Laser-based frequency tripling device and laser system

A frequency doubling and frequency doubling technology, applied in the field of lasers, can solve the problems of complex optical path structure and locking loop, decrease in output power, limited damage threshold, etc., achieve simple and compact optical path structure, reduce the possibility of loss of lock, The effect of simplifying the locking circuit section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

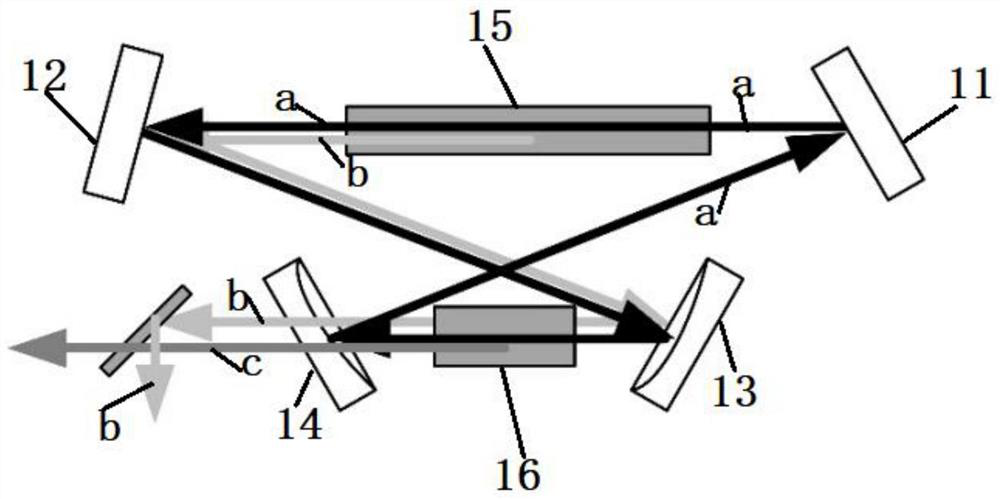

[0032] Such as figure 1 As shown, a laser-based triple frequency device, including,

[0033] The first frequency doubling unit 11 is arranged at a first predetermined position; the first predetermined position is that the first included angle between the first frequency doubling unit 11 and the optical path trajectory line is 0°-33°, wherein the first included angle It is an acute angle, and the acute angle range is preferably 5°-33°.

[0034] The second frequency doubling unit 12 is arranged at a second predetermined position; the second predetermined position is that the second included angle between the second frequency doubling unit 12 and the optical path trajectory line is 0° to 33°, wherein the second included angle is an acute angle. The first frequency multiplication unit 11 and the second frequency multiplication unit 12 are arranged symmetrically.

[0035] The nonlinear crystal 15 is arranged between the first frequency doubling unit 11 and the second frequency d...

Embodiment 2

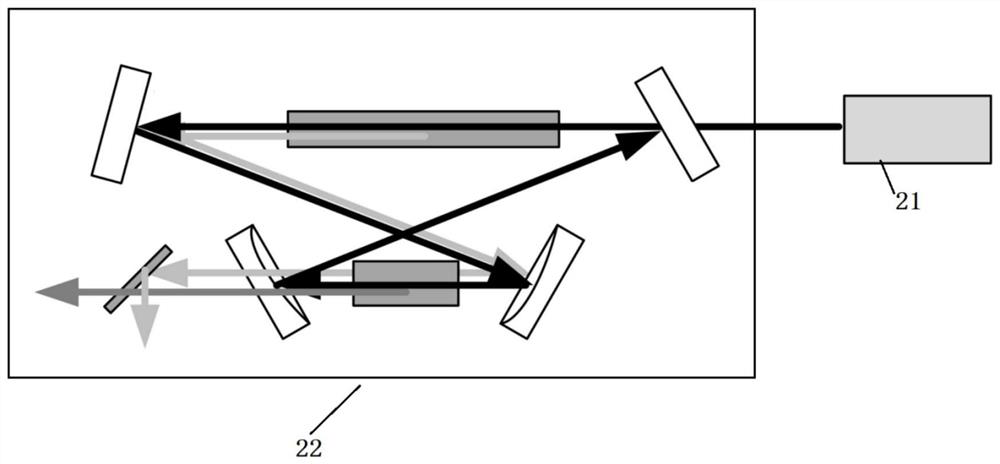

[0045] Such as figure 2 Shown, on the other hand, the present application provides a kind of laser system again, wherein: comprise the triple frequency device described in any item above,

[0046] The light source 21 is used to output an optical signal with a predetermined wavelength; the predetermined wavelength of the optical signal is 1050nm to 1200nm.

[0047] The frequency tripler 22 is used to receive the optical signal of the predetermined wavelength; perform frequency triple processing on the optical signal of the predetermined wavelength to form a 355nm laser signal.

[0048] The specific working principle is:

[0049] Using high-power continuous single-frequency 1064nm fundamental frequency laser a signal, the fundamental frequency laser a is coupled into the triple frequency device, and the 1064nm fundamental frequency laser a is input to the first frequency doubling unit, the nonlinear crystal, the second frequency doubling unit, and the second frequency doubling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com