Novel anti-wrap guide plate device for pinch roller of steckel mill

A furnace coil rolling mill, anti-winding guide plate technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of no anti-winding device, easy strip rolls, unfavorable production of high-quality strip, etc. Avoid the effect of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

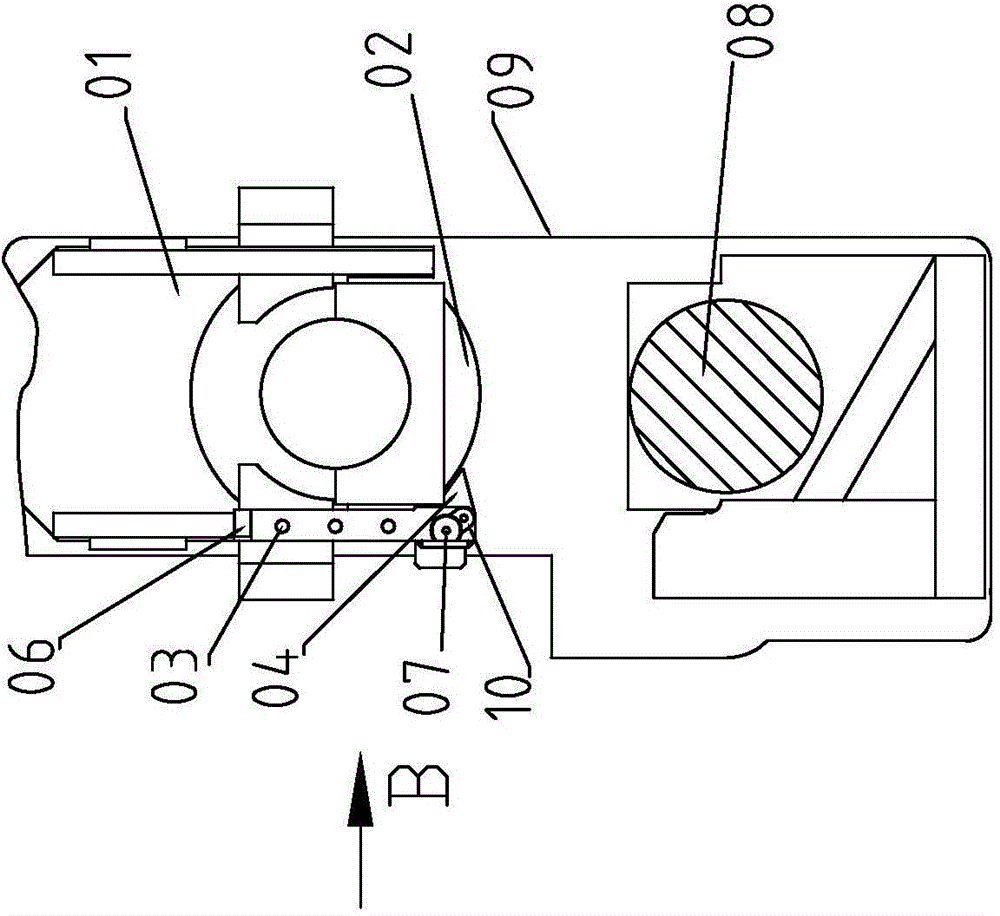

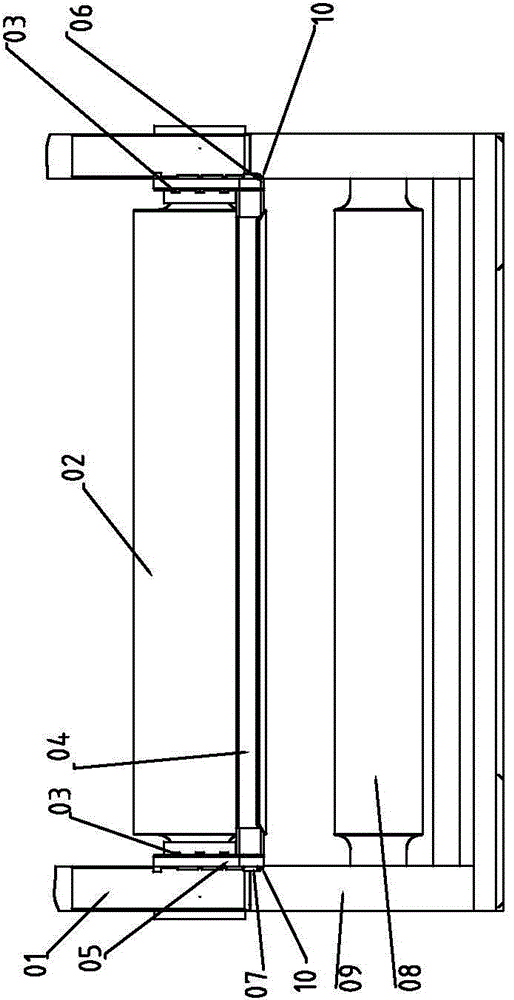

[0008] From attached figure 1 with attached figure 2 It can be seen from the figure that the scraper 04 is respectively connected with the left bracket 05 and the right bracket 06 through the pin shaft 07, and the pin shaft 07 is blocked by the baffle plate 10 to prevent the pin shaft 07 from moving. The left bracket 05 and the right bracket 06 are respectively fastened on the upper pinch roller bracket 01 by bolts 03, and the scraper 04 and the upper pinch roller 02 keep moving and move up and down in the pinch roller frame 09. The arc angle of the scraper 04 can be adjusted by the rotation of the pin shaft 07, the adjustment angle is consistent with the pinch roller, and it is close to the exit position of the upper pinch roller 02, and can move up and down with the upper pinch roller 02 And action. The tip of the scraper 04 is tangent to the outer circumference of the cross-section of the upper pinch roller 02 and keeps in close contact with the roller surface, and has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com