Feeding device on front stand of ASSEL tube mill

A technology of feeding device and pipe rolling machine, which is applied in metal rolling, metal rolling, metal processing equipment, etc., to achieve the effect of simple structure, preventing slippage and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments, which do not depart from the scope of the present invention, and the descriptions and drawings therein are essentially for illustrative purposes, rather than limiting this invention.

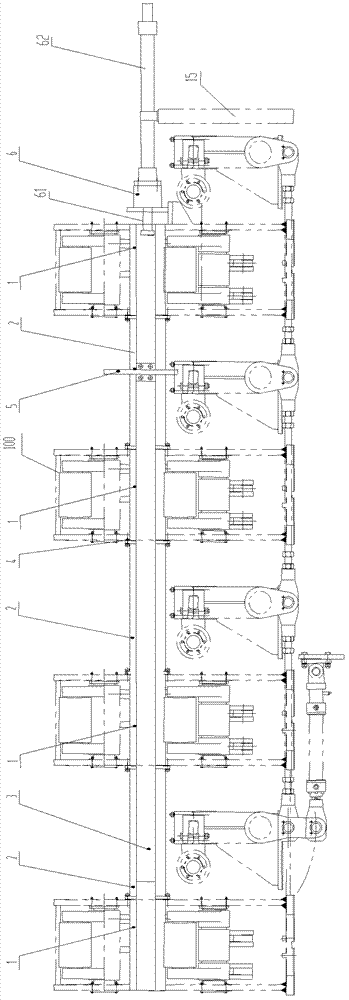

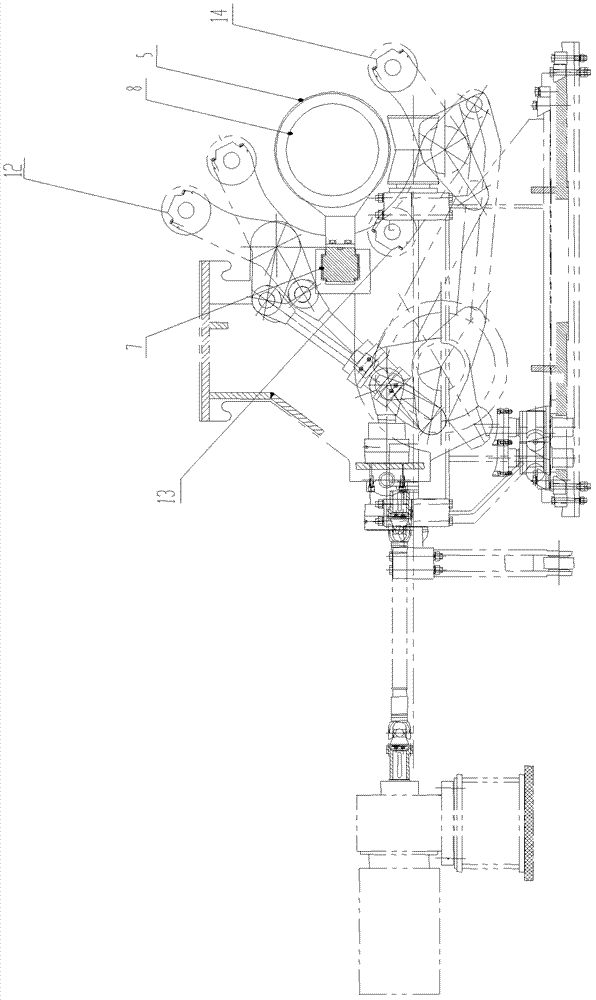

[0031] Such as figure 1 with figure 2 As shown, the feeding device at the front desk of the ASSEL pipe rolling mill according to the present invention includes a fixed rail 1, a transition rail 2, an adjustment pad 4, a push rod 3, a push head 5, a hydraulic cylinder 6, and a slide assembly 7.

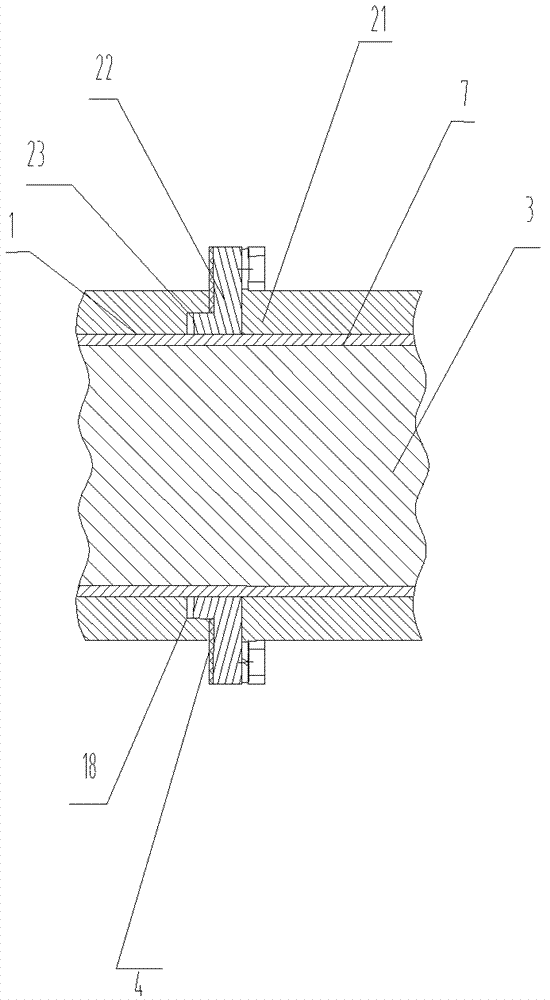

[0032] See Figure 3 to Figure 5 , The fixed guide rail 1 is a hollow shell with a C-shaped cross section, an opening 11 on the right side, and grooves 18 at both ends.

[0033] See Figure 3 to Figure 5 The transition rail 2 is a hollow shell with a C-shaped cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com