Preparation method for Al-Ti-C system reaction cored wire

A powder core wire material, al-ti-c technology, applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of complicated process and equipment, restrictions on practical application, harsh preparation conditions, etc., and achieve The effect of uniform structure, good machining performance and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

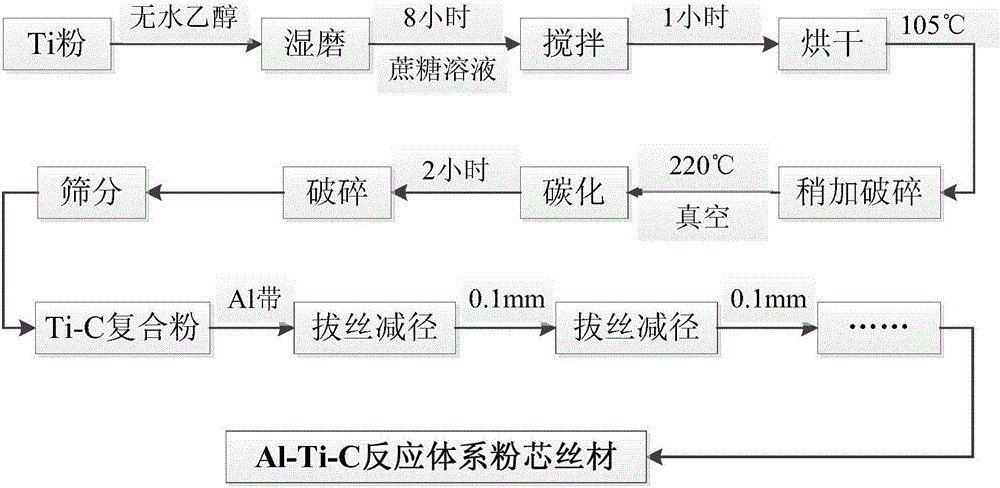

[0028] figure 1 It is a process flow chart of preparing Al-Ti-C system reaction powder core wire with -400 mesh titanium powder as raw material and absolute ethanol as organic solvent. Such as figure 1 Shown, the present invention prepares Al-Ti-C system reaction powder core wire material, implements according to the following steps:

[0029]Step 1: Weigh 1150g of Ti powder with a particle size of -400 mesh and a purity of 99.9%, put it in a sand mill, add 500ml of absolute ethanol, and wet mill for 8 hours. During the wet mill, add a small amount of ethanol according to the volatilization of ethanol to keep the sand The ethanol in the mill can infiltrate titanium powder. Weigh 342g of analytically pure sucrose (the molar ratio of titanium powder to sucrose is 24:1), dissolve it in 200ml of distilled water, pour the sucrose sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com