Three-dimensional liquid in-situ SERS detection substrate and preparation method and application thereof

A liquid, in-situ technology, applied in the field of SERS substrates, can solve problems such as poor repeatability, low sensitivity of detection signals, and difficulty in sufficient contact, and achieve the effects of high repetition rate, enhanced interaction, and enhanced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

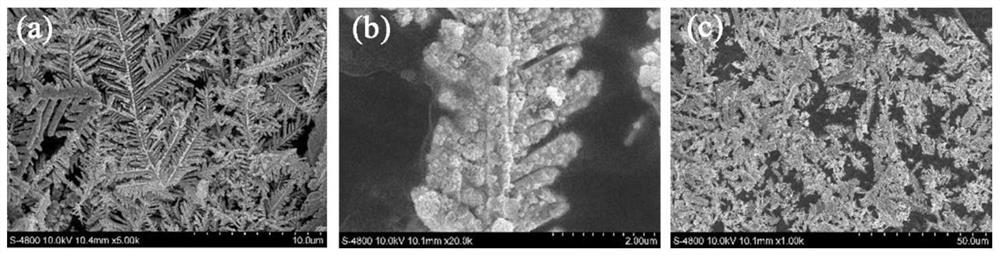

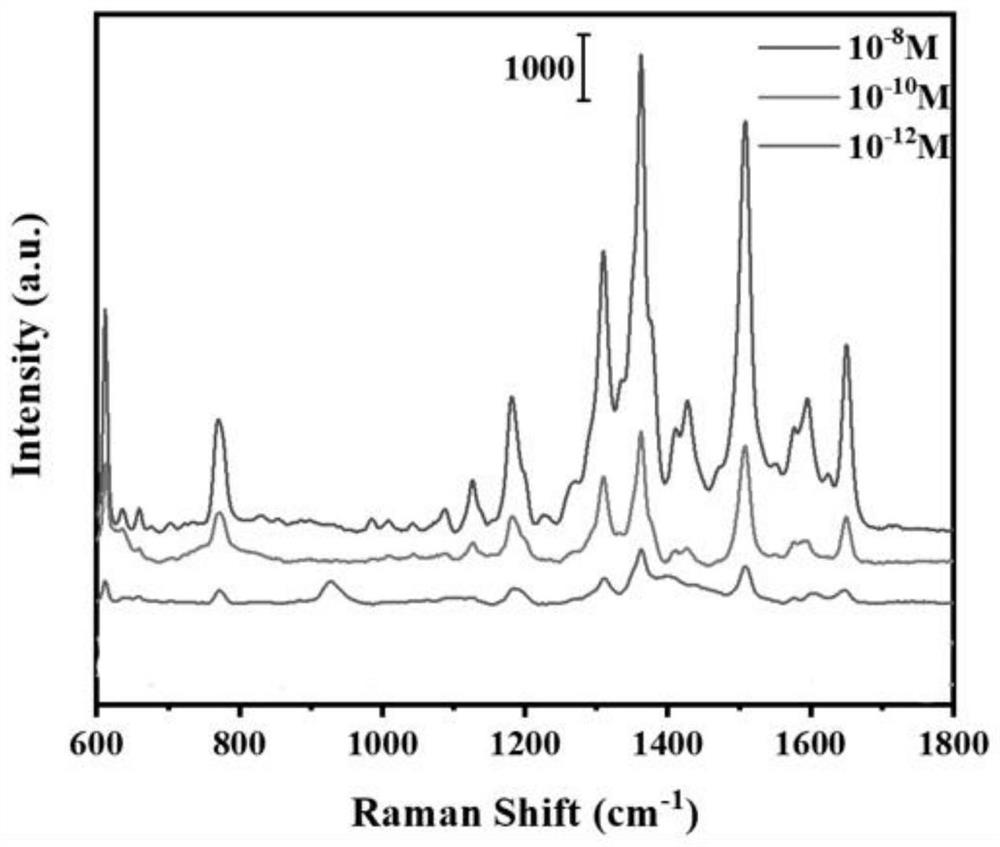

[0030] A three-dimensional liquid in-situ SERS detection substrate. In a channel tube encapsulated with a metal wire, a dendritic gold-silver composite multi-level structure that runs through the metal wire and the channel tube is prepared through a displacement reaction to form a three-dimensional liquid in-situ SERS detection. base.

