Removal Process of Heavy Metal Copper from Municipal Sludge

A technology for municipal sludge and heavy metals, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the proportion of inorganic matter in sludge dry sludge filter cake and affecting sludge Resource utilization, reducing heavy metal leaching efficiency and other issues, to achieve the effect of reducing the risk of post-acidification effect, good ecological security, and changing bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

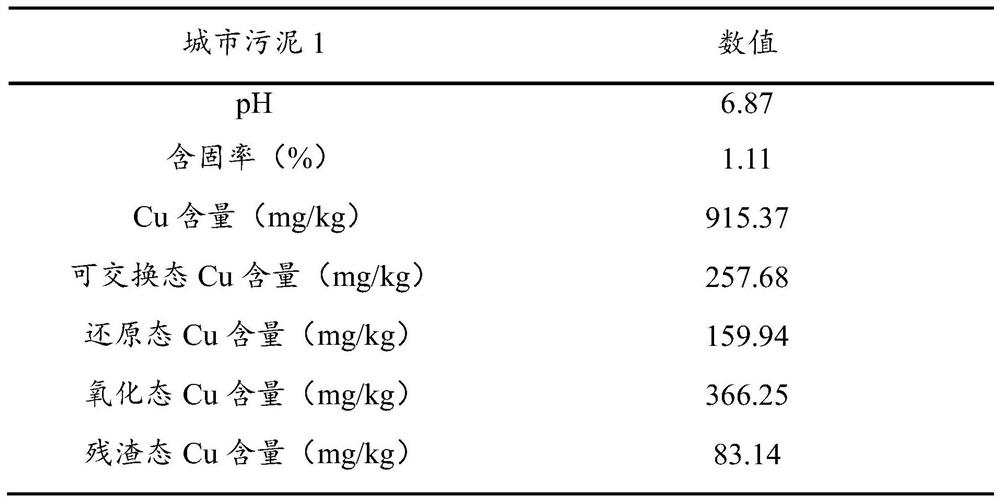

Embodiment 1

[0035] The present embodiment provides the removal process of heavy metal copper in municipal sludge, which comprises the following steps:

[0036] S1) Add sulfur powder 10g, ferrous sulfate 10g and APG-10 0.6g per liter of municipal sludge, add sulfur powder, ferrous sulfate and APG-10 to 150mL municipal sludge, and place in a water bath shaker The first shaking culture of microorganisms was carried out at a constant temperature of 28°C at a speed of 180r / min; when the pH value of the municipal sludge was 2.5, the first shaking culture was ended, and the first culture was obtained;

[0037]S2) add city sludge to described culture for the first time, add sulfur powder 2g, ferrous sulfate 2g and APG-10 0.6g per liter volume in the mixture of city sludge and culture for the first time, add city sewage Sulfur powder, ferrous sulfate and APG-10 were added to the mixture of the mud and the first culture, and placed in a water bath shaker at a speed of 180r / min at a constant tempera...

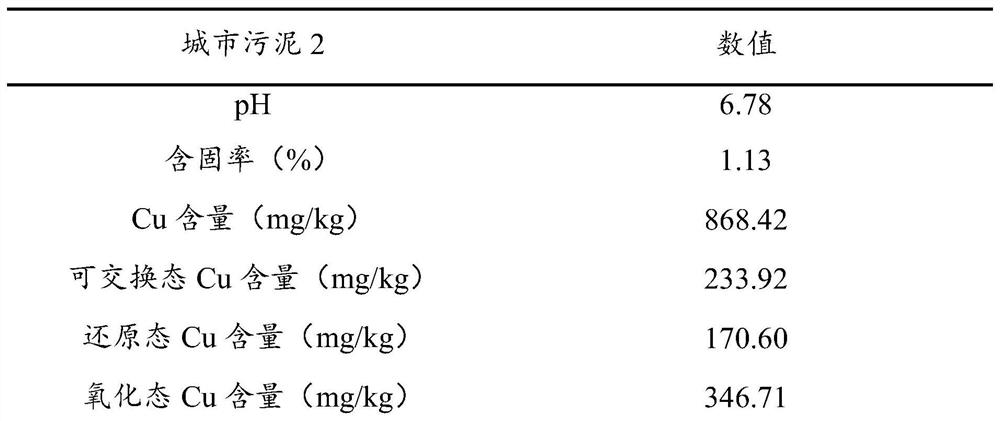

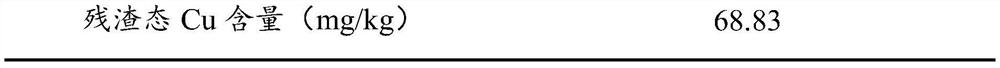

Embodiment 2

[0042] This embodiment provides the removal process of heavy metal copper in municipal sludge, similar to the removal process of Example 1, the difference is:

[0043] 1) In step S1), add sulfur powder 10g, ferrous sulfate 10g and APG-100.6g in every liter of volume municipal sludge, add sulfur powder, ferrous sulfate and APG-10 in 140mL municipal sludge, after that Carry out the first shaking culture of microorganisms;

[0044] 2) In steps S1), S2) and S3), when the pH value of the municipal sludge is 2.6, the shaking culture is ended;

[0045] 3) In steps S1), S2), S3) and S4), the rotation speed of the shaker during shaking culture is 170r / min, and the temperature of shaking culture is 27°C;

[0046] 4) In step S2), the volume ratio of the municipal sludge added in the culture for the first time to the culture for the first time is 6; in step S3), the municipal sludge added in the culture for the second time The volume ratio to the second culture is 6;

[0047] 5) In ste...

Embodiment 3

[0050] This embodiment provides the removal process of heavy metal copper in municipal sludge, similar to the removal process of Example 1, the difference is:

[0051] 1) In step S1), add sulfur powder 10g, ferrous sulfate 10g and APG-100.6g in every liter of volume municipal sludge, add sulfur powder, ferrous sulfate and APG-10 in 160mL municipal sludge, after that Carry out the first shaking culture of microorganisms;

[0052] 2) In steps S1), S2) and S3), when the pH value of the municipal sludge is 2.8, the shaking culture is ended;

[0053] 3) In steps S1), S2), S3) and S4), the rotation speed of the shaker during the shaking culture is 190r / min, and the temperature of the shaking culture is 29°C;

[0054] 4) In step S2), the volume ratio of the municipal sludge added in the culture for the first time to the culture for the first time is 7; in step S3), the municipal sludge added in the culture for the second time The volume ratio to the second culture is 7;

[0055] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com