High-density cross-scale solid solution ceramic reinforced aluminum-based composite material and preparation method thereof

A composite material and reinforced aluminum-based technology, which is applied in the direction of additive processing, additive manufacturing, and energy efficiency improvement, can solve the problems of easy agglomeration, limited addition of reinforcement phase, and difficulty in nano-particles, so as to improve mechanical properties, Uniform distribution of ceramic reinforcement phase, the effect of improving the forming quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

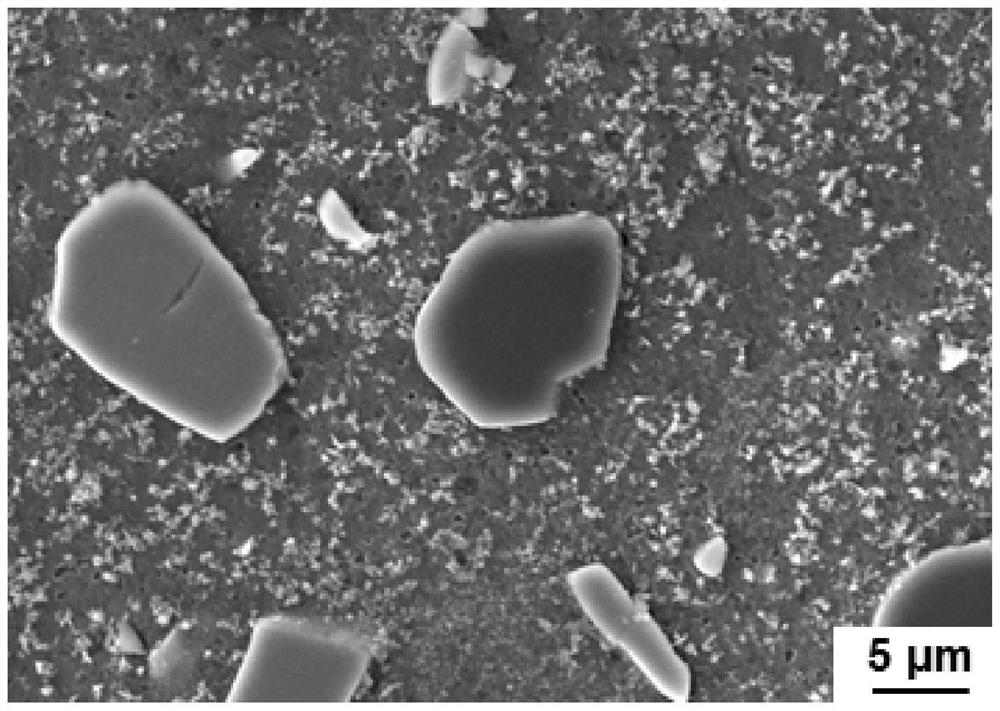

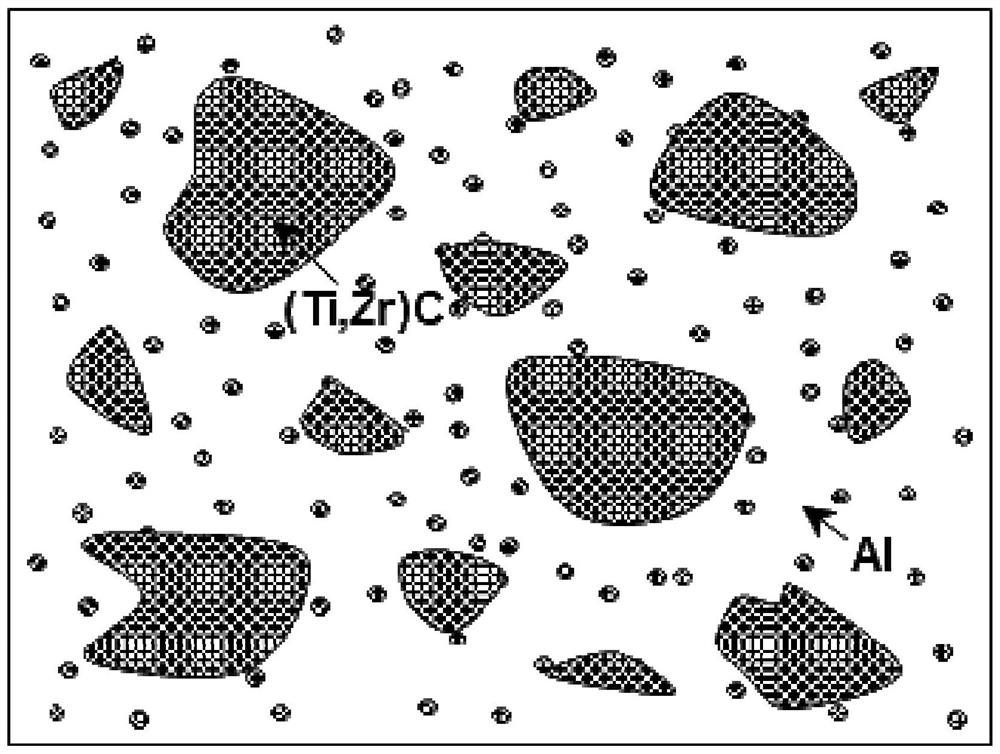

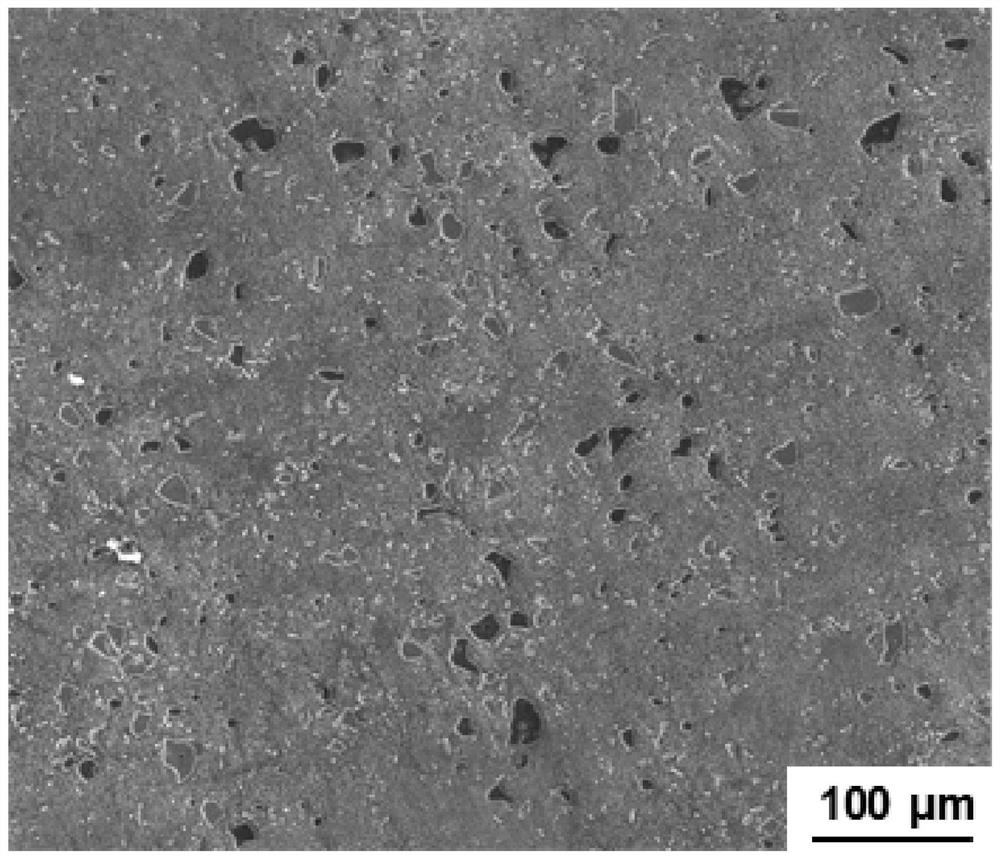

[0035] (1) Mix ZrC ceramic powder and TiC ceramic powder with pure Al powder according to the ratio of 3:2 each, the mass of ceramic powder accounts for 20% of the total mass of composite powder, and ball mill the mixed powder to prepare cross-scale (Ti, Zr) C reinforced aluminum base composite powder. Use QM series planetary ball mill to carry out ball milling and powder mixing operation. This process uses ceramic pots, and the ball milling medium is ceramic balls with diameters of 6mm, 8mm and 10mm. The parameters of the ball milling process are set as follows: the ball-to-material ratio is 2:1, the ball milling speed is 200rpm, and the ball milling time is 4h. At the same time, to prevent the temperature in the ball mill tank from being too high due to the continuous ball milling time being too long, the equipment operation mode during ball milling adopts a one-way interval operation mode, that is, it runs for 15 minutes and stands still for 5 minutes. The ball milling pro...

Embodiment 2

