7XXX series in-situ aluminum-based composite material powder for laser additive manufacturing and preparation

An aluminum matrix composite material, laser additive technology, applied in the direction of additive processing, etc., can solve the problems of insufficient reliability, high residual stress cracks and holes, material fatigue strength, plasticity and toughness reduction, etc., to expand the application range of materials , Improve the laser absorption rate, inhibit the effect of recrystallization growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

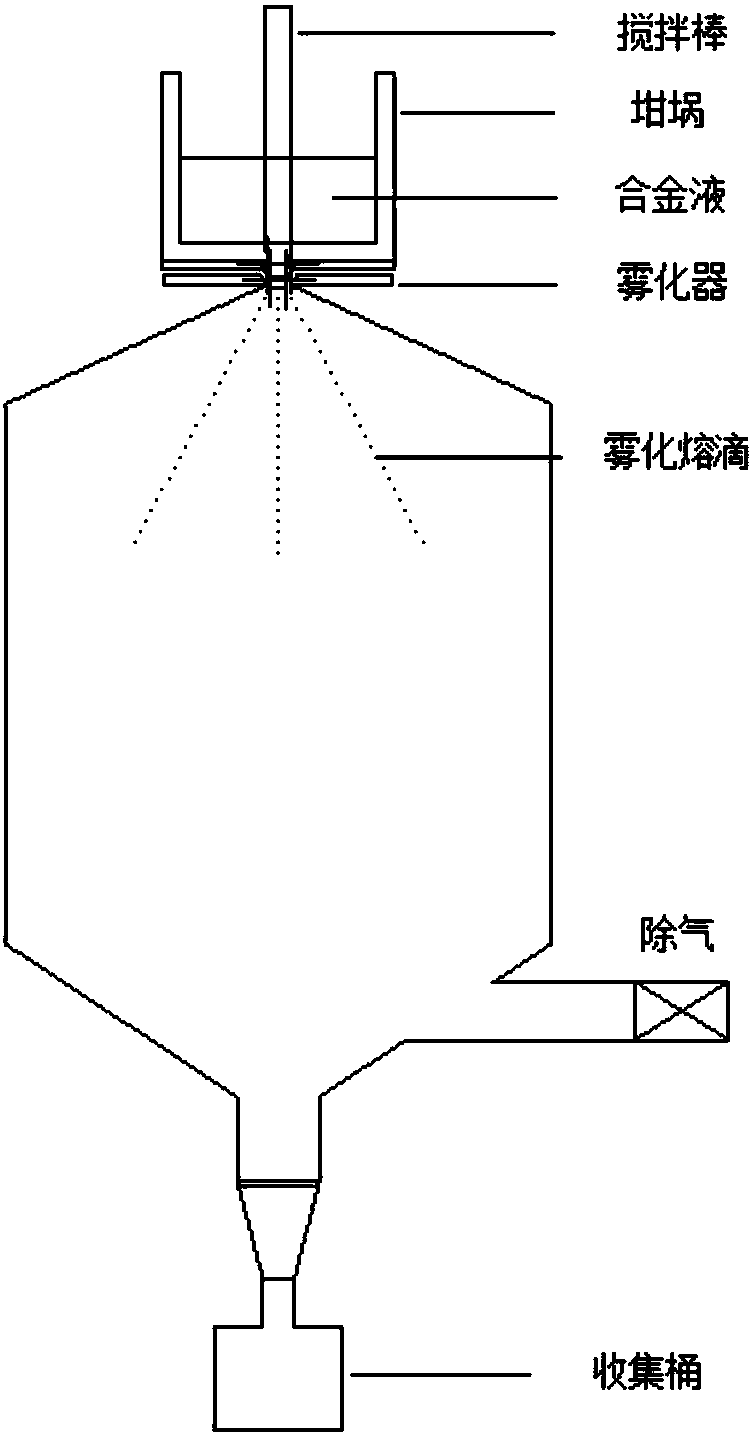

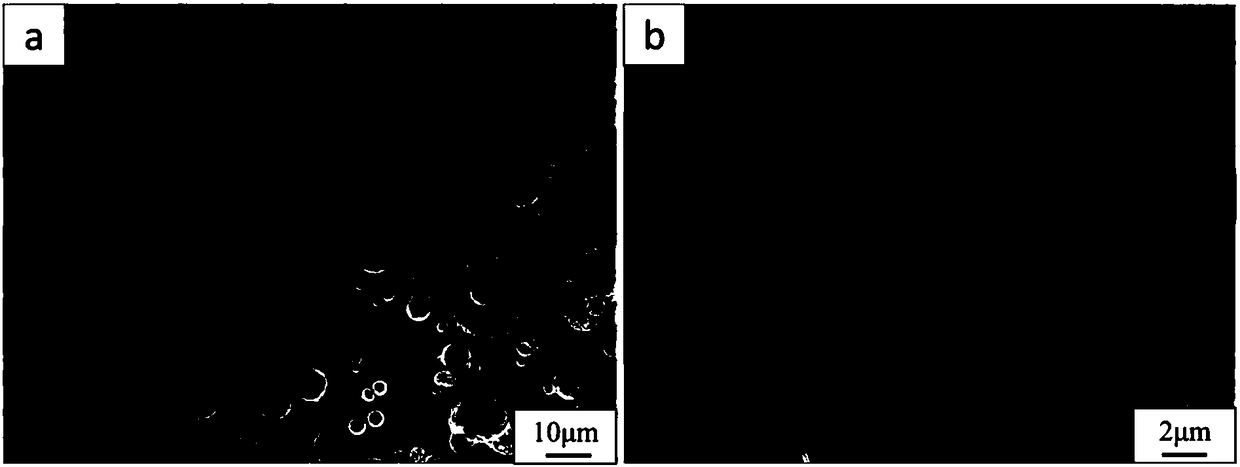

[0043] Experiments were carried out with high-purity Al, industrial pure Mg, industrial pure Zn, Al-50Cu, Al-12Zr master alloy, KBF 4 and K 2 TiF 6 The in-situ self-generated 5wt.%TiB2 reinforced Al-6.7Zn-2.2Mg-2.3Cu-0.1Zr composite was prepared as the raw material. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 After mixing evenly according to the mass ratio of 1:2, add it to the melt after drying; after the reaction is finished, take out the reaction by-products, add Al-50Cu, Al-12Zr master alloy, industrial pure Mg, and industrial pure Zn in sequence, Add JZJ type harmless aluminum alloy refining agent to the body for degassing refining, let stand at 750°C for 15 minutes, and then gas atomize to make powder. Its aerosolization equipment such as figure 1 As shown, the specific process is as follows: the solution temperature is 820°C, He is used for protection and gas atom...

Embodiment 2

