Deflector, method of manufacturing deflector, and charged particle beam exposure apparatus using deflector

A technology of charged particle beam and manufacturing method, which is applied in the direction of photolithographic exposure device, electric recording process using charge pattern, equipment for electric recording process using charge pattern, etc., which can solve processing line pollution, pollution, and difficult blanking Electrode and other problems, to achieve the effect of solving pollution problems, preventing falling off and deformation, and preventing charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111]

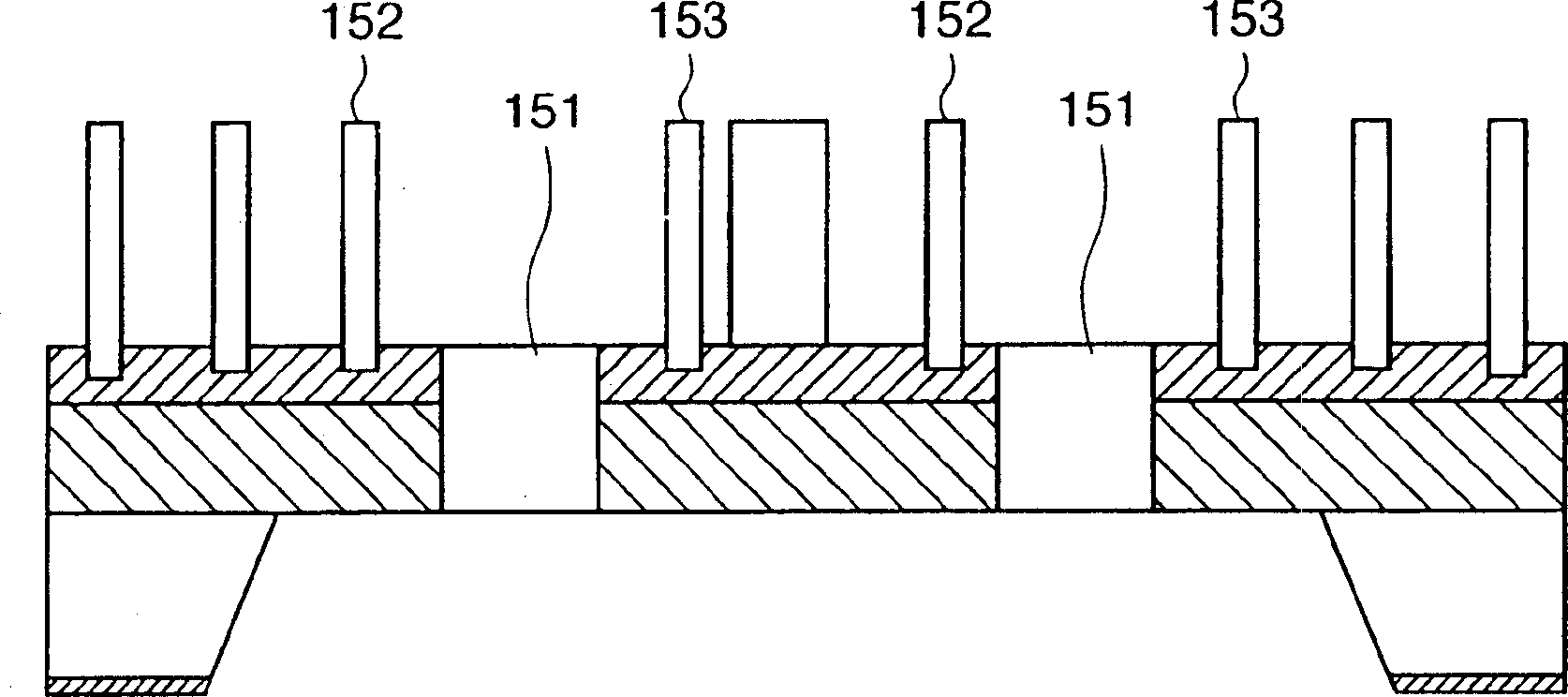

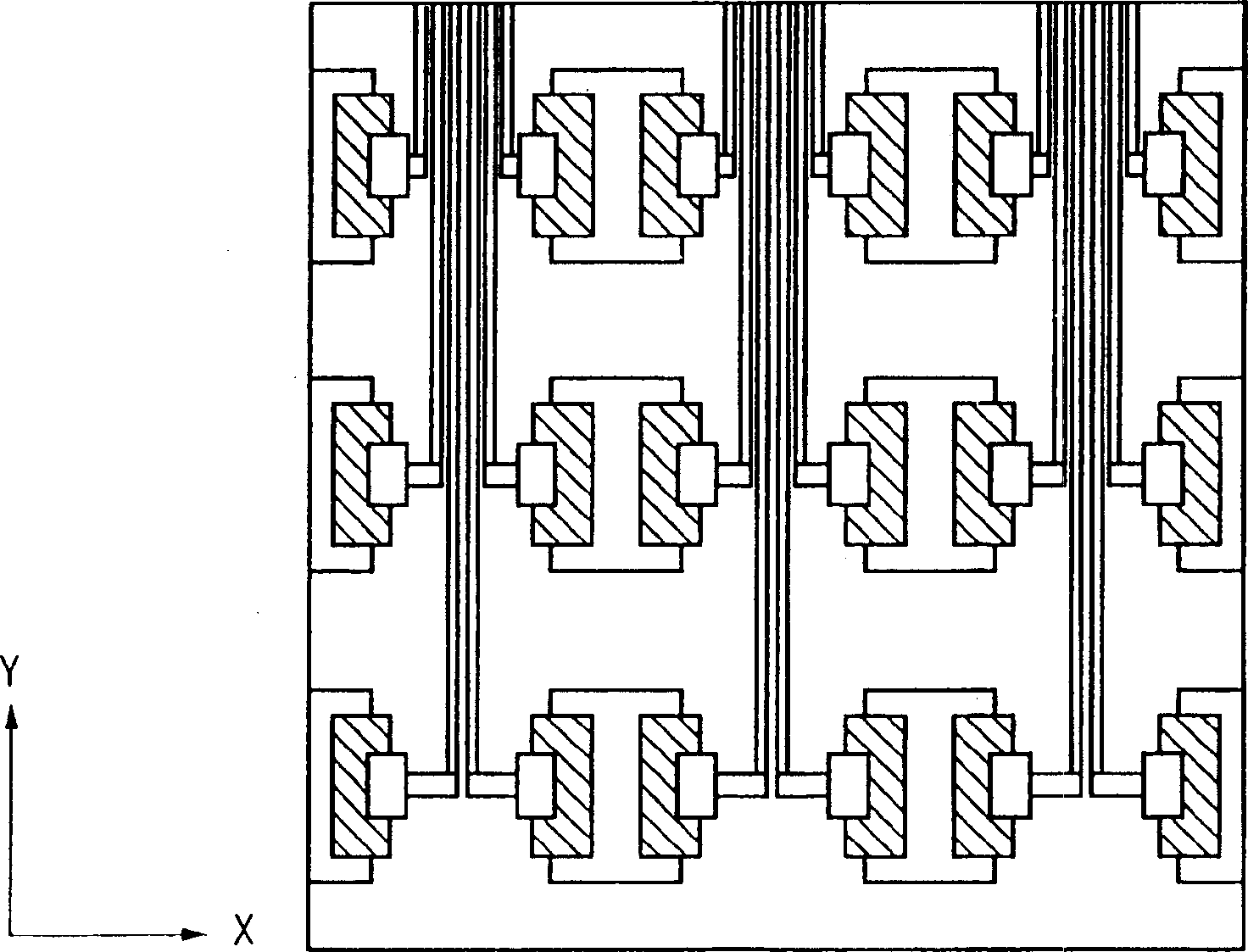

[0112] we refer to Figure 4A ~ Figure 10 A first embodiment of the deflector according to the present invention will be described on the side of the drawing. Figure 4A A plan view showing an electrode substrate 400 configured with blanking electrodes of a 3×3 blanker array, Figure 4B is a view of the electrode substrate 400 viewed from a cross-sectional direction (the insulator for insulating the blanking electrode and the electrode substrate is not shown). exist Figure 4A Among them, 52 and 53 are blanking electrodes, and 51 is an electron beam aperture. Figure 5 It is a plan view of the wiring substrate 500. 52P and 53P represent voltage-applying pads for applying voltage from an external power source (not shown in the figure), and 52' and 53' are for applying voltage from the pads 52P, 53P, and The wirings 52H and 53H of 53P are connection wiring pads for electrically connecting the electrodes 52 and 53 of the electrode substrate 400 . 51' is the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com