Magnesium/aluminum/titanium composite board cladding-rolling method

A technology of clad plate and magnesium alloy plate, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of unsatisfactory regional cladding effect, reducing the bonding strength of plates, unable to clad successfully, etc., to reduce impurities and harmful Gas, improved bonding strength, easy deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

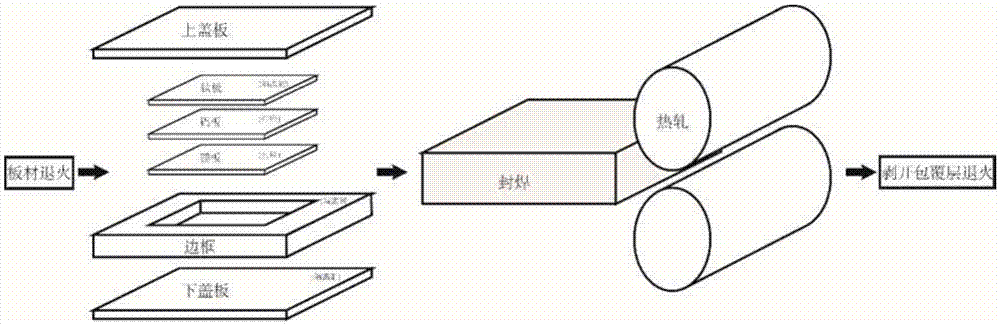

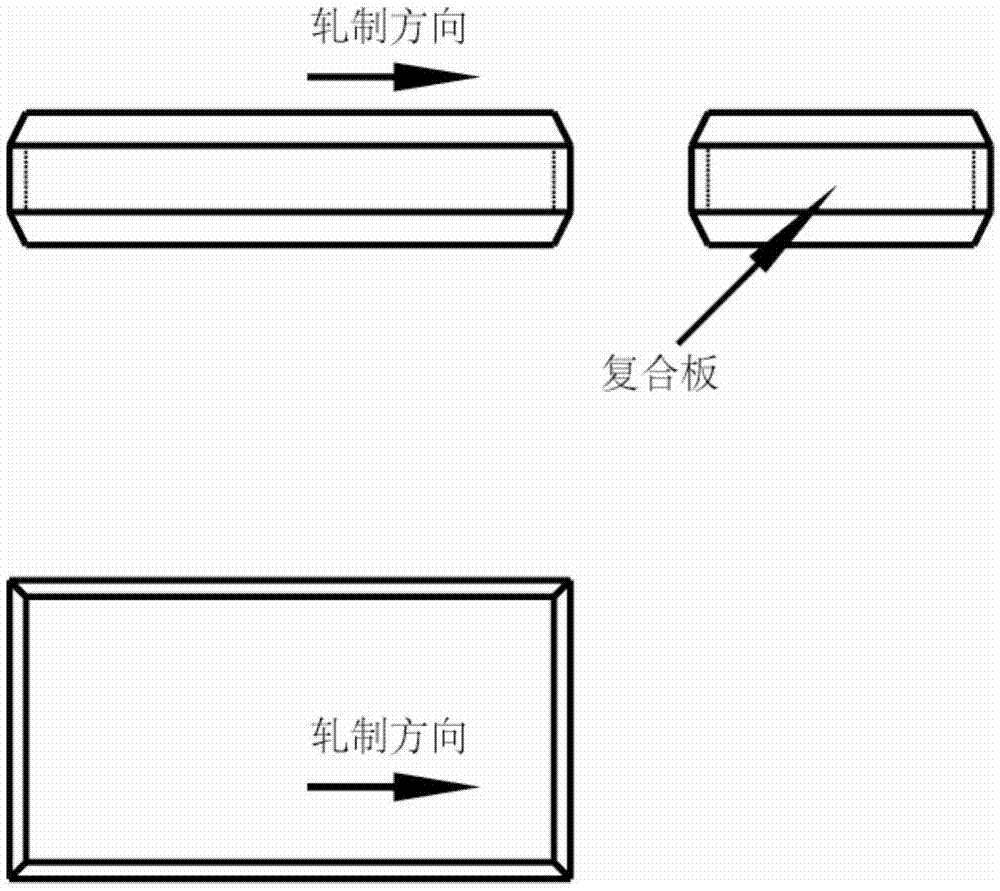

[0030] The rolling method of the present embodiment comprises the steps:

[0031] S1) Sheet annealing

[0032] First, pick the material:

[0033] Composite plate material: magnesium alloy AZ31, specification (length×width×height, the same below) 200×160×1.1mm; aluminum alloy AA6061, specification 200×160×0.9mm; titanium alloy TC4, specification 200×160×0.4mm;

[0034] Cladding layer material: aluminum alloy AA6061, upper and lower cover plates 220×180×1.1mm, frame 220×180×2.4mm, a through hole of 200×160mm is opened in the middle of the frame, and the four sides of the upper cover plate and the lower cover The four sides of the lower surface of the plate are chamfered.

