Aluminum alloy composite material for 3D printing, 3D printing product and preparation method thereof

A technology of 3D printing and composite materials, which is applied in the field of aluminum alloy composite materials for 3D printing, 3D printing products and their preparation, can solve the problems of complex composition, large difference in linear expansion coefficient and solidification temperature, etc., and achieve increased nucleation rate, Improved laser absorption rate and enhanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

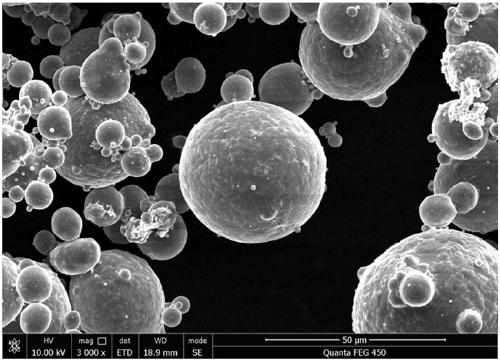

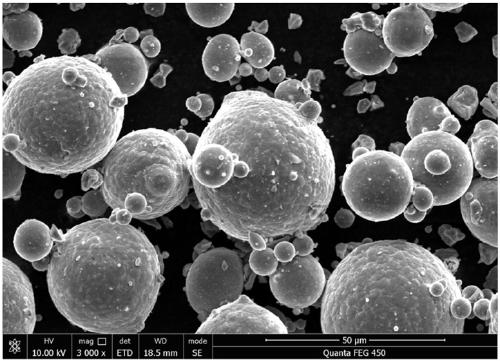

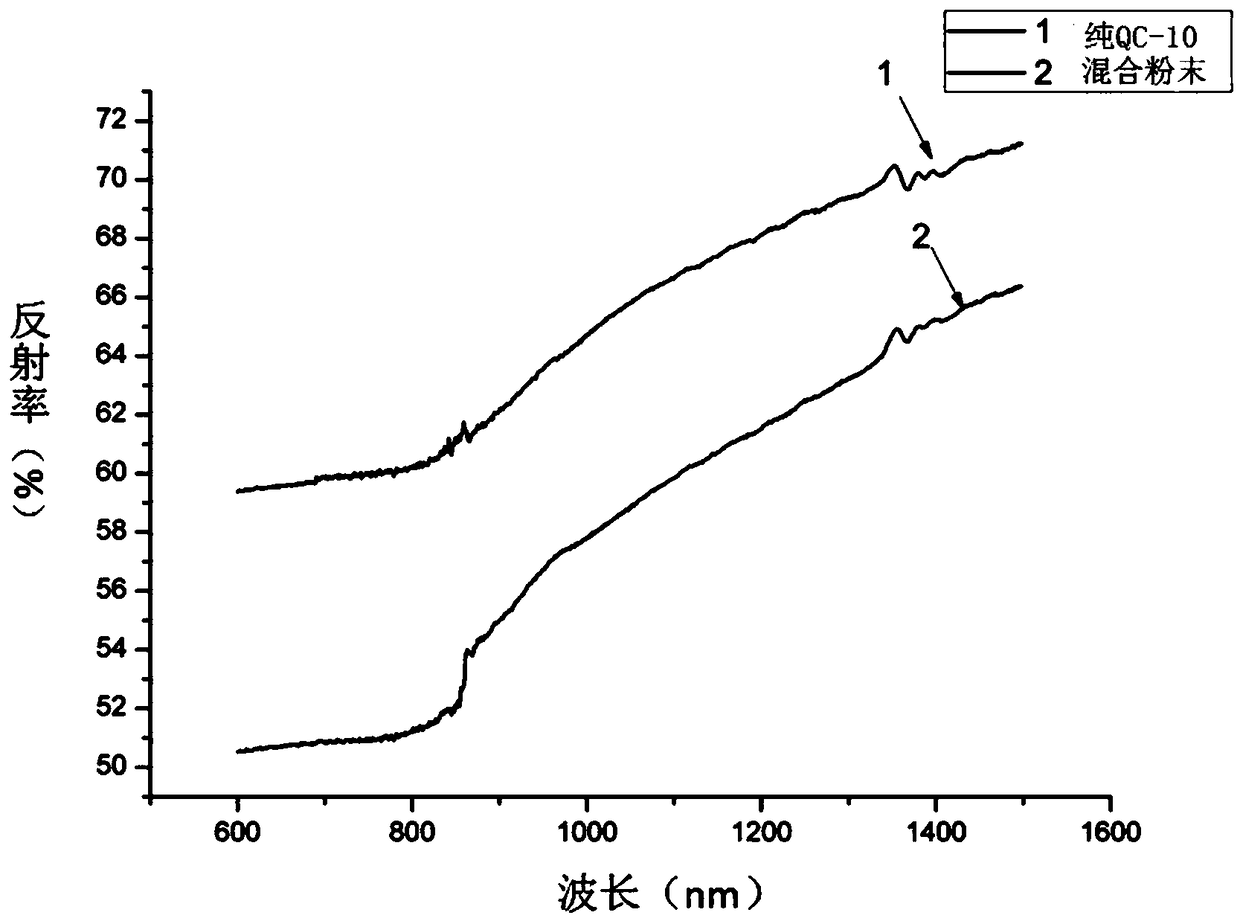

[0036] Use a sieving machine equipped with a 325-mesh screen to sieve the QC-10 aluminum alloy powder to obtain a fine powder below 61 μm; put the raw material QC-10 aluminum alloy powder in a vacuum drying oven and dry it under vacuum at 60°C After more than 3 hours, the dried QC-10 aluminum alloy powder was obtained; through a high-precision electronic scale, 4wt% Si element powder and 2wt% TiB were added to the dried QC-10 aluminum alloy powder 2 Powder, the average particle size of Si element powder is 70μm, TiB 2 The average particle size of the powder is 5 μm; the obtained powder is mechanically mixed by a mechanical powder mixer, and the mixing time is 45 minutes to obtain a mixed powder; finally, the mixed powder is dried again in a vacuum drying oven to obtain a dried mixed powder , which is an aluminum alloy composite material for 3D printing.

[0037] Performance analysis and testing of the aluminum alloy composite materials for 3D printing obtained above, includin...

Embodiment 2

[0048] In laser 3D printing, each final part is formed by melting layer by layer. The laser reaches the powder layer with a certain energy density to melt the powder. Every time a layer is melted, the platform descends, and the new powder is covered with this layer. layer, and then repeat the above process to finally prepare the desired part. Therefore, the forming quality is closely related to many setting parameters. When the parameters are inappropriate, the formed parts are prone to unmelted or overburned states, the bonding between layers is not tight enough, the phenomenon of spheroidization is serious, and the pores increase, etc., which are not conducive to forming. This means that processing parameters are extremely important to the laser 3D forming process and directly affect various properties of the formed part.

[0049] Using the aluminum alloy composite material for 3D printing prepared in Example 1 above, laser 3D printing was performed using a model EOS M290 m...

Embodiment 3

[0052] The preparation method of this embodiment is basically the same as that of the 3D printed product in Example 2. The difference between the two is that the printed product of this embodiment has undergone primary aging heat treatment, specifically, before the surface of the formed part is frosted, The molded parts were heat treated at 120 °C for 18 h in a heating furnace. Other preparation process is identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com