Wood screw

A technology of wood screws and threaded teeth, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of reduced cutting function of cutting grooves, small screw-in resistance function, reduced contact area, etc., and achieve the goal of suppressing tensile strength Effect of lowering, reducing screwing resistance, and suppressing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

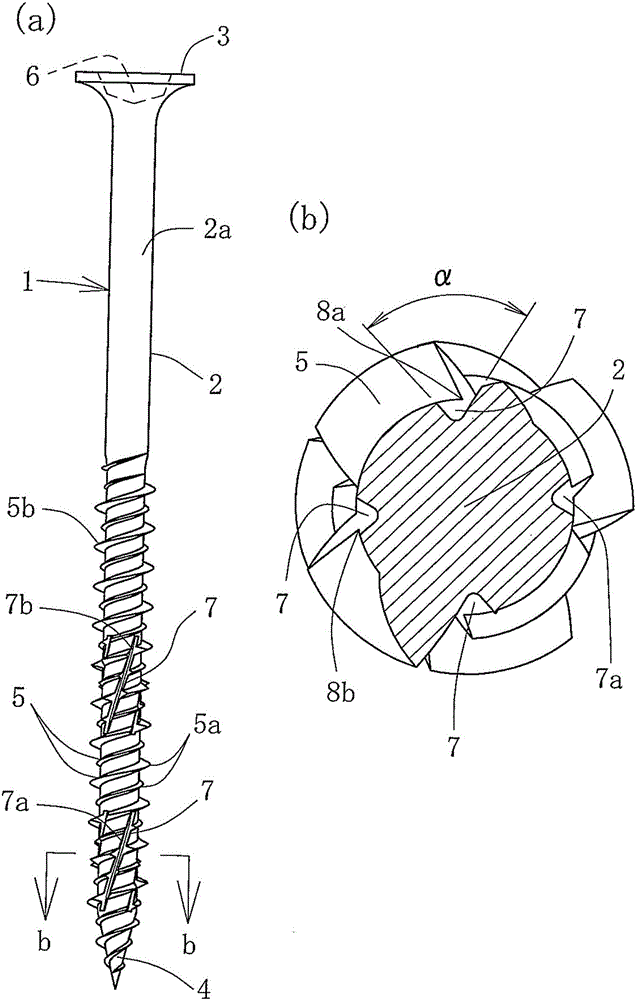

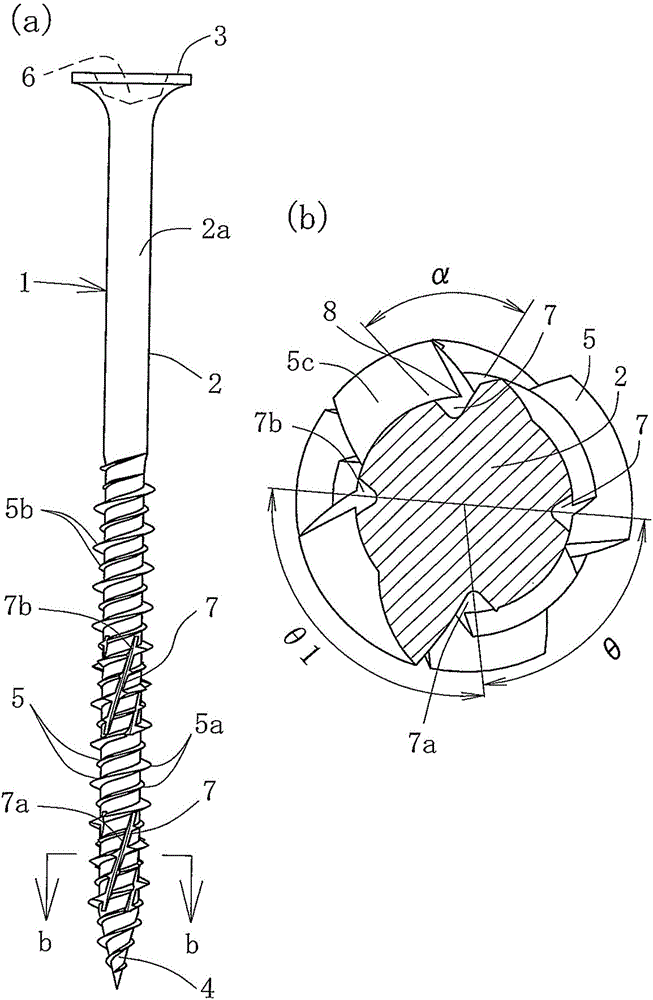

[0047] As shown in the figure, the wood screw 1 includes: a shaft portion 2 having a predetermined length and diameter, a head portion 3 provided at one end of the shaft portion, and a sharp tapered tip provided at the other end of the shaft portion 2. Part 4, on the outer peripheral surface of the