[0035] Then, anneal the above materials, specifically: the magnesium alloy plate is heated to 350oC and kept for 30 minutes; the aluminum alloy plate is heated to 450oC and kept for 90 minutes; the titanium alloy plate is heated to 500oC and kept for 60 minutes; minute.

[0036] S2) Use an angle grinder to...

Embodiment 2

[0044] S1) Sheet annealing

[0045] First, pick the material:

[0046] Composite plate material: magnesium alloy AZ31, 200×16×0.9mm; aluminum alloy AA6061, 200×160×0.9mm; titanium alloy TC4, 200×160×0.2mm;

[0047]Cladding layer material: aluminum alloy AA6061, upper and lower cover plates 230×190×1.2mm, frame 230×190×2mm, a through hole of 200×160mm is opened in the middle of the frame, and the four sides of the upper cover plate and the lower cover plate The four sides of the lower surface are chamfered.

[0048] Then, anneal the above materials, specifically: magnesium alloy annealing temperature 350oC, annealing time 30 minutes; aluminum alloy annealing temperature 450oC, annealing time 90 minutes; titanium alloy annealing temperature 500oC, annealing time 60 minutes, coating material 450oC, annealing time 90 minutes.

[0049] S2) Use an angle grinder to assemble a steel brush to grind the surfaces to be compounded, that is, the two opposite surfaces between the magnesi...

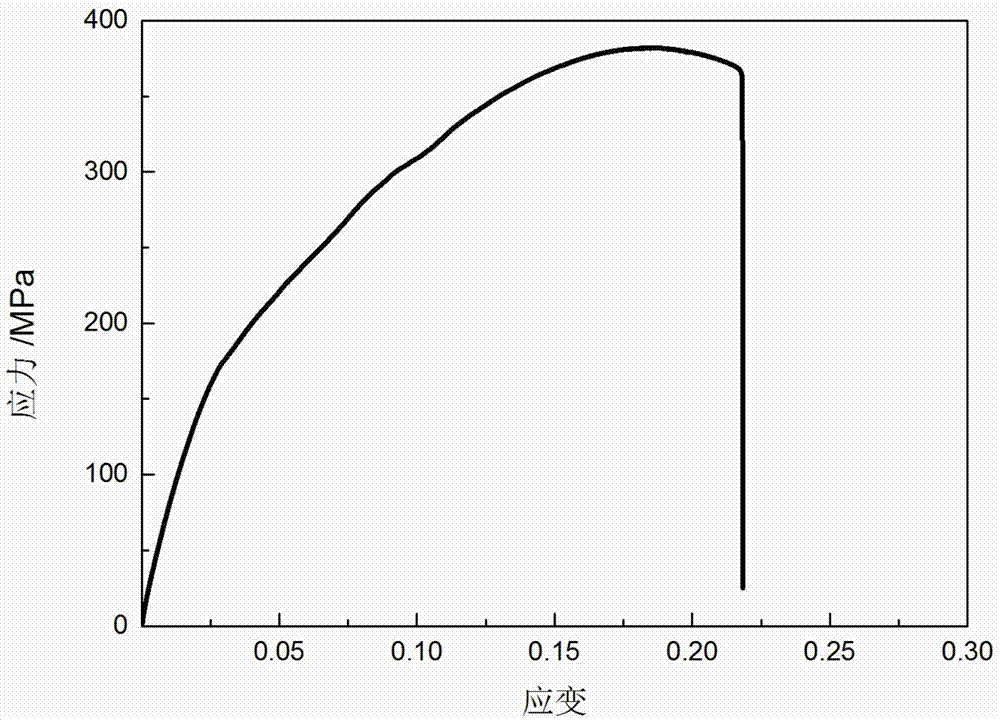

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com