Laser stripping material as well as preparation method and application thereof

A technology of laser lift-off and laser irradiation, which is applied in semiconductor/solid-state device manufacturing, adhesive types, polyether adhesives, etc., can solve the problems of unstable dispersion system, poor heat resistance and chemical resistance, and high laser power and other problems, to solve the effects of poor chemical resistance and thermal stability, avoid dispersion instability, and high laser absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

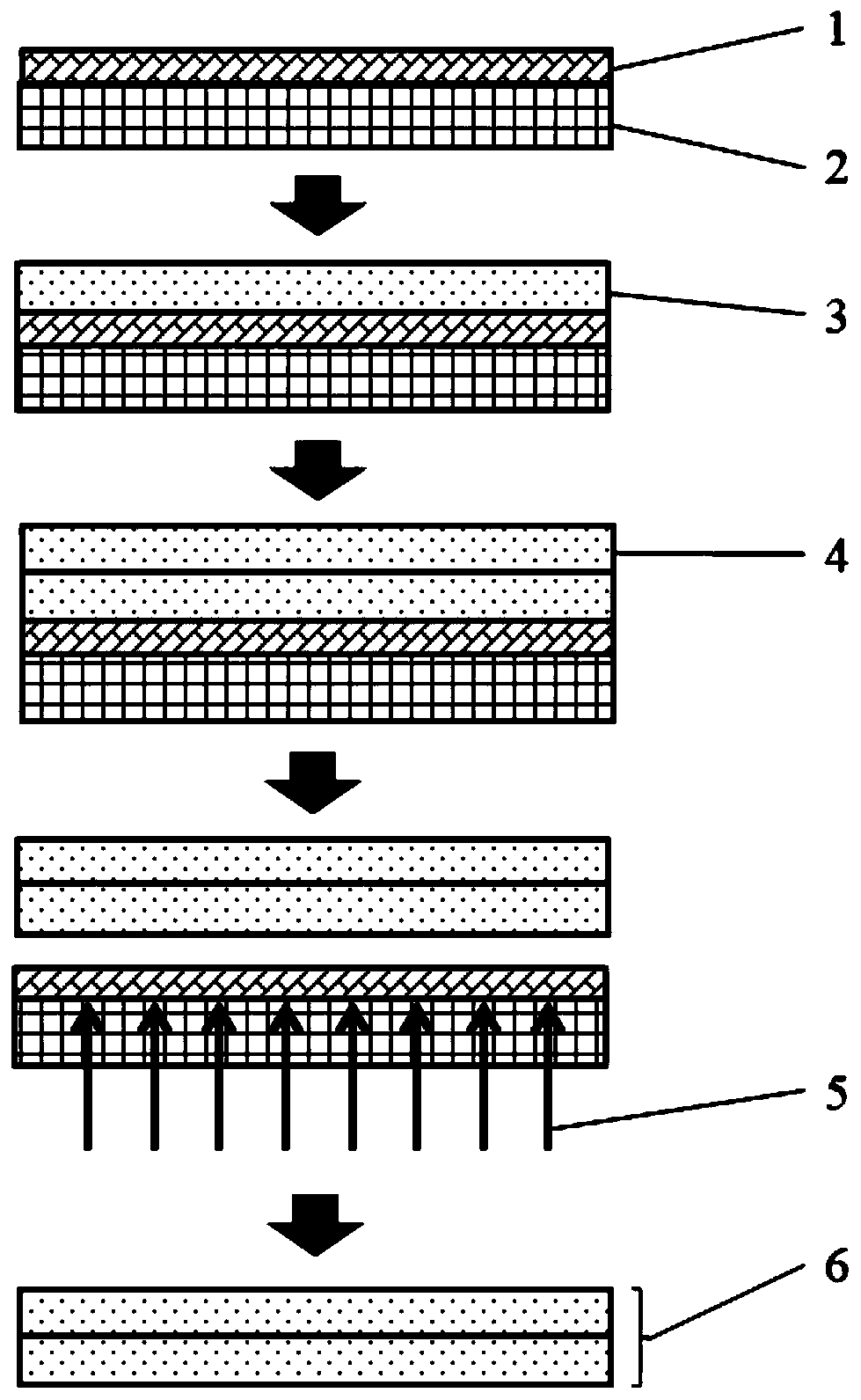

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a laser lift-off material and a preparation method thereof.

