Single-laser vertical cavity surface emitting laser (VCSEL) chip and fabrication method thereof

A laser and chip technology, applied in the direction of lasers, laser parts, semiconductor lasers, etc., can solve the problems of multiple beams, troublesome fitting, low power, etc., and achieve high output power, high cost of improved fitting, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

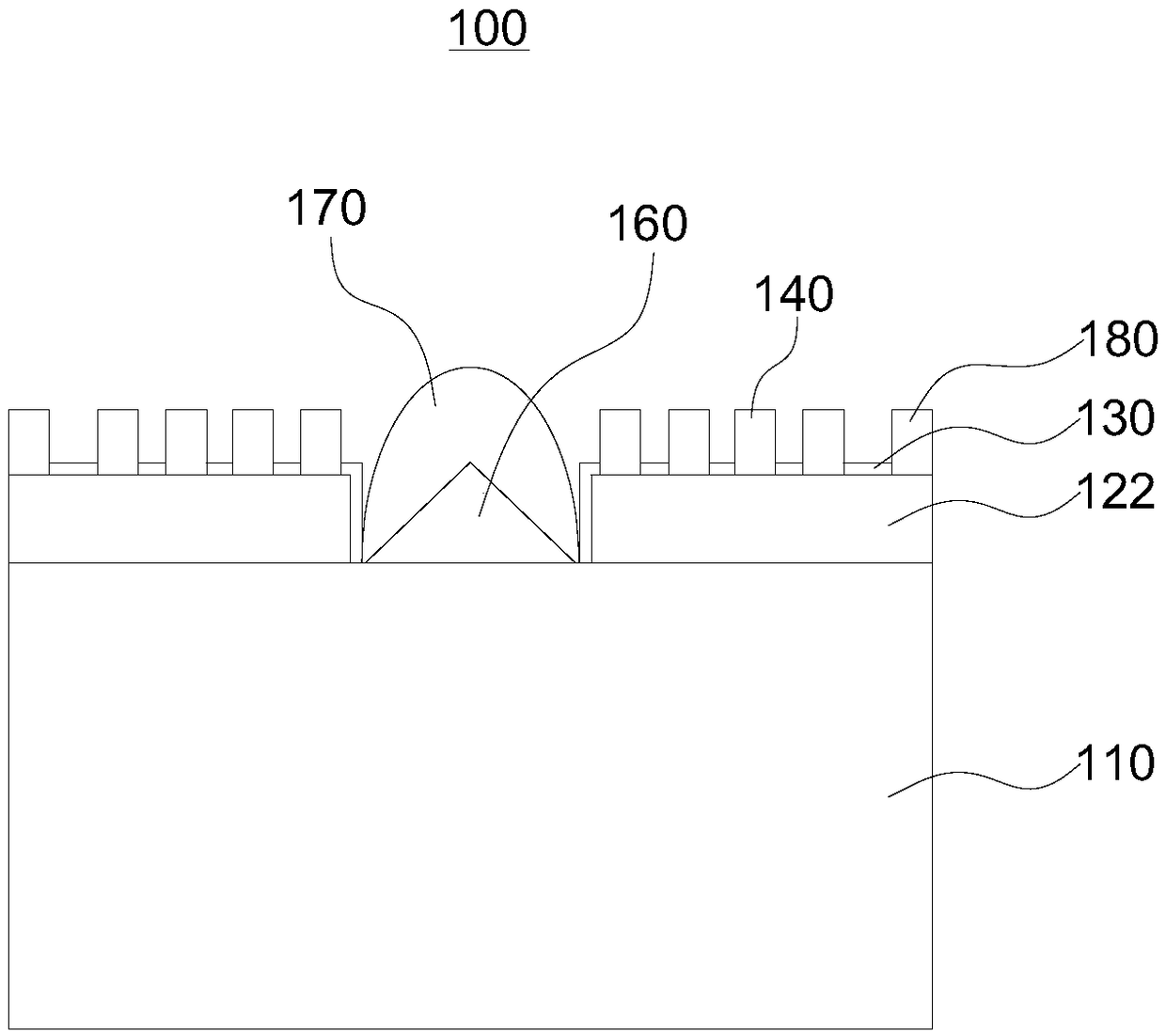

[0037] Please refer to figure 1 This embodiment provides a VCSEL chip 100 with a single laser beam, which includes a GaAs substrate 110 , an epitaxial layer 120 , a SiNx layer 130 , a grating layer 140 , a triangular mirror 160 , an epoxy resin layer 170 and an electrode 180 .

[0038] Wherein, the GaAs substrate 110 is used as the bottom layer to support the above-mentioned epitaxial layer 120 , SiNx layer 130 , grating layer 140 , triangular mirror surface 160 , epoxy resin layer 170 and electrode 180 .

