Method for optimizing photonic crystal surface emitting laser

A technology for emitting lasers and photonic crystals, applied in the legal field, can solve problems such as low luminous efficiency, large threshold current, and mode leakage, and achieve the effects of simple preparation process, strong modulation characteristics, and high transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

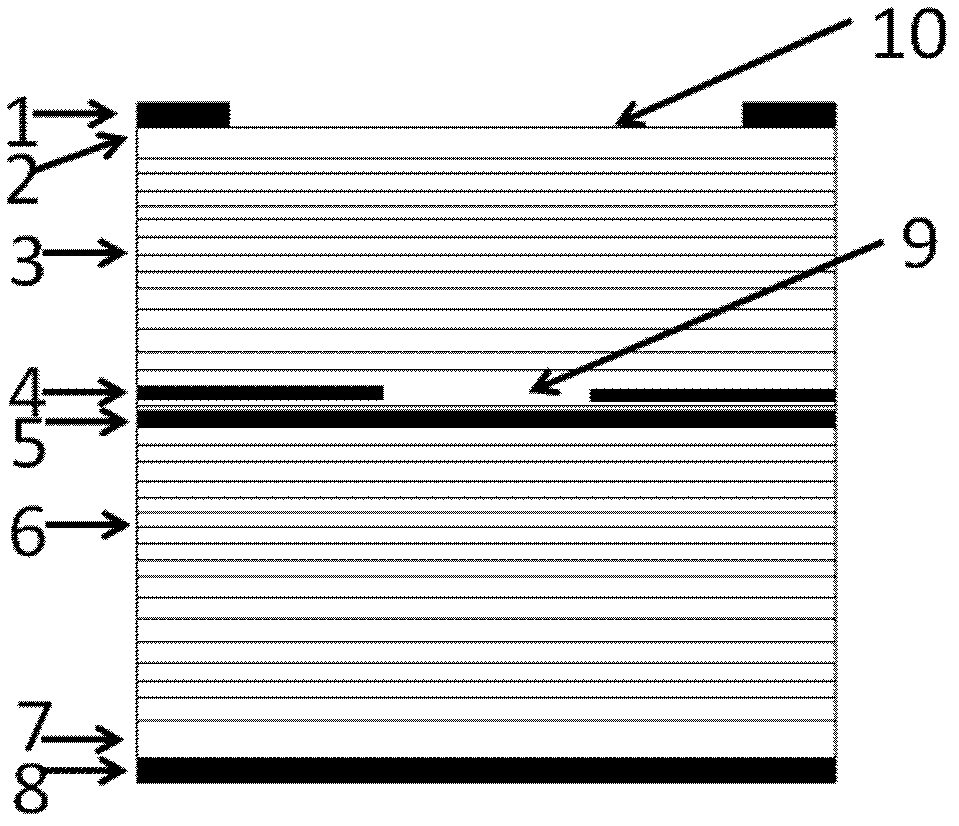

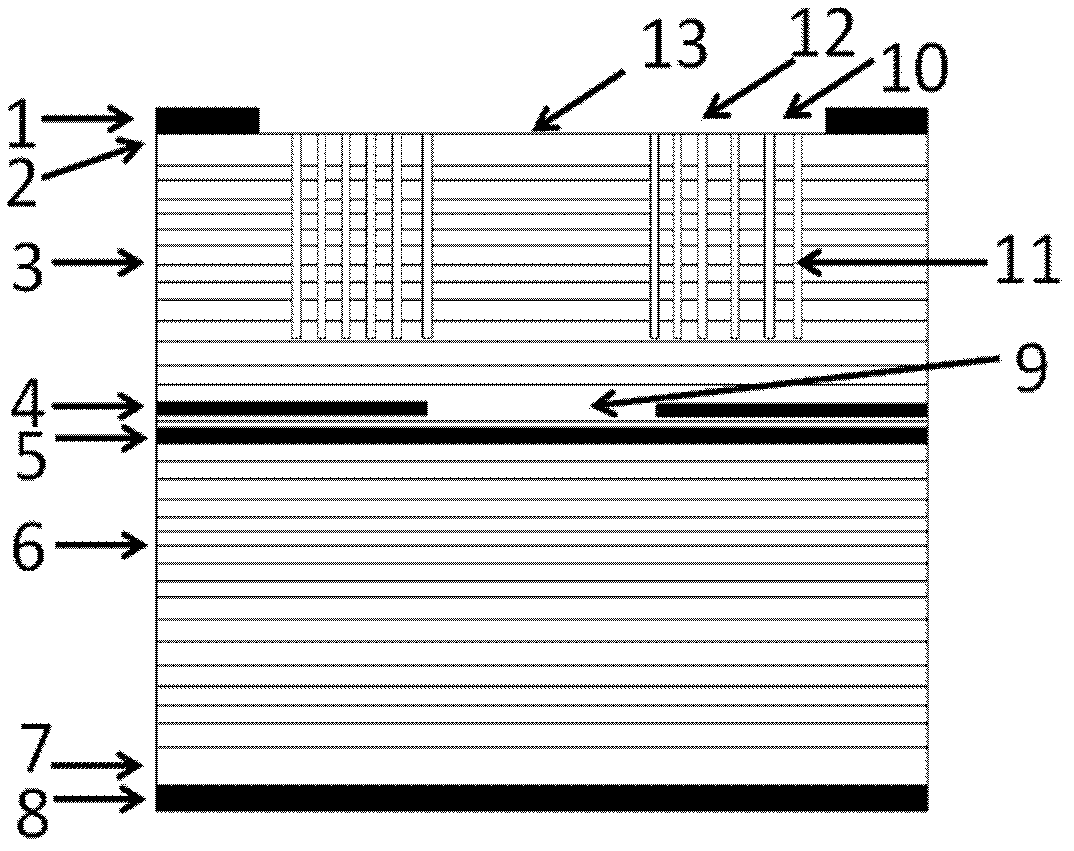

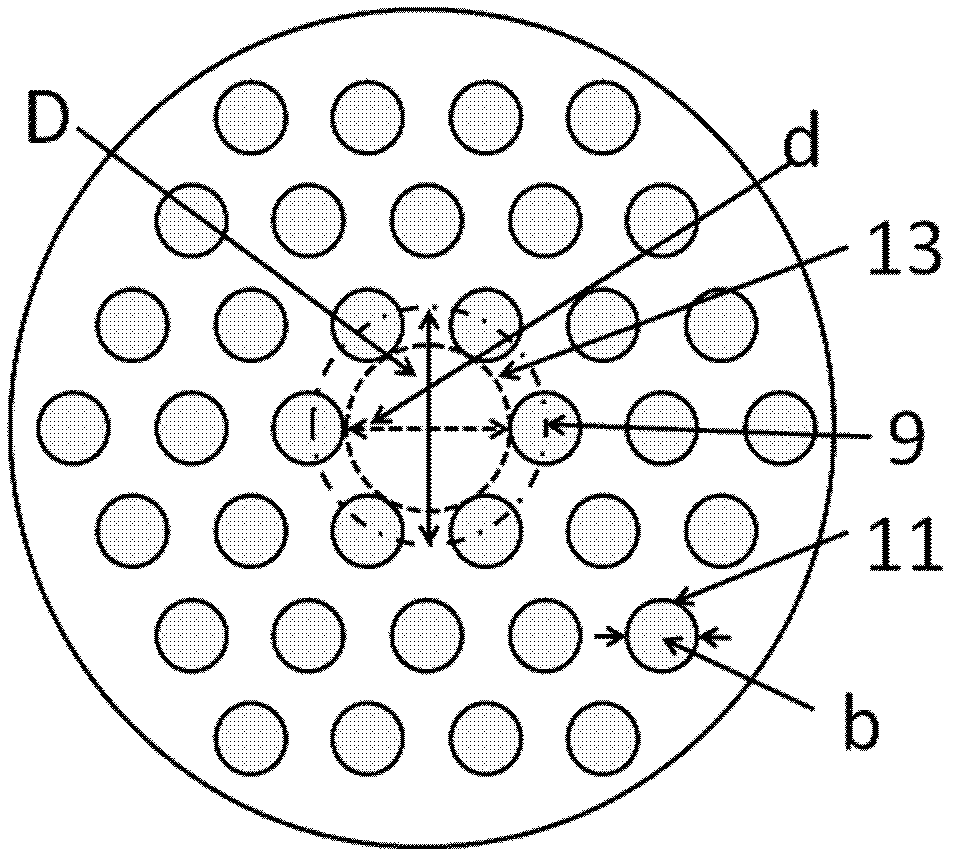

[0020] In order to verify the design scheme, we used the following method to prepare the device. A structured epitaxial wafer is selected, and an oxidation-confined surface-emitting laser in which the oxidation hole 9 and the photonic crystal defect hole 13 meet the matching coupling conditions is prepared through a conventional semiconductor process. Cleavage, bonding, testing. It is found that the threshold current of the device is an order of magnitude lower than that of the device without matching coupling, and the single fundamental mode power is increased by 30% compared with the device without matching coupling. The feasibility of our scheme is verified.

[0021] (Take a single-hole defect with a wavelength of 850nm, a photonic crystal lattice period of 5 microns, a photonic crystal air hole diameter of 2.5 microns, and a seven-hole defect structure with a photonic crystal period of 2 microns and a photonic crystal air hole diameter of 1 micron as an example)

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com