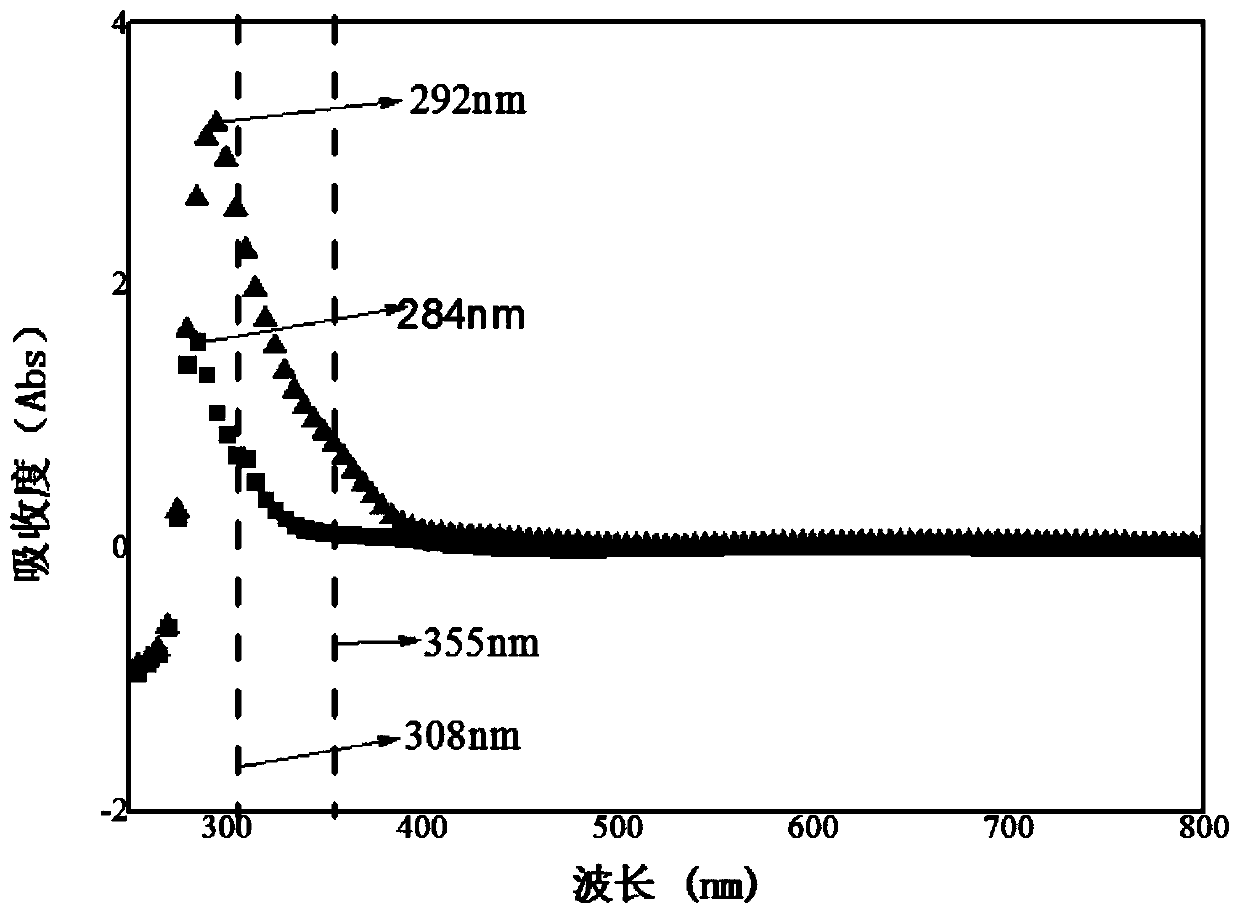

[0051] The laser peeling material includes 20% of polyamic acid, 5% of nano-carbon black light absorbing agent and 75% of N'N-dimethylformamide based on the total mass of 100%.

[0052] Preparation:

[0053] The polyamic acid, nano-carbon black light absorbing agent and N'N-dimethylformamide were mixed at 23° C. for 2 hours at a stirring speed of 200 rpm to obtain the laser lift-off material.

Embodiment 2

[0055] This embodiment provides a laser lift-off material and a preparation method thereof.

[0056] The laser peeling material includes 15% of polyamide, 8% of carbon nanotube light absorbing agent and 77% of N'N-dimethylacetamide based on the total mass of 100%.

[0057] Preparation:

[0058] The polyamide, the carbon nanotube light absorbing agent and N'N-dimethylacetamide were mixed at 25° C. for 2.5 hours at a stirring speed of 300 rpm to obtain the laser lift-off material.

Embodiment 3

[0060] This embodiment provides a laser lift-off material and a preparation method thereof.

[0061] The laser lift-off material includes 10% of polyphenylene sulfide, 4% of graphite powder (light absorbing agent) and 86% of dimethyl sulfoxide, based on the total mass of 100%.

[0062] Preparation:

[0063] The poly(phenylene ether sulfone), graphite powder light absorbing agent and dimethyl sulfoxide were mixed at 30° C. for 3 hours at a stirring speed of 100 rpm to obtain the laser lift-off material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com