External resonator type light emitting device

A technology of external resonators and light-emitting devices, applied in the structure of optical resonant cavities, instruments, optics, etc., can solve problems such as light intensity changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0137] (Example)

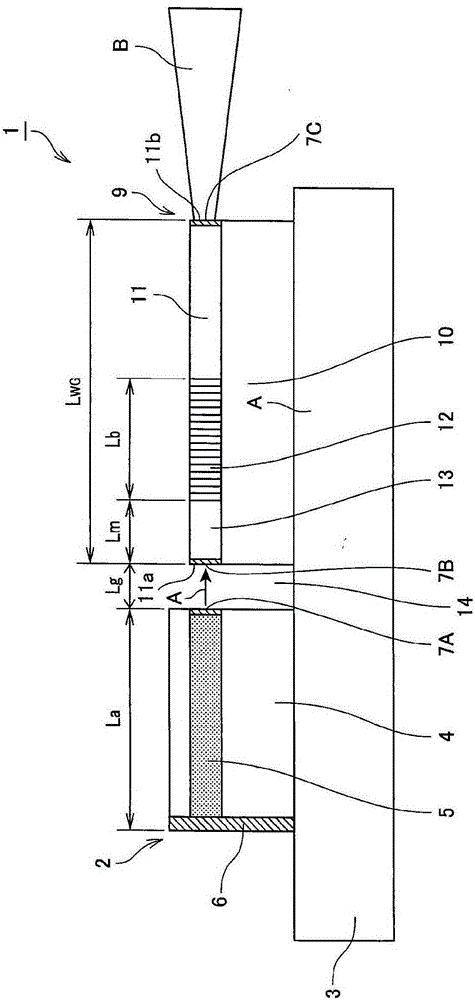

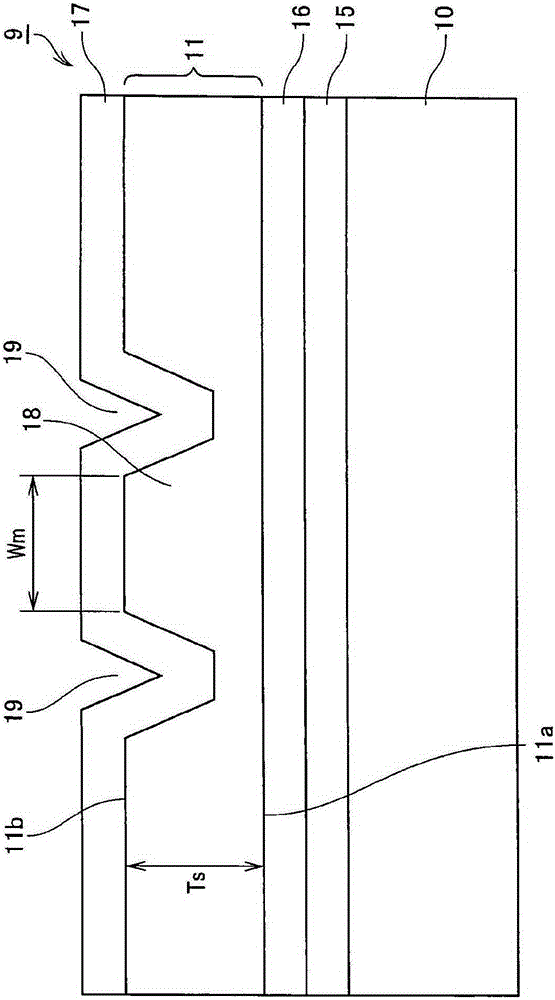

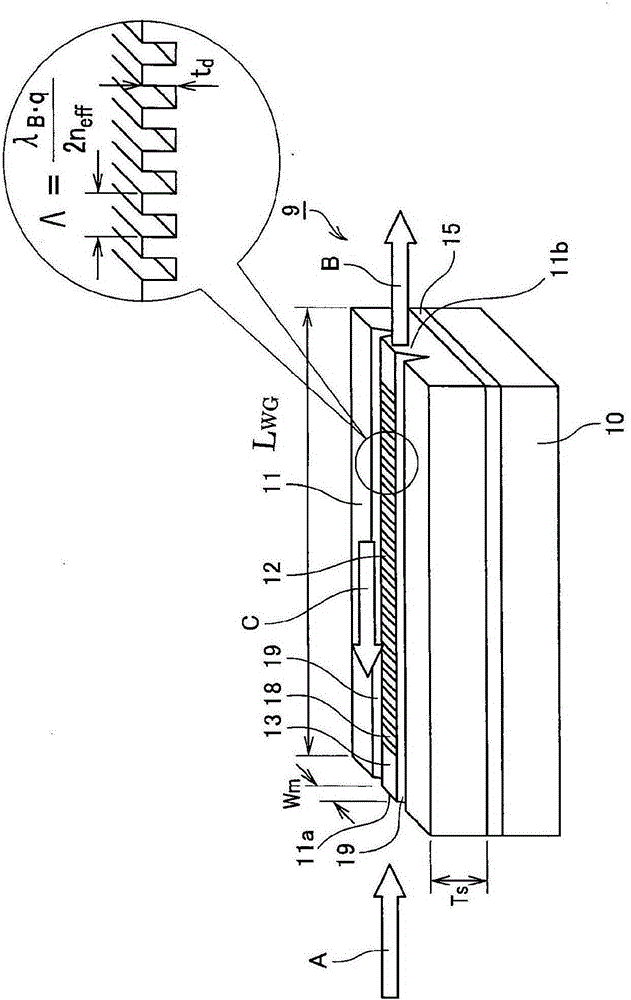

[0138] made as Figure 1-Figure 3 device shown.

[0139] Specifically, a film of Ni is formed on a substrate in which MgO-doped lithium niobate crystals are cut into z-plates, and a grating pattern is fabricated in the y-axis direction by photolithography. Thereafter, reactive ion etching is performed through the mask Ni pattern, thereby forming a pitch (pitch) interval Λ of 180 nm and a length L b 100μm grating groove. The groove depth of the grating is 300nm. In addition, in order to form an optical waveguide propagating in the y-axis, the grating portion was subjected to groove processing with a width Wm of 3 μm and a Tr of 0.5 μm using an excimer laser. Further, on the trench formation surface, the SiO 2 The buffer layer 17 formed was formed at a thickness of 0.5 μm, and a black LN substrate was used as a support substrate, and the grating formation surface was bonded. Here, the black LN substrate refers to, from LN (LiNbO 3 ) crystallization remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com