Reinforced polyamide composition with high laser transmittance and low water absorption and its preparation method and application

A technology of polyamide composition and transmittance, which is applied in the field of polymers, can solve the problems of reducing the mechanical properties of materials, and achieve the effects of excellent mechanical properties, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

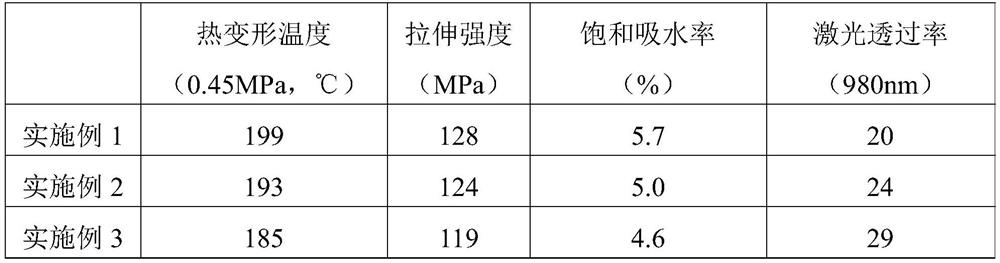

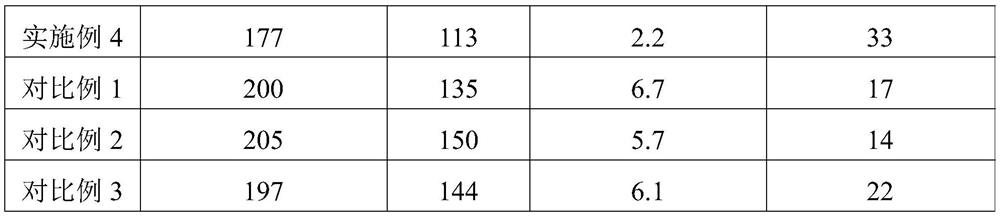

Examples

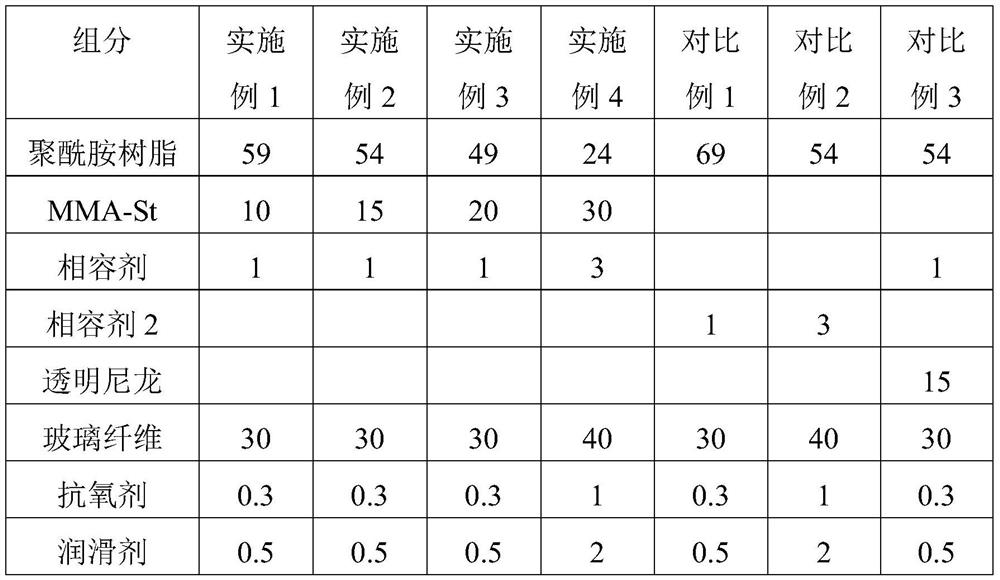

Embodiment 1

[0032] A reinforced polyamide composition with high laser transmittance and low water absorption performance and a preparation method thereof, the composition comprises the following components and steps:

[0033] (1) Prepare materials according to the following components and parts by weight:

[0034] Polyamide resin (select PA6 CM1017 from Toray Company, Japan) 59;

[0035] Styrene-methyl methacrylate copolymer (the content of methyl methacrylate is about 60%) 10;

[0036] Compatibilizer PS-g-GMA (commercially available) 1;

[0037] Glass fiber (select ECS 301HP, Chongqing glass fiber) 30;

[0038] Antioxidant (select Irganox 1098 from Ciba) 0.3;

[0039] Lubricant (select commercially available ethylene bis-stearic acid amide) 0.5;

[0040](2) Mix the above-mentioned raw materials, except glass fiber, into the high-speed mixer according to the above proportions and stir, after mixing evenly, add the twin-screw extruder through the metering device, add the glass fiber fr...

Embodiment 2

[0042] A reinforced polyamide composition with high laser transmittance and low water absorption performance and a preparation method thereof, the composition comprises the following components and steps:

[0043] (1) Prepare materials according to the following components and parts by weight:

[0044] Polyamide resin (select PA6 CM1017 from Toray Company, Japan) 54;

[0045] Styrene-methyl methacrylate copolymer (wherein the content of methyl methacrylate is about 60%) 15;

[0046] Compatibilizer PS-g-GMA (commercially available) 1;

[0047] Glass fiber (select ECS 301HP, Chongqing glass fiber) 30;

[0048] Antioxidant (select Irganox 1098 from Ciba) 0.3;

[0049] Lubricant (for use commercially available ethylene bis-stearic acid amide) 0.5;

[0050] (2) Mix the above-mentioned raw materials, except glass fiber, into the high-speed mixer according to the above proportions and stir, after mixing evenly, add the twin-screw extruder through the metering device, add the glas...

Embodiment 3

[0052] A reinforced polyamide composition with high laser transmittance and low water absorption performance and a preparation method thereof, the composition comprises the following components and steps:

[0053] (1) Prepare materials according to the following components and parts by weight:

[0054] Polyamide resin (selected PA6 CM1017 of Japan Toray Company) 49;

[0055] Styrene-methyl methacrylate copolymer (wherein the content of methyl methacrylate is about 60%) 20;

[0056] Compatibilizer PS-g-GMA (commercially available) 1;

[0057] Glass fiber (select ECS 301HP, Chongqing glass fiber) 30;

[0058] Antioxidant (select Irganox 1098 from Ciba) 0.3;

[0059] Lubricant (for use commercially available ethylene bis-stearic acid amide) 0.5;

[0060] (2) Mix the above-mentioned raw materials, except glass fiber, into the high-speed mixer according to the above proportions and stir, after mixing evenly, add the twin-screw extruder through the metering device, add the glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com