Three-dimensional light distribution detection apparatus for optical focus area

A focus area and light intensity distribution technology, applied in the optical field, can solve the problems of high positioning requirements for machining, inconvenient adjustment and use, and high requirements for devices, and achieve the effect of low positioning requirements for machining, convenient adjustment and use, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

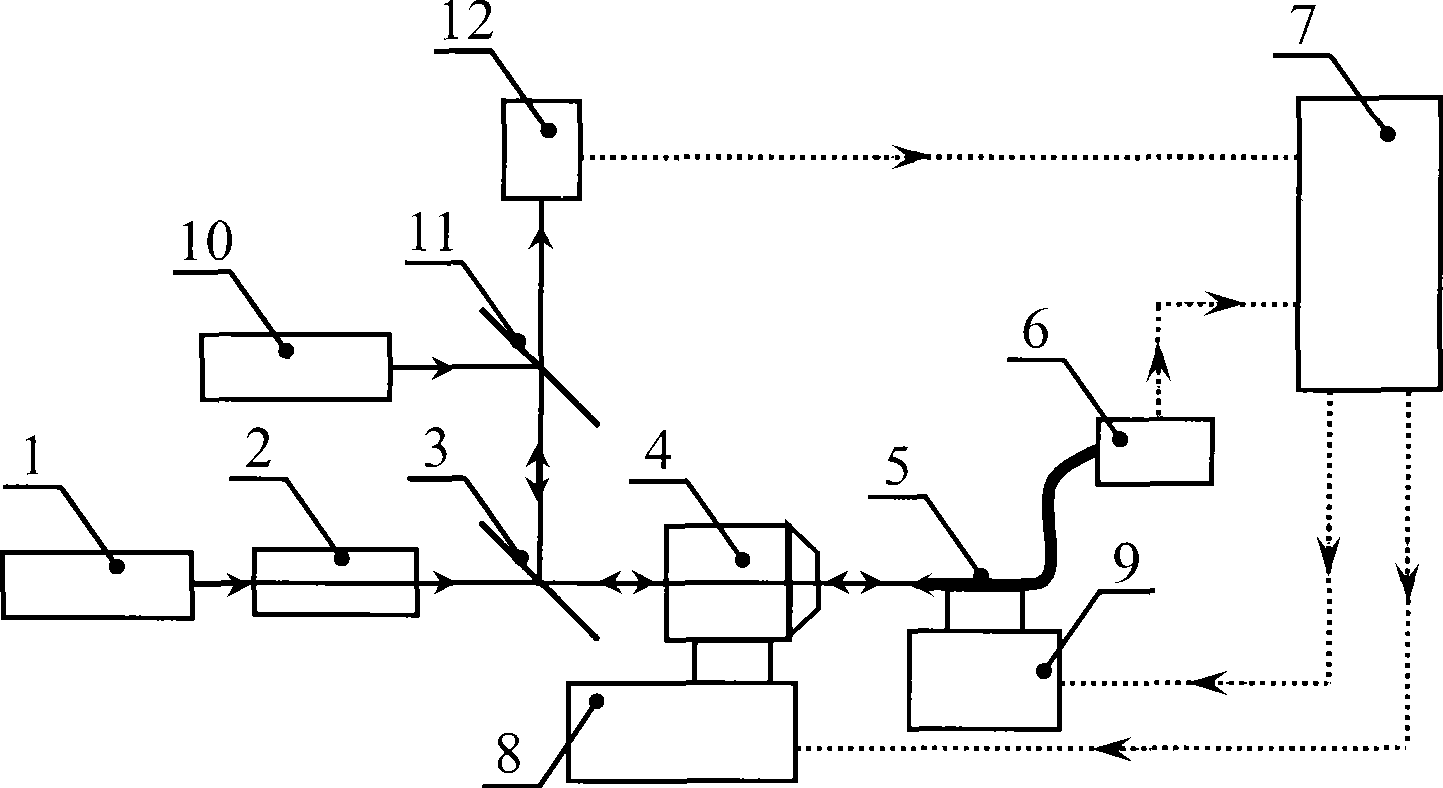

[0022] Such as figure 1 The three-dimensional light intensity distribution detection device in the optical focus area includes a system light source 1, a beam shaper 2, a spectral beam splitter 3, an objective lens 4, an optical fiber probe 5, a photoelectric sensor 6, an analysis control unit 7, a one-dimensional mobile platform 8, and a three-dimensional mobile platform. Platform 9 , monitoring light source 10 , beam splitter 11 and image collector 12 . The beam shaper 2, the spectral beam splitter 3, and the objective lens 4 are successively arranged on the optical path of the output beam of the system light source 1, the needle tip of the fiber probe 5 is set corresponding to the beam output direction of the objective lens 4, and the light energy output end of the fiber probe 5 is connected to the photoelectric Sensor 6 is connected. The one-dimensional mobile pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com