Fabrication method of superluminescent diode chip and fabricated light emitting diode chip

A superluminescence and diode technology, applied in diodes, electrical components, circuits, etc., can solve the problems of increased system volume, unfavorable integration, and increased cost, and achieve the effects of high output power, increased output, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

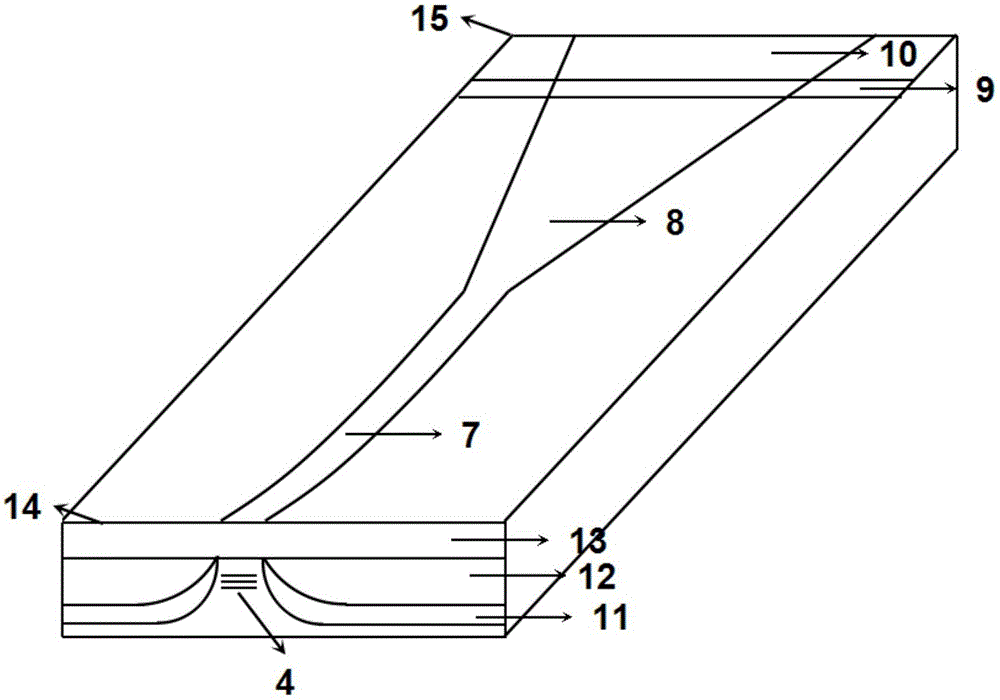

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

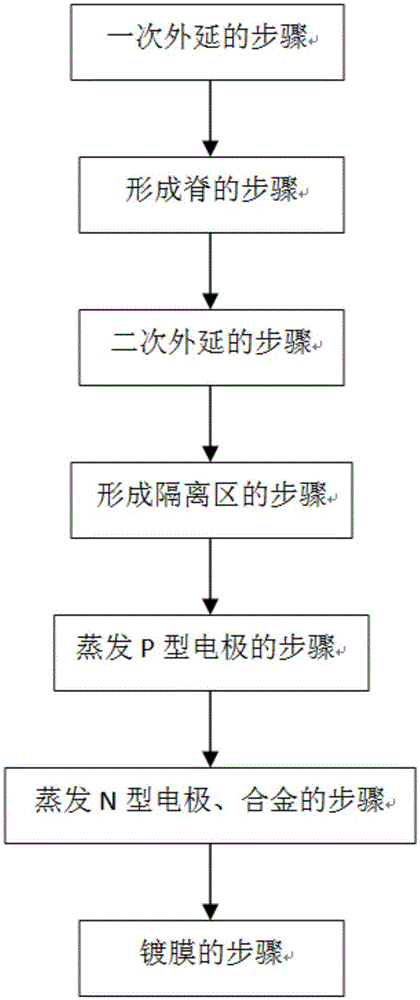

[0032] The invention relates to a method for preparing a superluminescent light-emitting diode chip, such as figure 1 Shown, this preparation method comprises the steps:

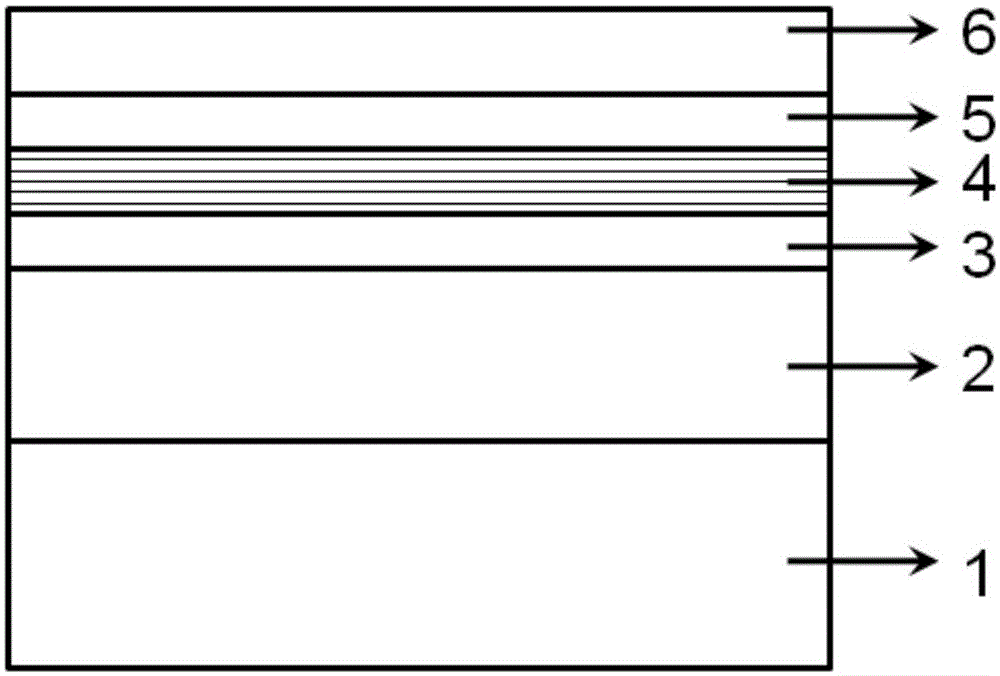

[0033]1. One-time epitaxy step: grow 1 μm N-InP buffer layer 2 on N-InP substrate 1 by MOCVD method, then grow 80nm InGaAsP lower confinement layer 3 respectively, and then alternately grow 3 tensile strains of 1.1% and two InGaAsP quantum wells with a compressive strain of 1.2%, the thicknesses of the tensile strain well and the compressive strain well are respectively 10nm and 5nm, the PL peak wavelengths are both 1300nm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com