Vertical distribution feedback surface emitting laser and preparation method thereof

A technology of surface-emitting lasers and vertical distribution, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of difficult to achieve mass production of narrow line width application requirements, poor wavelength stability, low power density, etc., and achieve easy mass production , stable wavelength, and reduced spectral linewidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

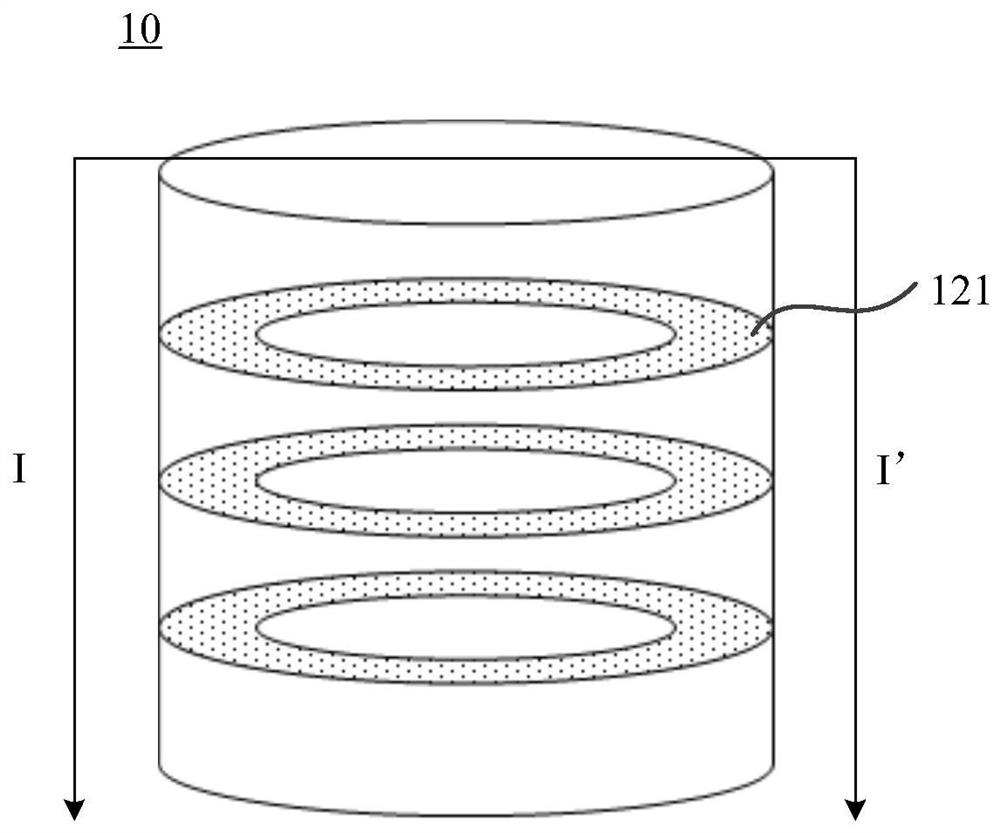

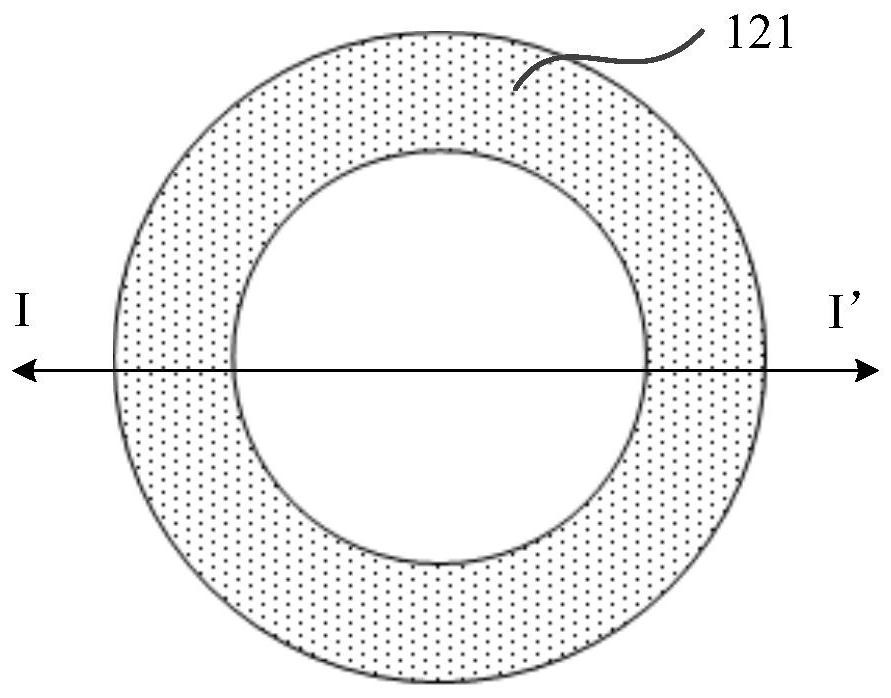

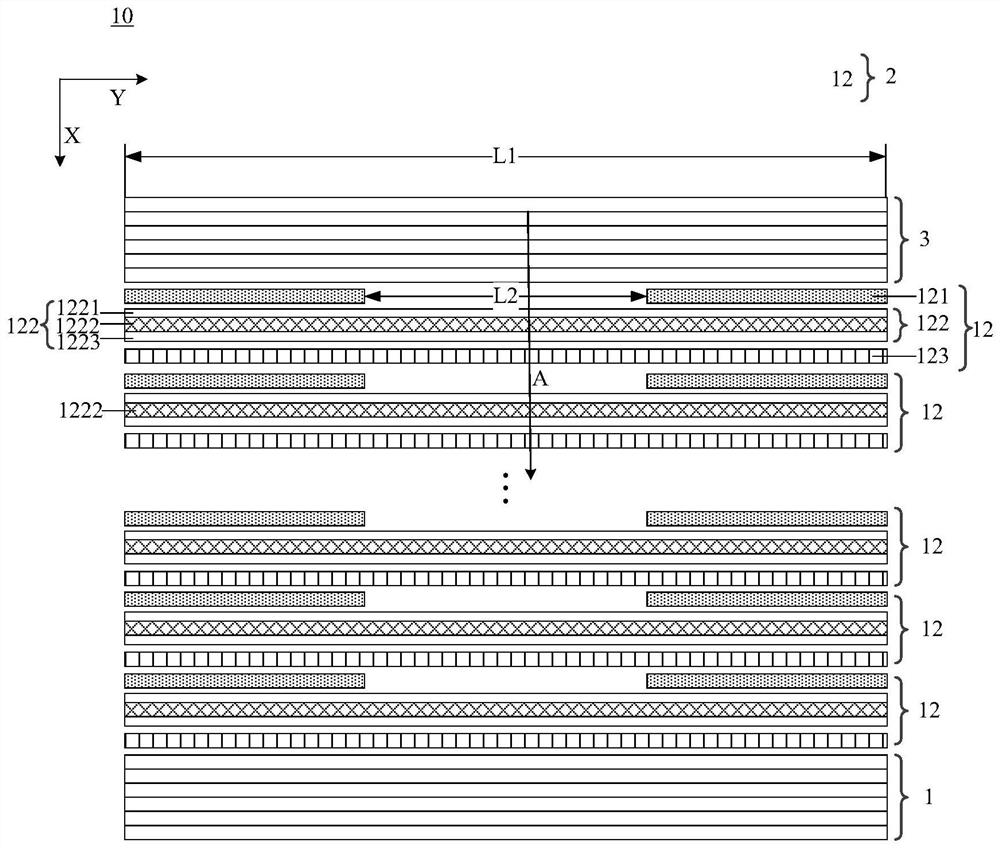

[0036] An embodiment of the present invention provides a vertical distribution feedback surface emitting laser. figure 1 It is a schematic structural diagram of a vertical distribution feedback surface emitting laser provided by an embodiment of the present invention; figure 2 yes figure 1 A schematic diagram of the top view structure of an oxide layer provided in ; image 3 yes figure 1 Schematic cross-section of a vertically distributed feedback surface emitting laser along the I-I' direction in . Such as Figure 1-Figure 3 As shown, the vertical distributed feedback surface emitting laser 10 includes a first cavity surface 1, a periodic distributed feedback structure 2 and a second cavity surface 3; along the first direction (as shown in the X direction in the figure), the periodic distributed feedback structure 2 It includes a plurality of distributed feedback structures 12, and the distributed feedback structure 12 includes an oxide layer 121, an active region 122 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com