Pinch roll for pipes and bars

A technology for pinch rolls and rods, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of low contact rate, reduced rolling precision, and increased difficulty of rolling mill bite, and achieve good contact, Guaranteed contact rate and smooth bite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

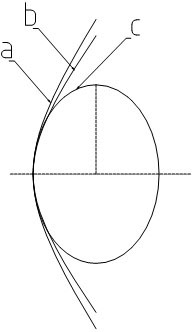

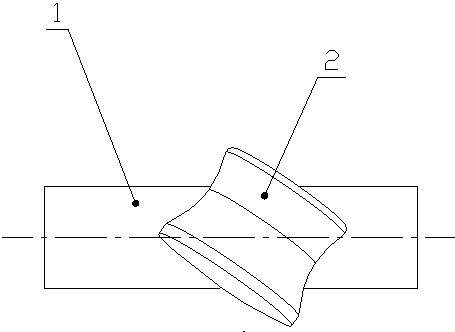

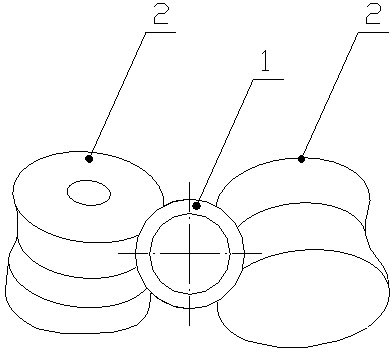

[0016] Such as figure 2 , 3 As shown, the two rollers 2 of the pinch roller device are arranged crosswise with the cylindrical blank 1, and the rollers 2 and the cylindrical blank 1 form an inclination angle α (such as Figure 4 shown). The cylindrical blank 1 is driven forward by the self-rotation of the roller 2, and the axis of the roller 2 and the intersection point of the roller 2 and the cylindrical surface of the cylindrical blank 1 are taken as a surface, and the cylindrical surface of the cylindrical blank 1 is cut with this surface, and the cylindrical blank 1 is cut to obtain an ellipse Shaped facets (such as Figure 5 shown), this ellipse edge is the best meshing curve.

[0017] Figure 4 , 5 Among them, d is the diameter of the cylindrical blank, a is the major axis of the elliptical section, b is the short axis of the elliptical sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com