[0045] Experiments were carried out with high-purity Al, industrial pure Mg, industrial pure Zn, Al-50Cu, Al-12Zr master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 5wt.%TiB was formulated for the raw material 2 Reinforced Al-6.6Zn-2.2Mg-2.2Cu-0.09Zr composites. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 After mixing evenly according to the mass ratio of 1:2, add it to the melt after drying; after the reaction is finished, take out the reaction by-products, add Al-50Cu, Al-12Zr master alloy, industrial pure Mg, and industrial pure Zn in sequence, Add JZJ type harmless aluminum alloy refining agent to the body for degassing refining, let stand at 750°C for 15 minutes, and then gas atomize to make powder. The gas atomization process is as follows: the solution temperature is 900°C, He is used for protection and gas atomization, the air pressure is 3.10 MPa, and the ...

Embodiment 3

[0047] Experiments were carried out with high-purity Al, industrial pure Mg, industrial pure Zn, Al-50Cu, Al-12Zr master alloy, KBF 4 and K 2 TiF 6 The in-situ self-generated 5wt.%TiB2 reinforced Al-6.6Zn-2.2Mg-2.2Cu-0.09Zr composite was prepared as the raw material. Put high-purity Al into the crucible to melt and heat up to 780°C, and cover it with JZF-03 high-temperature covering agent; put KBF 4 、K 2 TiF 6 After mixing evenly according to the mass ratio of 1:2, add it to the melt after drying; after the reaction is finished, take out the reaction by-products, add Al-50Cu, Al-12Zr master alloy, industrial pure Mg, and industrial pure Zn in sequence, Add JZJ type harmless aluminum alloy refining agent to the body for degassing refining, let stand at 750°C for 15 minutes, and then gas atomize to make powder. The gas atomization process is as follows: the solution temperature is 900°C, Ar protection is used for gas atomization, the air pressure is 1.20 MPa, and the nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com