[0039] The epitaxial layer 120 is grown on the surface of the GaAs substrate 110 . The epitaxial layer 120 is etched with a groove 121 and a plurality of independent epitaxial units 122 . The plurality of epitaxial units 122 are evenly distributed along the centerline of the groove 121 . In this embodiment, the epitaxial layer 120 may be a conventional epitaxial layer 120 or a specially grown epitaxial layer 120 .

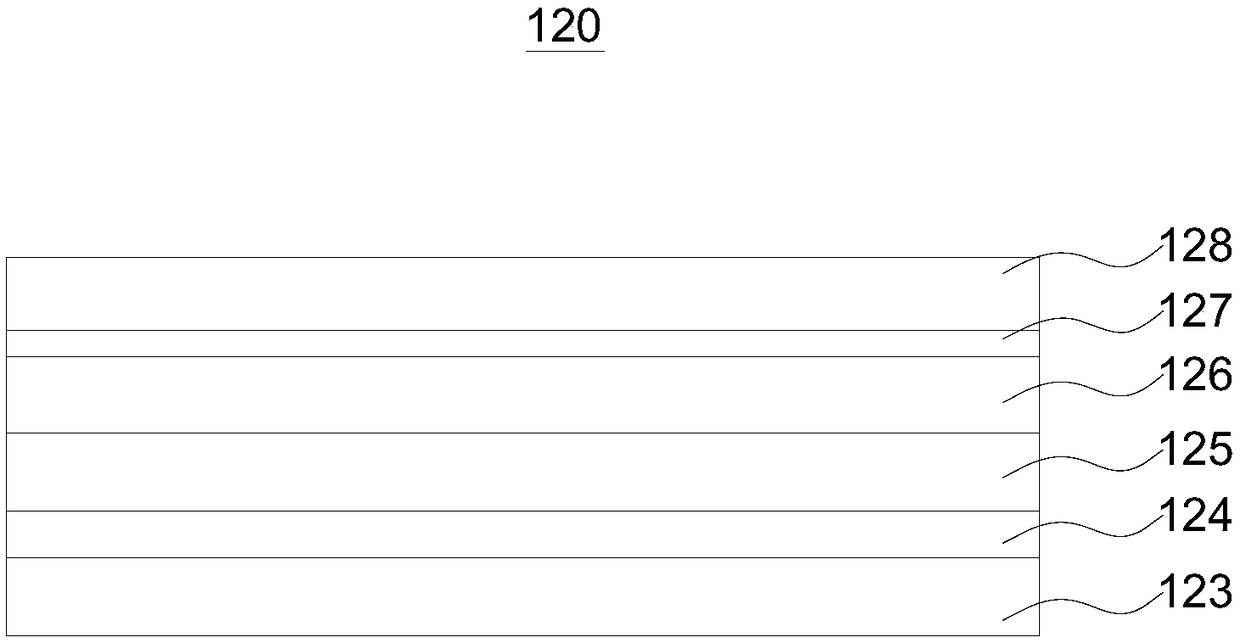

[0040] Preferably, in this embodiment, the epitaxial laye...

no. 2 example

[0056] The present embodiment provides a method for preparing a single-beam laser VCSEL chip 100, which includes the following steps:

[0057] S1. In a reaction chamber with a temperature of 650-750° C. and a pressure of 40-60 mbar, the surface of the GaAs substrate 110 is first cleaned with concentrated sulfuric acid, and then the surface of the GaAs substrate 110 is cleaned with ammonia water. The surface of bottom 110 grows N-DBR layer 123, GaAs buffer layer 124, MQW layer 125 successively from bottom to top (growing MQW layer 125 is to grow a layer of AlGaAs layer on the surface of GaAs buffer layer 124 earlier, then on the surface of AlGaAs layer A layer of AlAs layer is grown, the overlapping AlGaAs layer and AlAs layer form a pair of composite layers, and then AlGaAs layer and AlAs layer are alternately grown on the surface of the AlAs layer to form 35-40 pairs of composite layers, and 35-40 pairs of composite layers are used as MQW layer 125), Al0.98Ga0.02As layer 126,...

no. 3 example

[0066] The present embodiment provides a method for preparing a single-beam laser VCSEL chip 100, which includes the following steps:

[0067] S1. Growing an epitaxial layer 120 on the surface of the GaAs substrate 110 in a reaction chamber with a temperature of 650-750° C. and a pressure of 40-60 mbar;

[0068] S2. Perform patterned photolithography on the epitaxial layer 120, etch to form a groove 121 and a plurality of mutually independent epitaxial units 122, and the plurality of epitaxial units 122 are evenly distributed along the centerline of the groove 121;

[0069] S3, depositing a SiNx layer 130 on the surface of the epitaxial unit 122;

[0070] S4. Fabricate a grating layer 140 on the surface of the SiNx layer 130 and make the diffraction direction of the grating proceed along the horizontal direction of the GaAs substrate 110;

[0071] S5. Perform patterned photolithography in the groove 121, deposit Ag and then peel off, and then repeat the deposition on the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com