Heat conducting nylon composite material and preparation method thereof

A technology of nylon composite materials and thermally conductive fillers, which is applied in the field of preparation of composite materials, thermally conductive nylon composite materials, and thermally conductive nylon composite materials. It can solve the problems of increasing production costs, achieve improved thermal conductivity, good comprehensive performance, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

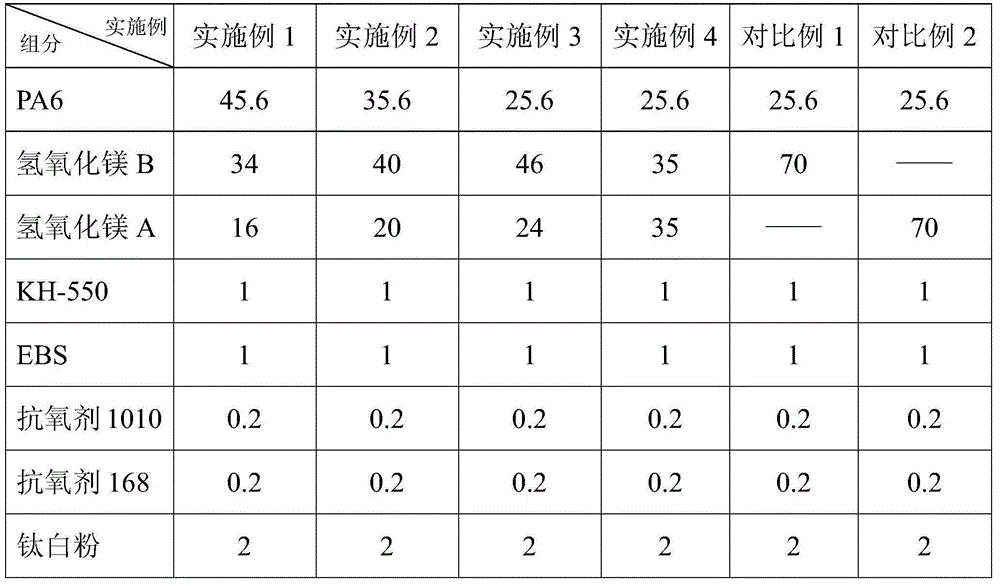

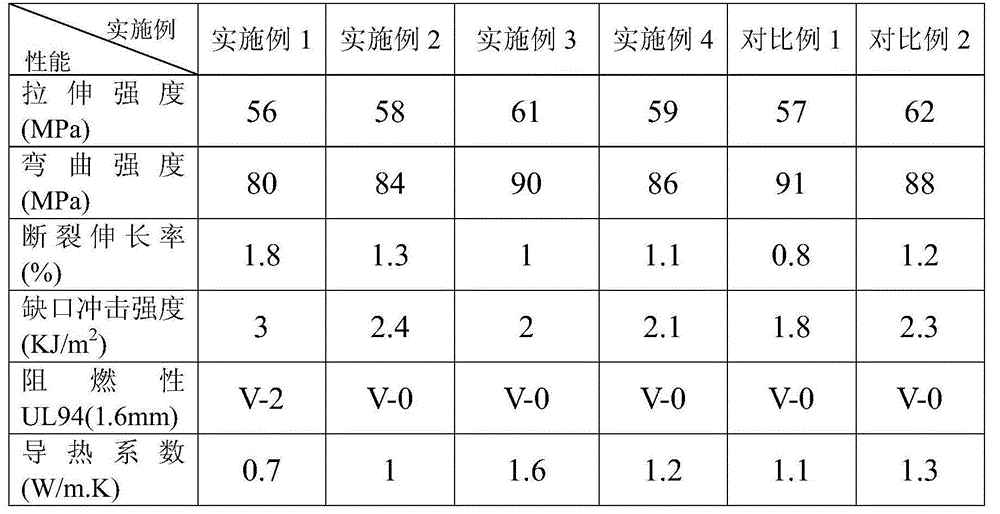

[0052] Below in conjunction with embodiment the present invention is described in further detail.

[0053] The components and contents of the thermally conductive nylon composite materials of Examples 1-4 and Comparative Examples 1 and 2 are shown in Table 1. Among them, nylon 6 (PA6) is the base resin, the coupling agent is KH-550, the antioxidant is a mixture of 1010 and 168; the lubricant is EBS (N,N'-ethylene bisstearamide), the whitening agent For titanium dioxide.

[0054] Thermally conductive fillers include magnesium hydroxide A and magnesium hydroxide B, the particle size of magnesium hydroxide A is 200-1500 mesh, the particle size of magnesium hydroxide B is 5000-12000 mesh; the particle size of magnesium hydroxide A and magnesium hydroxide B is The particle size is arbitrarily selected within the above range, specifically, the particle size of magnesium hydroxide A is 800 mesh, and the particle size of magnesium hydroxide B is 10000 mesh.

[0055] Table 1. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com