Aluminum-lithium-matrix composite material powder as well as preparation method and application thereof

A composite material and powder technology, which is applied in the field of lightweight, high-strength, high-modulus nanoparticle-reinforced aluminum-lithium-based composite powder and its preparation, can solve problems such as poor fluidity, high laser reflectivity, and large thermal conductivity, and achieve improved laser performance. Absorption rate, huge application prospect, effect of microstructure refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

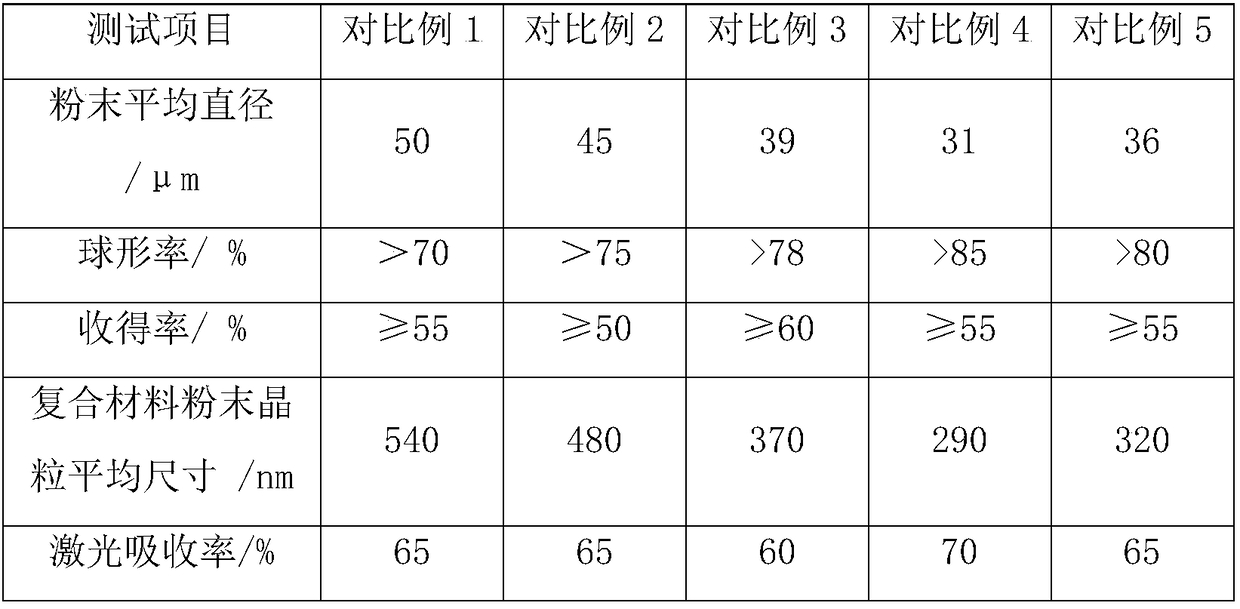

Examples

Embodiment 1

[0032] This embodiment provides an aluminum-lithium-based composite material powder and a preparation method thereof. The specific preparation methods include:

[0033] Pure aluminum, Al-Cu master alloy, Al-Zr master alloy, Al-Sc master alloy, Al-Mg master alloy, pure Li or Al-Li master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 5wt.%TiB 2 Reinforced Al-3Li-1.5Cu-0.2Zr-0.5Mg-0.2Sc-0.1Cd composites. Put the high-purity aluminum ingot into the crucible and melt it, then sprinkle it with JZF-03 high-temperature covering agent; 2 TiF 6 、KBF 4 Mix evenly according to the mass ratio of 2:1, dry and add to the aluminum liquid; after the reaction is complete, remove the reaction by-products, and then add Al-Cu master alloy, Al-12Zr master alloy, Al-Sc master alloy, Al- Mg master alloy, Al-Cd master alloy, add pure Li or Al-Li master alloy under the protection of argon, then add JZJ type harmless aluminum alloy refining agent to the melt for degassing and refining, at 740...

Embodiment 2

[0036] This embodiment provides an aluminum-lithium-based composite material powder and a preparation method thereof. The specific preparation methods include:

[0037] Pure aluminum, Al-Cu master alloy, Al-Zr master alloy, Al-Sc master alloy, Al-Mg master alloy, Al-Cd master alloy, pure Li or Al-Li master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 5wt.%TiB 2 Reinforced Al-3Li-1.5Cu-0.2Zr-0.5Mg-0.2Sc-0.2Cd composites. Put the high-purity aluminum ingot into the crucible and melt it, then sprinkle it with JZF-03 high-temperature covering agent; 2 TiF 6 、KBF 4 Mix evenly according to the mass ratio of 2:1, dry and add to the aluminum liquid; after the reaction is complete, remove the reaction by-products, and then add Al-Cu master alloy, Al-12Zr master alloy, Al-Sc master alloy, Al- Mg master alloy, Al-Cd master alloy, add pure Li or Al-Li master alloy under the protection of argon, then add JZJ type harmless aluminum alloy refining agent to the melt for degassing an...

Embodiment 3

[0040] This embodiment provides an aluminum-lithium-based composite material powder and a preparation method thereof. The specific preparation methods include:

[0041] Pure aluminum, Al-Cu master alloy, Al-Zr master alloy, Al-Sc master alloy, Al-Mg master alloy, Al-Cd master alloy, pure Li or Al-Li master alloy, KBF 4 and K 2 TiF 6 In situ self-generated 10wt.%TiB 2 Reinforced Al-3Li-1.5Cu-0.2Zr-0.4Mg-0.15Sc-0.2Cd composites. Put the high-purity aluminum ingot into the crucible and melt it, then sprinkle it with JZF-03 high-temperature covering agent; 2 TiF 6 、KBF 4 Mix evenly according to the mass ratio of 2:1, dry and add to the aluminum liquid; after the reaction is complete, remove the reaction by-products, and then add Al-Cu master alloy, Al-12Zr master alloy, Al-Sc master alloy, Al- Mg master alloy, Al-Cd master alloy, add pure Li or Al-Li master alloy under the protection of argon, then add JZJ type harmless aluminum alloy refining agent to the melt for degassin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com