Fully-degradable bio-based composite material product and preparation method thereof

A composite material and bio-based technology, applied in the field of biodegradable materials processing, can solve the problems of low load-bearing capacity of biodegradable materials, high processing cost of biodegradable plastic raw materials, low transparency, etc., to achieve complete biodegradation effect, printing Excellent appearance and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

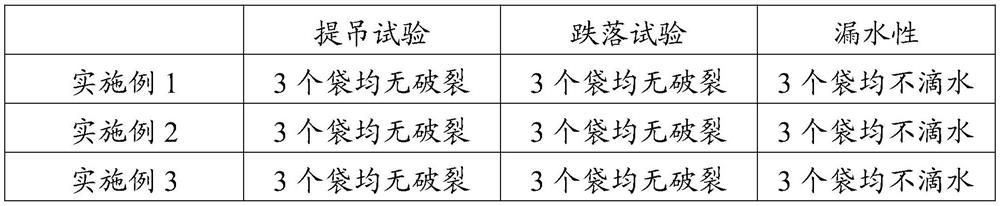

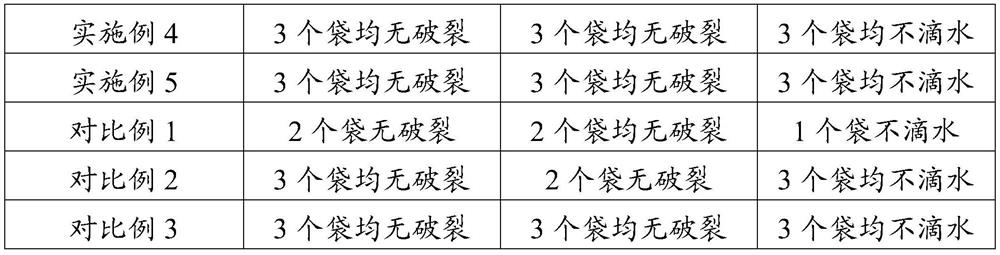

Examples

Embodiment 1

[0044] A fully degradable bio-based composite material product is composed of the following raw materials in parts by weight:

[0045] 40 parts of biomass (including 25 parts of rice husk, 5 parts of straw, 5 parts of corn cob, 5 parts of micronized soybean meal), 10 parts of p-dioxanone polymer, 50 parts of PBTA resin, 30 parts of polylactic acid, compound additive 10 parts of container, 2 parts of lubricant, 1 part of plasticizer. Among them, the composite compatibilizer is composed of coupling agent, mineral oil, and surfactant in a mass ratio of 3:11:9; the lubricant is composed of polyethylene wax, silicone oil, and boron nitride in a mass ratio of 1:1 :1 mixed. The plasticizer is formed by mixing triacetin, polyethylene glycol, polypropylene glycol, and mannitol monoacetate in a mass ratio of 1:5:3:7.

[0046] The preparation method of the fully degradable bio-based composite product of the present invention comprises the following steps:

[0047] S1. Weigh the biomas...

Embodiment 2

[0053] A fully degradable bio-based composite material product is composed of the following raw materials in parts by weight:

[0054] 45 parts of biomass (including 5 parts of coffee shell powder, 35 parts of coconut shell powder, and 5 parts of straw), 15 parts of p-dioxanone polymer, 70 parts of PBTA resin, 35 parts of polylactic acid, and 5 parts of composite compatibilizer , 1.5 parts of lubricant, 0.8 parts of plasticizer. Among them, the composite compatibilizer is made by mixing coupling agent, mineral oil and surfactant in a mass ratio of 2:5:9; the lubricant is a mixture of polyethylene wax and silicone oil in a mass ratio of 1:1; The plasticizer is formed by mixing polyethylene glycol and sorbitol acetate at a mass ratio of 1:2.

[0055] The preparation method of the fully degradable bio-based composite material product of the present invention comprises the following steps:

[0056] S1. Weigh the biomass in proportion, and add it into the reactor for heating, the...

Embodiment 3

[0062] A fully degradable bio-based composite material product is composed of the following raw materials in parts by weight:

[0063] 50 parts of biomass (including 20 parts of coconut shell powder and 30 parts of coffee shell powder), 25 parts of p-dioxanone polymer, 65 parts of PBTA resin, 45 parts of polylactic acid, 3 parts of composite compatibilizer, and 2.5 parts of lubricant Parts, 1.5 parts of plasticizer. The composite compatibilizer is formed by mixing coupling agent, mineral oil, and surfactant in a mass ratio of 1:6:3; the lubricant is polyethylene wax, and the plasticizer is glycerol triacetate.

[0064] The preparation method of the fully degradable bio-based composite product of the present invention comprises the following steps:

[0065] S1. Weigh the biomass in proportion, and add it into the reactor for heating, the heating temperature is 100°C, and the heating time is 60min;

[0066] S2. After stopping the heating, add a composite compatibilizer to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com