A kind of high dispersion dispersant for pesticide and preparation method thereof

A high-dispersibility and dispersant technology, applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve problems affecting spraying effects, uneven concentration, environmental pollution, etc., and achieve dispersibility Easy to control, increase adhesion, improve the effect of mutual solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

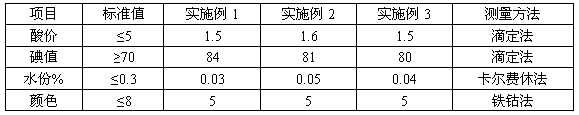

Embodiment 1

[0018] Take 7 kg of methyl oleate, 1.5 kg of ethanol, 1 kg of triethanolamine dodecyl phosphate, and 1.5 kg of Tween-40. Weigh the above components by weight, mix dodecyl phosphate triethanolamine and Tween-40 with ethanol, then add methyl oleate, heat up to 45°C and stir to fully mix, then cool naturally have to.

Embodiment 2

[0020] Take 5 kg of methyl oleate, 0.5 kg of ethanol, 1.5 kg of triethanolamine dodecyl phosphate, and 1 kg of Tween-40. Weigh the above components by weight, mix dodecyl phosphate triethanolamine and Tween-40 with ethanol, then add methyl oleate, heat up to 50°C and stir to fully mix, then cool naturally have to.

Embodiment 3

[0022] Take methyl oleate as 8kg, ethanol as 2kg, dodecyl phosphate triethanolamine as 2kg, and Tween-40 as 3kg. Weigh the above components by weight, mix dodecyl phosphate triethanolamine and Tween-40 with ethanol, then add methyl oleate, heat up to 40°C and stir to fully mix, then cool naturally have to.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com