[0031] A method for preparing the above-mentioned three-dimensional liquid in-situ SERS detection substrate, comprising the following steps:

[0032] Step 1, pretreat the capillary glass tube: place the capillary glass tube in piranha solution, soak it for 12 hours, wash it with ultrapure water, and dry it at room temperature for later use;

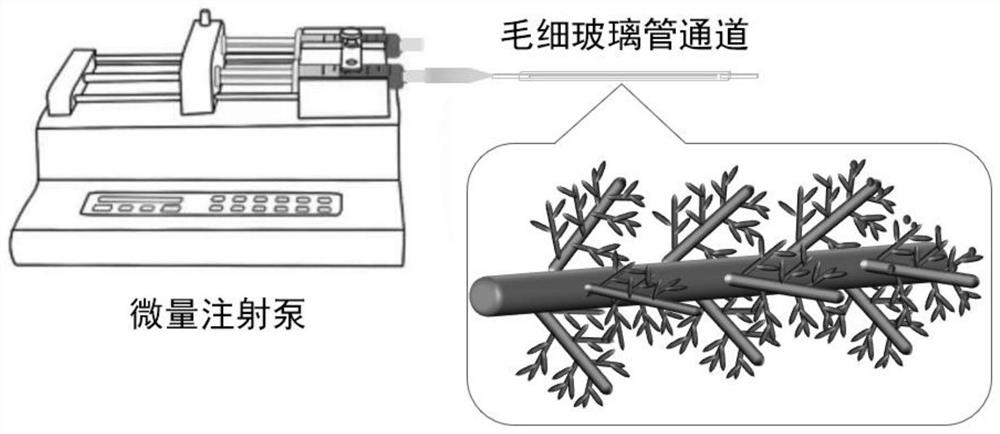

[0033] Step 2, place the wire in ethanol for ultrasonic cleaning for 10 minutes, and then wash it with ultrapure water, as figure 1 As shown, insert into the capillary glass tube, both ends of the capillary glass tube are sealed, and only the liquid flow channel is left. The inherent electrochemical pote...

Embodiment 2

[0043]A method for preparing a three-dimensional liquid in-situ SERS detection substrate, the specific steps are as follows:

[0044] At room temperature, dissolve 0.85g of silver nitrate powder and 0.1g of chloroauric acid in 50mL of ultrapure water, stir magnetically at 2000rpm for 5min, and prepare a silver nitrate solution with a concentration of 0.1mol / L and 0.005mol / L of chloroauric acid. Solution, keep away from light for later use. Three pure copper wires with a length of 50 mm and a diameter of 0.05 mm were ultrasonically cleaned and dried for later use. Set up the reaction channel, inject the silver nitrate solution, set the flow rate of the syringe pump to 0.2mL / min, and react for 15min. Subsequently, the chloroauric acid solution was continuously injected through the syringe pump, the flow rate of the syringe pump was 0.1 mL / min, and the reaction time was 30 min. After the reaction, adjust the speed of the syringe pump to 2 mL / min, inject 30 mL of ultrapure water...

Embodiment 3

[0046] A method for preparing a three-dimensional liquid in-situ SERS detection substrate, the specific steps are as follows:

[0047] At room temperature, dissolve 0.85g of silver nitrate powder and 0.1g of chloroauric acid in 50mL of ultrapure water, stir magnetically at 2000rpm for 5min, and prepare a silver nitrate solution with a concentration of 0.1mol / L and 0.005mol / L of chloroauric acid. Solution, keep away from light for later use. Five pure copper wires with a length of 50 mm and a diameter of 0.05 mm were ultrasonically cleaned, and dried for later use. Set up the reaction channel, inject the silver nitrate solution, set the flow rate of the syringe pump to 0.2mL / min, and react for 15min. Subsequently, the chloroauric acid solution was continuously injected through the syringe pump, the flow rate of the syringe pump was 0.1 mL / min, and the reaction time was 30 min. After the reaction, adjust the speed of the syringe pump to 2 mL / min, inject 30 mL of ultrapure wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com