Thermal expansion fluid composite spherically-shaped cavity drive type robot soft hand

A thermal expansion, robotic technology, applied in the directions of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of limited degrees of freedom, poor operational safety, and insufficient ability to stably and reliably grasp complex-shaped objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

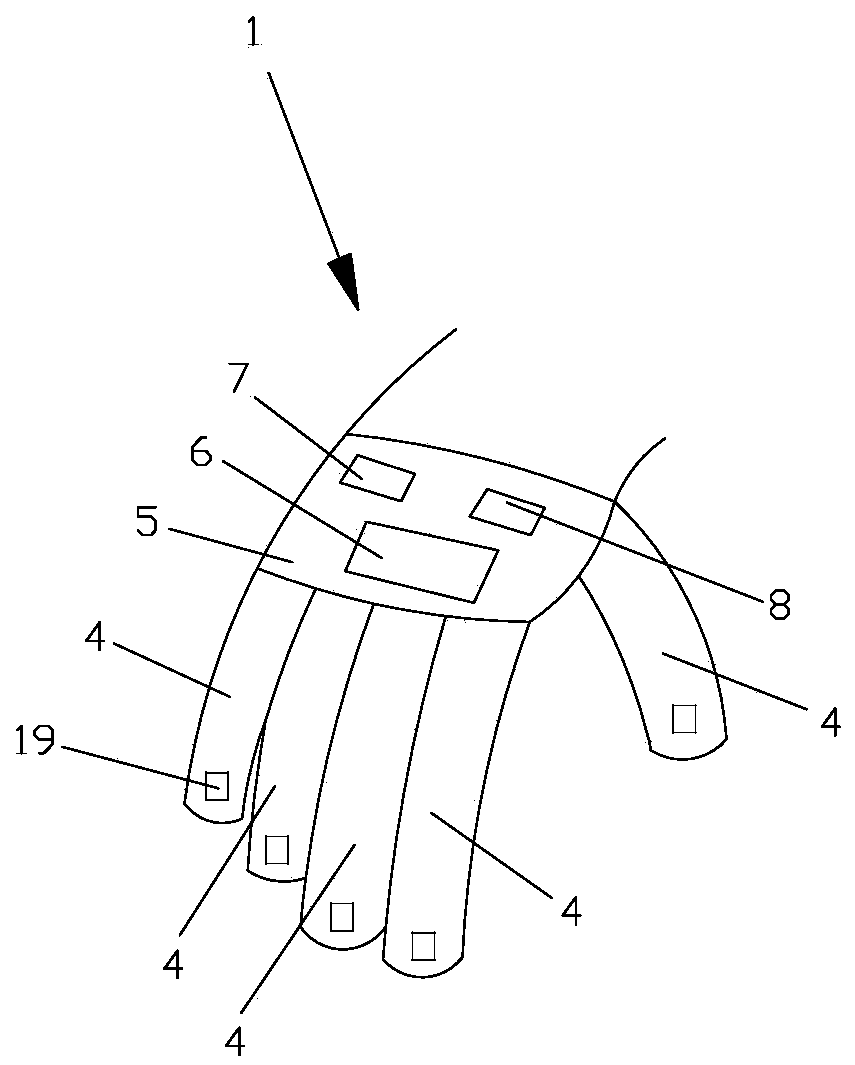

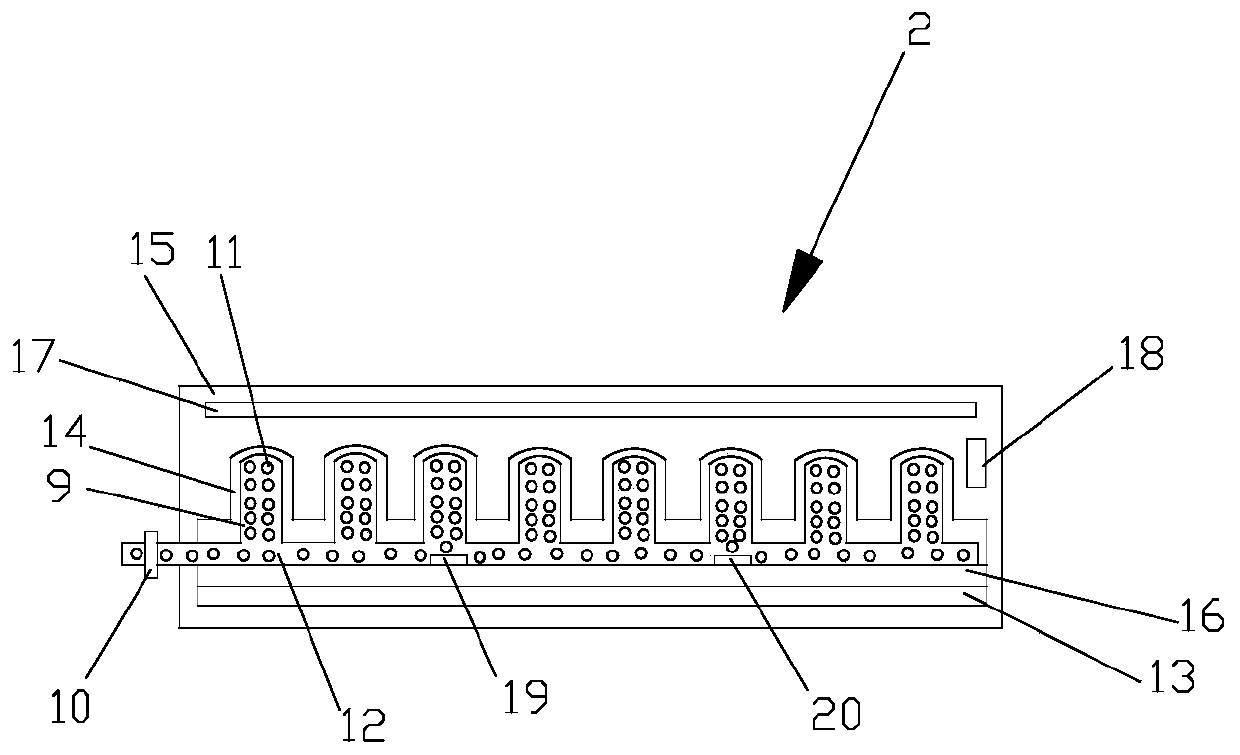

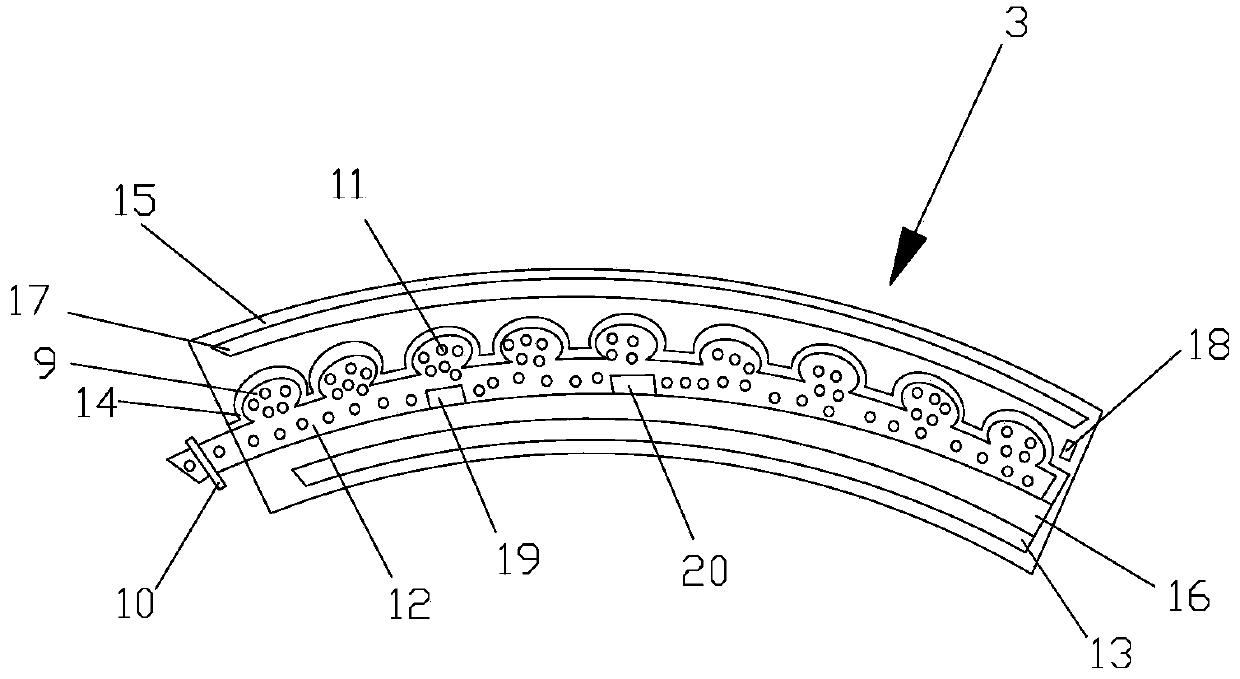

[0044] Embodiment 1: A thermal expansion fluid composite special-shaped cavity driven robot soft hand 1 using a thermal expansion fluid and a shape memory alloy composite special-shaped cavity unilateral driver 2.

[0045] Example 1 of the present invention adopts a thermal expansion fluid and a shape memory alloy composite special-shaped cavity unilateral driver 2 for the structure diagram of the thermal expansion fluid composite special-shaped cavity-driven robotic soft hand 1 figure 1 ;The structure diagram of the undriven state of the unilateral actuator of the thermal expansion fluid and shape memory alloy composite special-shaped cavity is shown in figure 2 ; The structure diagram of the single-side driver driving state 3 of the thermal expansion fluid and shape memory alloy composite special-shaped cavity is shown in image 3 .

[0046] The thermal expansion fluid composite special-shaped cavity-driven robotic soft hand 1 of embodiment 1 of the present invention includes: fiv...

Embodiment 2

[0053] Embodiment 2: The thermal expansion fluid composite special-shaped cavity driven robot soft hand 1 using the double-sided driver 21 of the composite special-shaped cavity with thermal expansion fluid and electric heating material.

[0054] Embodiment 2 of the present invention adopts a thermal expansion fluid and an electrically controlled heating material to composite a special-shaped cavity double-side driver for a structural schematic diagram of a thermal expansion fluid composite special-shaped cavity driven robot soft hand 1 figure 1 ; The schematic diagram of the structure of the double-sided actuator 21 of the composite special-shaped cavity of the thermal expansion fluid and the electric control heating material is shown in Figure 4 .

[0055] The thermal expansion fluid composite special-shaped cavity-driven robot soft hand 1 of the second embodiment of the present invention includes: five thermal expansion fluid composite special-shaped cavity-driven robot soft fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com