above-mentioned shaft part 2 and the front end part 4, a screw thread 5 terminated in the middle of the longitudinal direction of the shaft part 2 is provided continuously from the front end part 4 to the head part 3 side, and the screw thread of the above-mentioned shaft part 2 Between the teeth 5 and the head 3 is a straight circular shaft-shaped unthreaded portion 2 a , and the head 3 is provided with an engaging hole 6 for a rotary tool.

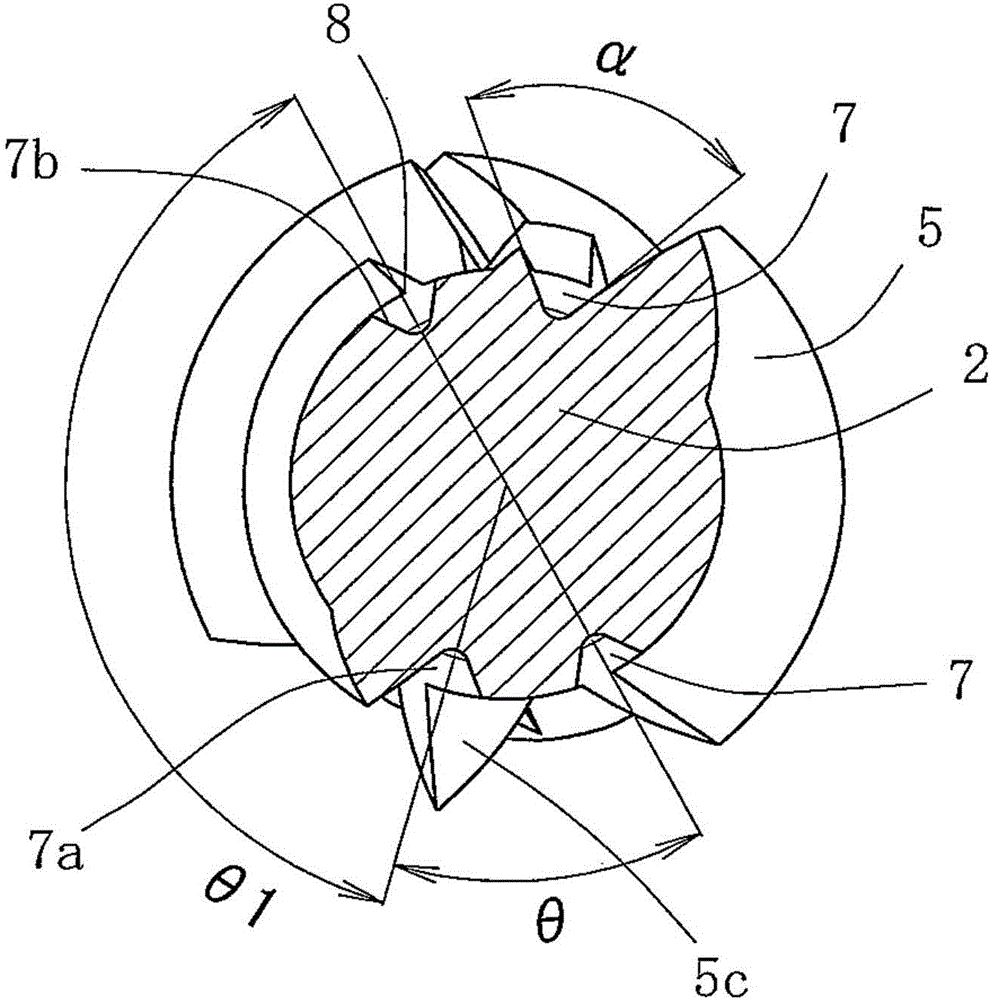

[0048] In the above-mentioned wood screw 1, a plurality of cutting grooves 7 that are longer in the axial direction of the shaft portion 2 are provided in the portion of the shaft portion 2 where the threaded teeth 5 are arranged at a distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com