[0043] (1) Mix ZrC ceramic powder and TiC ceramic powder with pure aluminum metal powder in a ratio of 3:2 each, the mass of ceramic powder accounts for 15% of the total mass of the composite powder, and ball mill the mixed powder to prepare cross-scale (Ti, Zr)C reinforcement Aluminum matrix composite powder. Use QM series planetary ball mill to carry out ball milling and powder mixing operation. This process uses ceramic pots, and the ball milling medium is ceramic balls with diameters of 6mm, 8mm and 10mm. The parameters of the ball milling process are set as follows: the ball-to-material ratio is 2:1, the ball milling speed is 150rpm, and the ball milling time is 5h. At the same time, to prevent the temperature in the ball mill tank from being too high due to the continuous ball milling time being too long, the equipment operation mode during ball milling adopts a one-way interval operation mode, that is, it runs for 15 minutes and stands still for 5 minutes. The ball mil...

Embodiment 3

[0051] (1) Mix ZrC ceramic powder and TiC ceramic powder with Al-Mg alloy powder according to the ratio of 3:2 each. The mass of ceramic powder accounts for 10% of the total mass of the composite powder, and the mixed powder is ball milled to prepare cross-scale (Ti, Zr)C Reinforced aluminum matrix composite powder. Use QM series planetary ball mill to carry out ball milling and powder mixing operation. This process uses ceramic pots, and the ball milling medium is ceramic balls with diameters of 6mm, 8mm and 10mm. The parameters of the ball milling process are set as follows: the ball-to-material ratio is 2:1, the ball milling speed is 250rpm, and the ball milling time is 3h. At the same time, to prevent the temperature in the ball mill tank from being too high due to the continuous ball milling time being too long, the equipment operation mode during ball milling adopts a one-way interval operation mode, that is, it runs for 15 minutes and stands still for 5 minutes. The ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com