External resonator-type light emitting device

一种外部谐振器、发光装置的技术,应用在光学谐振腔的结构、仪器、光学等方向,能够解决光强度变化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

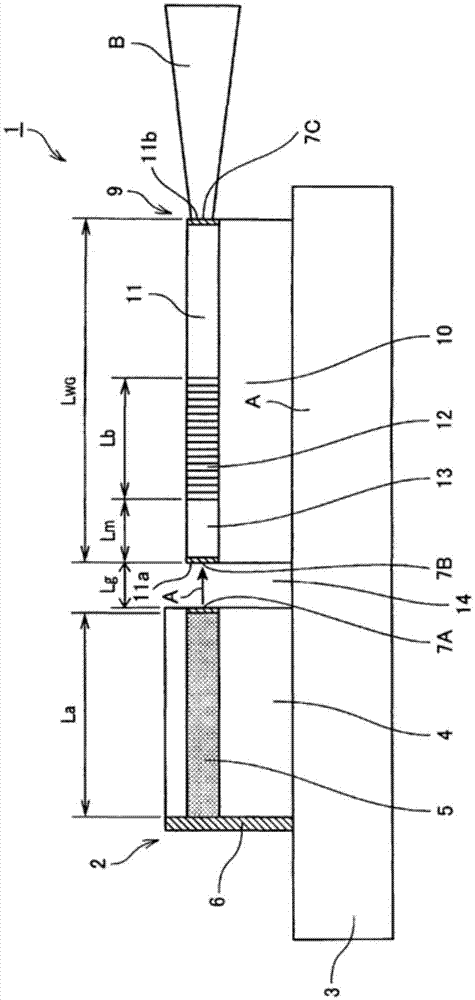

[0157] made as Figure 1-Figure 3 device shown.

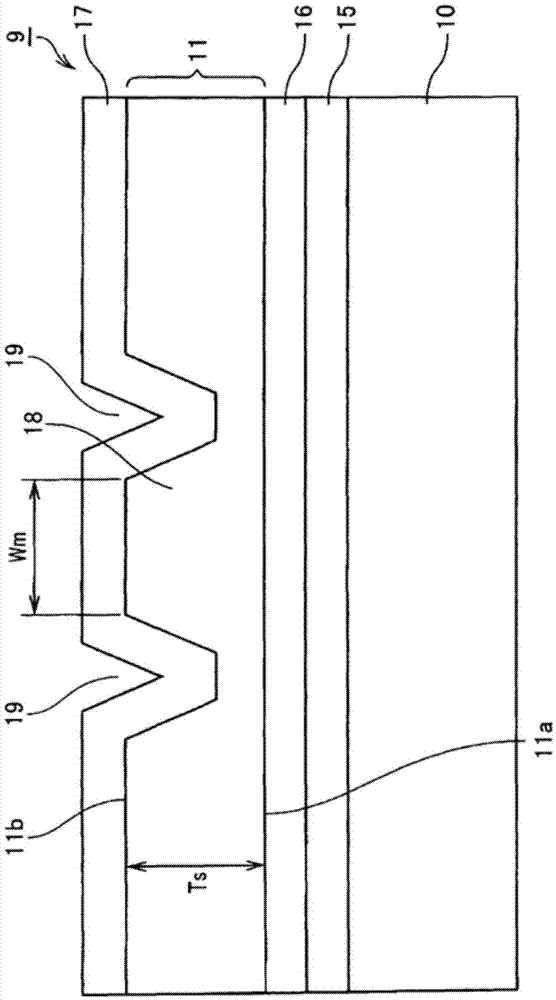

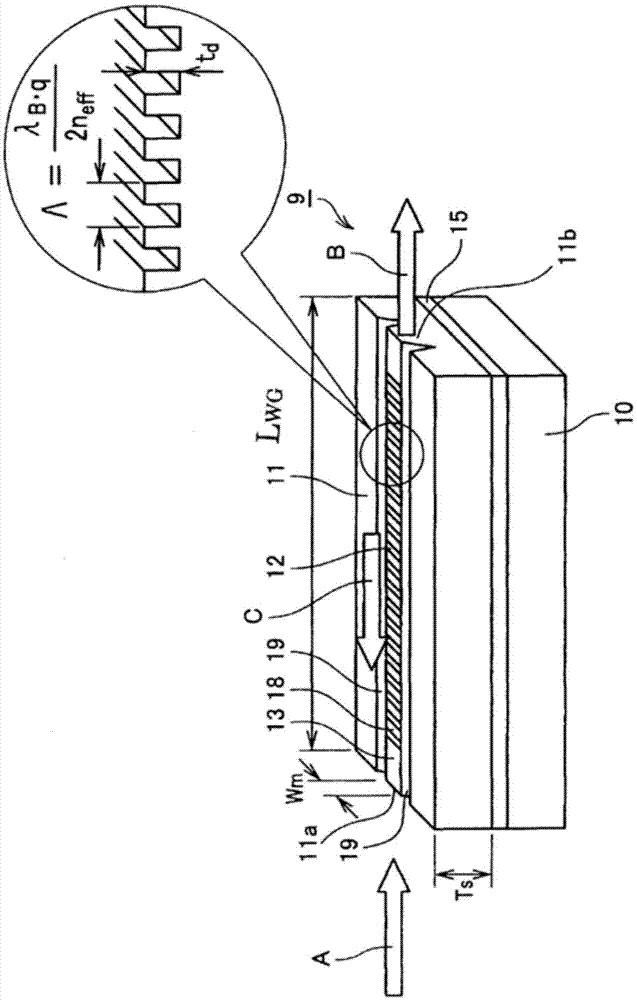

[0158] Specifically, a Ni film is formed on a substrate obtained by z-cutting MgO-doped lithium niobate crystals, and a grating pattern is fabricated in the y-axis direction by photolithography. Afterwards, reactive ion etching was performed using the Ni pattern as a mask to form grating grooves with a pitch interval Λ of 180 nm and a length Lb of 100 μm. The groove depth of the grating is 300nm. In addition, in order to form an optical waveguide propagating in the y-axis, the grating portion was subjected to groove processing with a width Wm of 3 μm and a Tr of 0.5 μm using an excimer laser. Further, on the trench formation surface, a 0.5 μm SiO 2 For the formed buffer layer 17, a black LN substrate was used as a support substrate, and the grating formation surface was bonded.

[0159] Next, the black LN substrate side was attached to a polishing table, and the rear surface of the LN substrate on which the grating was form...

Embodiment 2

[0184] Produced in the same manner as in Example 1 figure 1 , image 3 device shown. However, the cross-sectional shape of the grating element 21D is Figure 11 (a) The shape shown.

[0185] Specifically, a 0.5 μm lower clad layer of SiO was formed on a support substrate 10 made of quartz by a sputtering device. 2 layer 16, on which 1.2μm Ta 2 o 5 film, forming a high refractive index layer. Next, in Ta 2 o 5 On top, Ti is formed into a film, and a grating pattern is produced by an EB drawing device. Thereafter, fluorine-based reactive ion etching was performed using the Ti pattern as a mask to form a Bragg grating with a pitch interval Λ of 238.5 nm and a length Lb of 100 μm. The groove depth td of the grating is 40 nm.

[0186] Furthermore, in order to form the optical waveguide 20, reactive ion etching was carried out by the same method as above to etch such that the width was Wm3 μm, the optical waveguide 20 remained on both sides, and the high refractive index l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com