Composite molded article

A technology of composite molding and resin molding, applied in the field of laser welding molded products, to achieve the effects of excellent color tone and thermal stability, high flame retardancy, and excellent laser transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~19 and comparative example 1~12

[0175] (1) Preparation of pellets

[0176] According to the ratio shown in Tables 1 to 3, each component [bromine compound (B), antimony oxide (C) and / or polycarbonate resin (D), phosphorus compound (E), crystal nucleating agent (F )] was blended with the polyester-based resin (A) shown in Tables 1 to 3, and uniformly mixed with a V-type blender. Using a 30mmφ twin-screw extruder, melt-mix the obtained mixture with the filler (G) and fluorine-containing resin (H) in the proportions shown in Table 1 at a barrel temperature of 260°C, and cool the strands ejected from the die. Cut to obtain pellets. In addition, the pellets contained 0.3 parts by weight of a phenolic antioxidant (manufactured by Chiba Co., Ltd., "Irganox 1010") and 0.5 parts by weight of a release agent (manufactured by Clariant Co., Ltd., "Wax E").

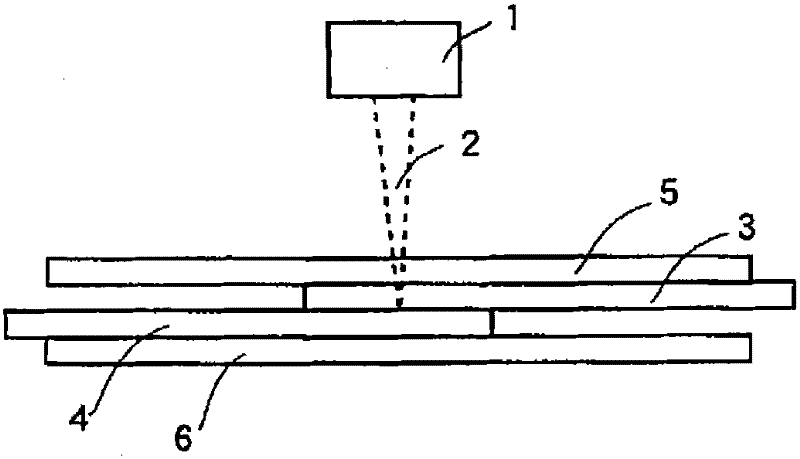

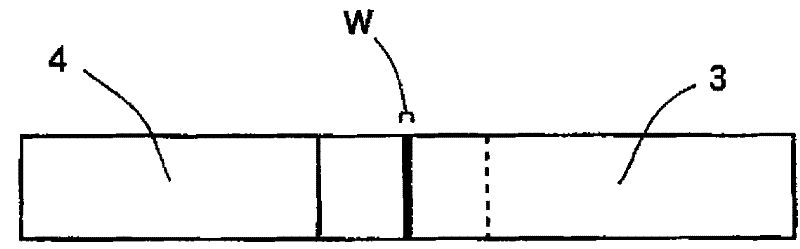

[0177] (2) Manufacturing and laser welding of molded products

[0178] Using the pellets obtained in (1) above, resin molded product A (length 8 cm x width 1 cm x ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com