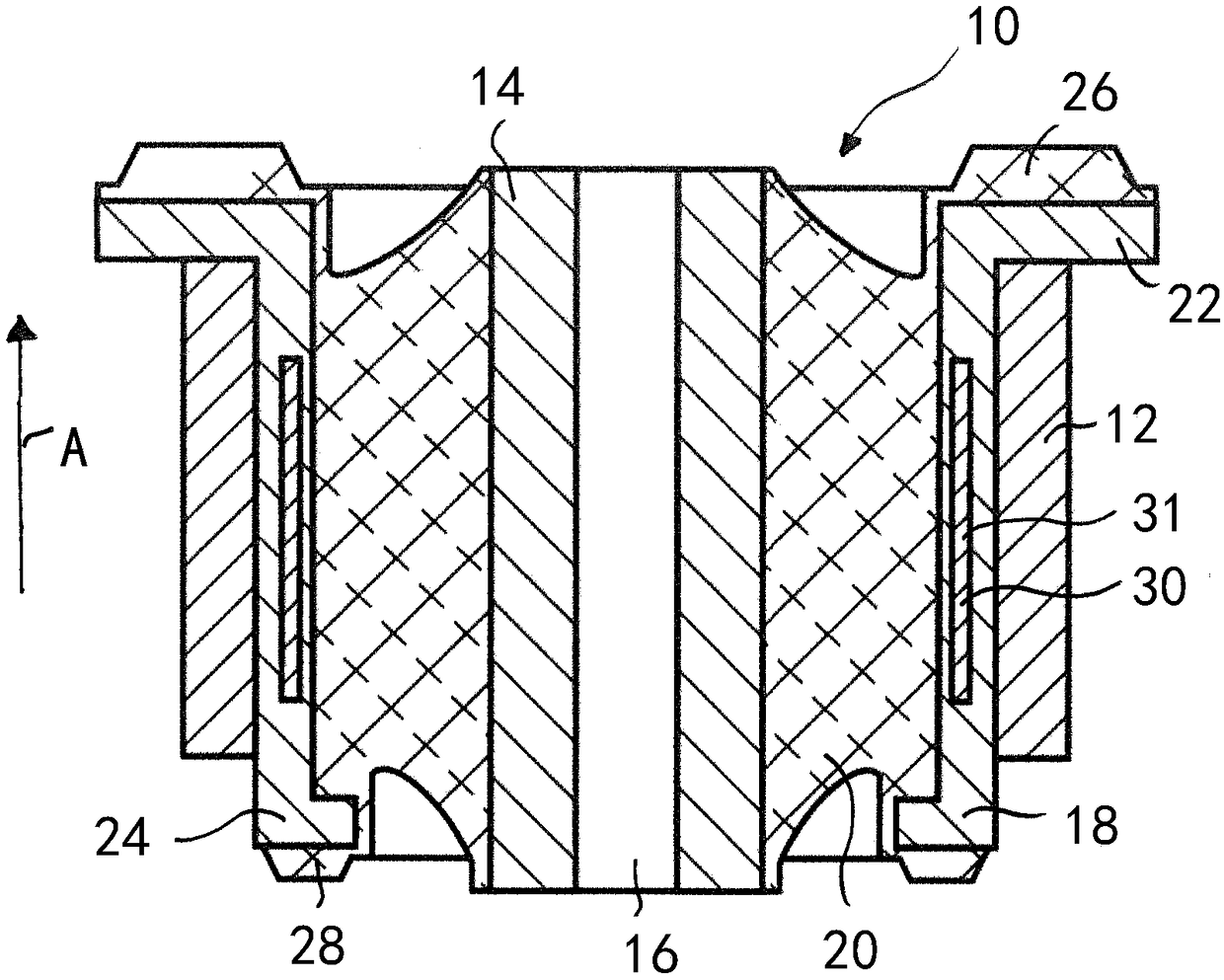

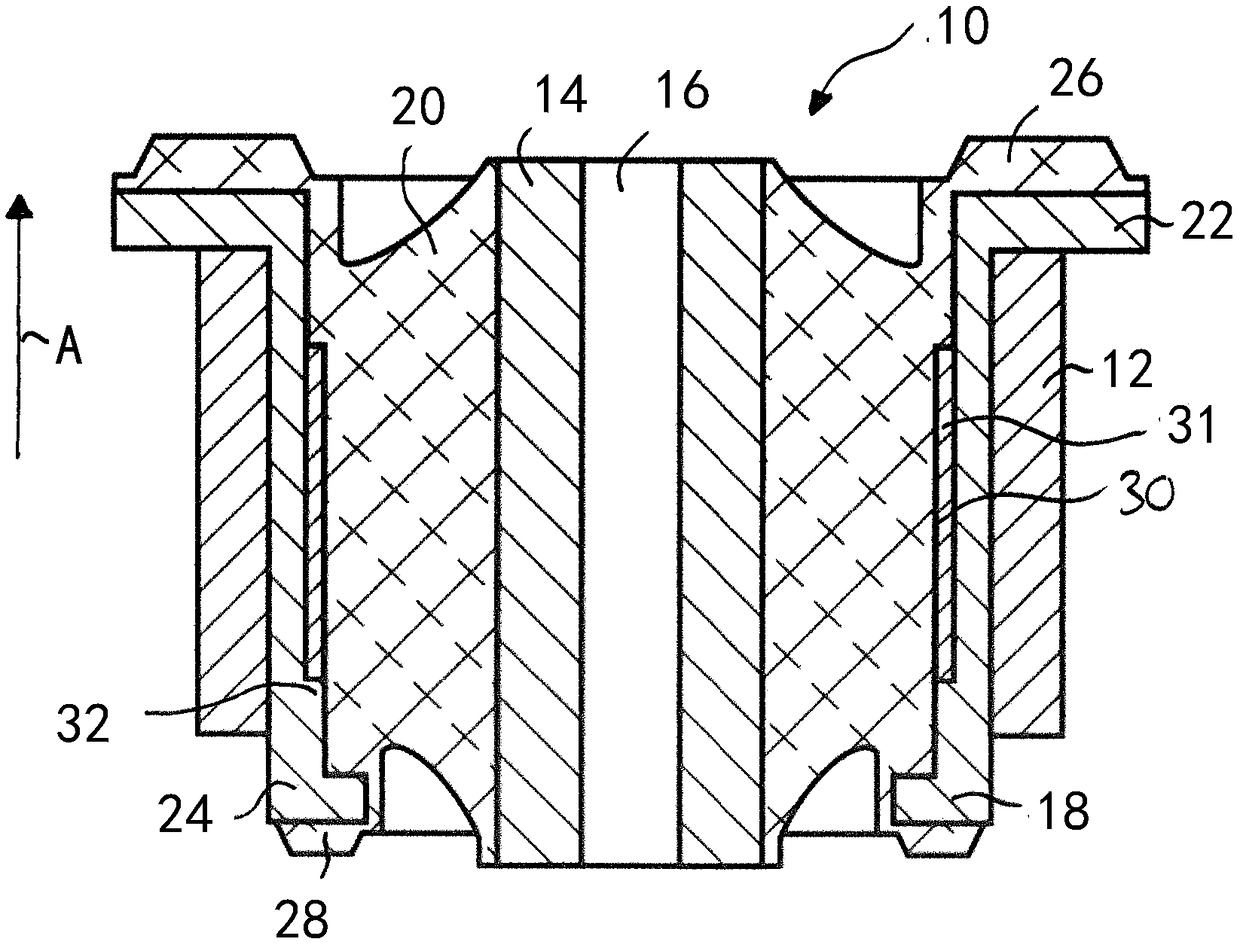

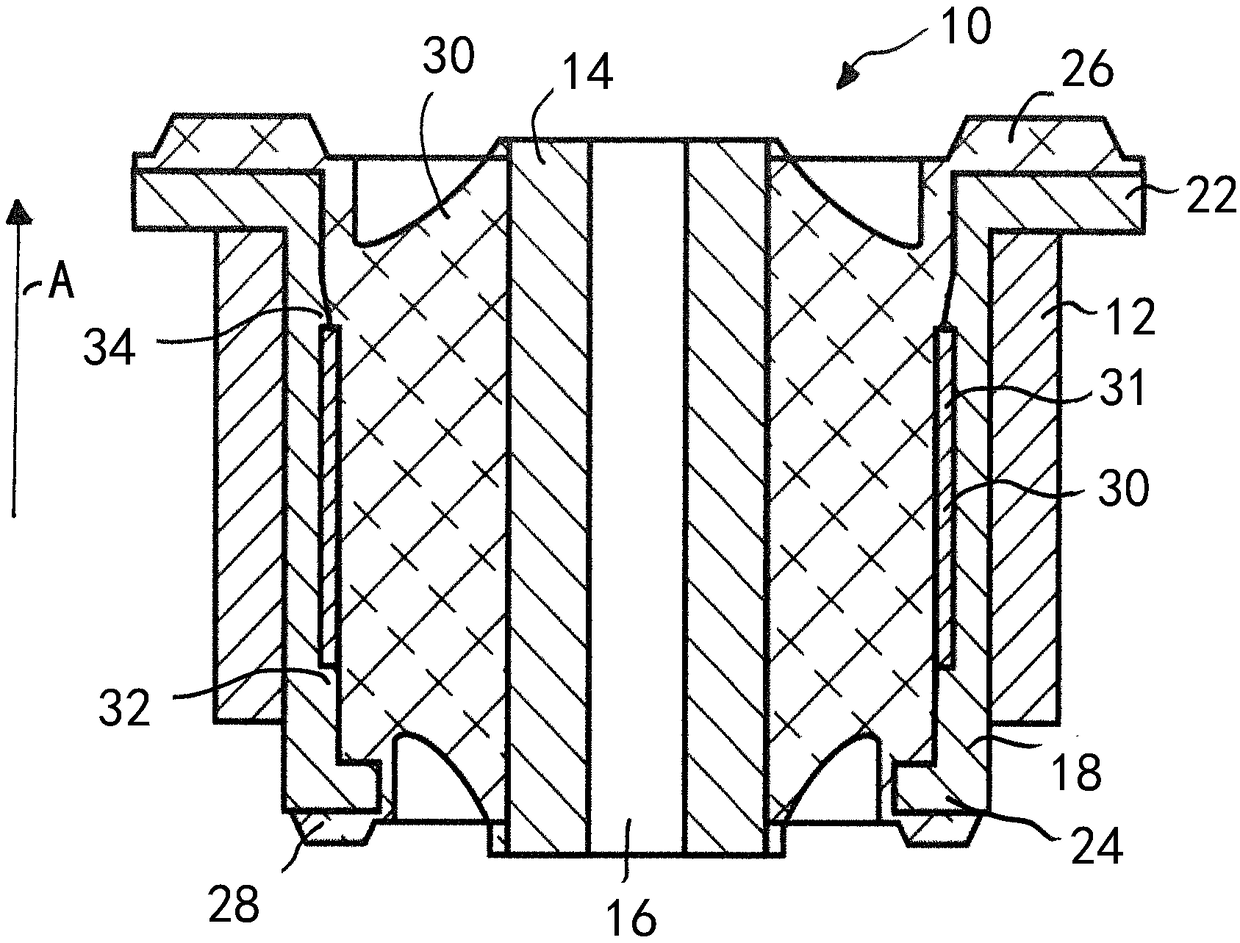

[0040] figure 1 Shown is a bearing bushing 10 which is pressed into a receiving hole 12 of a motor vehicle chassis (not shown). The bushing 10 has an inner core 14 with a central hole 16 for connecting the bearing bushing 10 to a motor vehicle component not shown, an outer sleeve 18 surrounding the inner core 14 and connecting the inner core 14 and outer sleeve 18 interconnected elastomer 20 .

[0041] The outer sleeve 18 is made of plastic or fibre-reinforced plastic and has at a first end a radially outwardly pointed first flange portion 22 and a radially inwardly pointed second flange portion 24, the first flange portion 22 adjoining to receive end of hole 12.

[0042] The elastomer 20 is integrally connected to the outer sleeve 18, in particular by vulcanization, and has a first axial stop 26 in the area of the first flange part 22 and a second axial stop 26 in the area of the second flange part 24. Axial stop 28 .

[0043] as well figure 1 As shown, the support 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com