Vertical mill inlet shared induction device

A vertical rolling mill and entrance technology, applied in the direction of guiding/positioning/aligning devices, etc., can solve the problems of shortening the service cycle of the guiding device, the lack of commonality of the guiding device, and prolonging the replacement time, so as to reduce the reserve of spare parts and Expenses, avoid scratch defects, reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

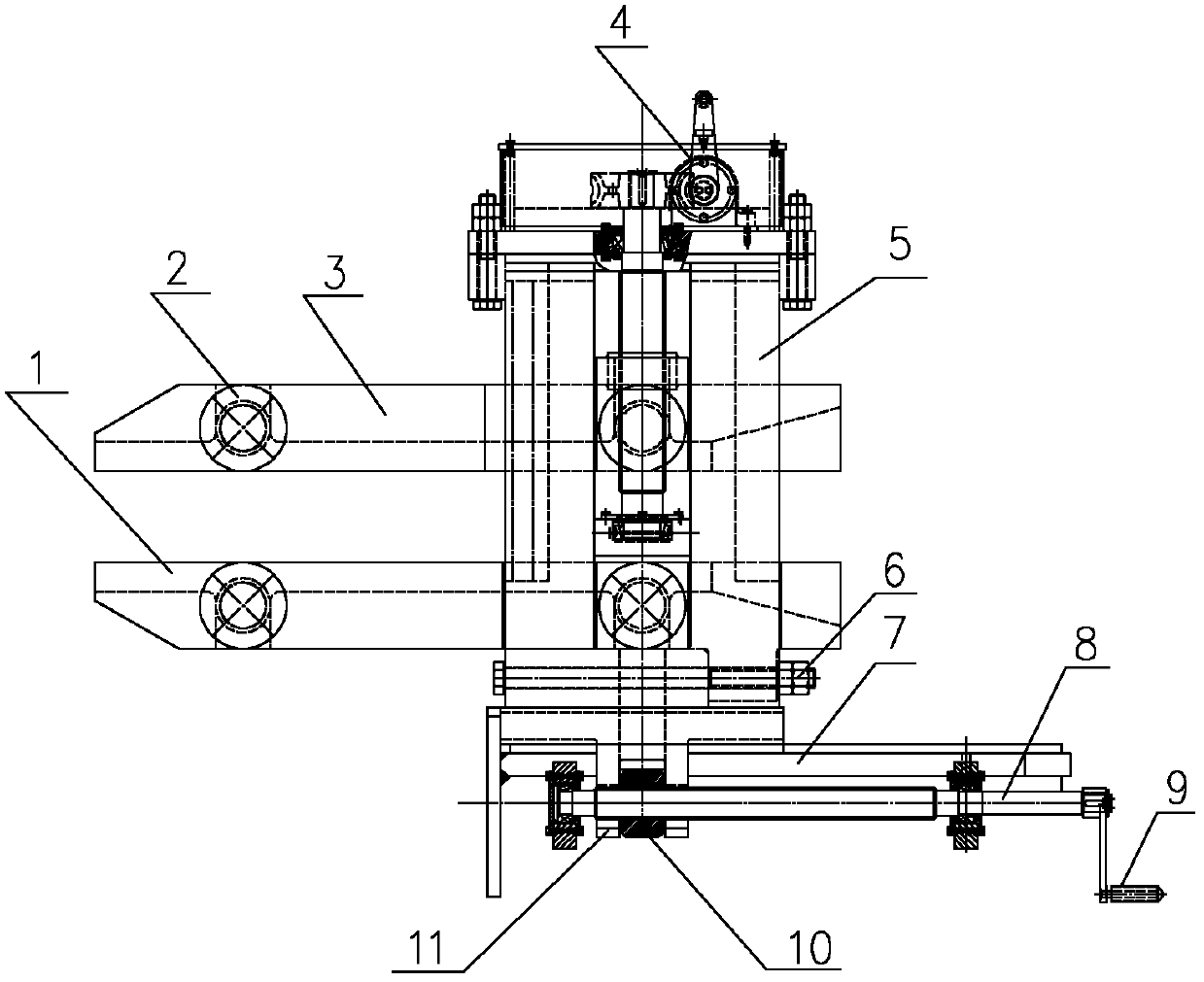

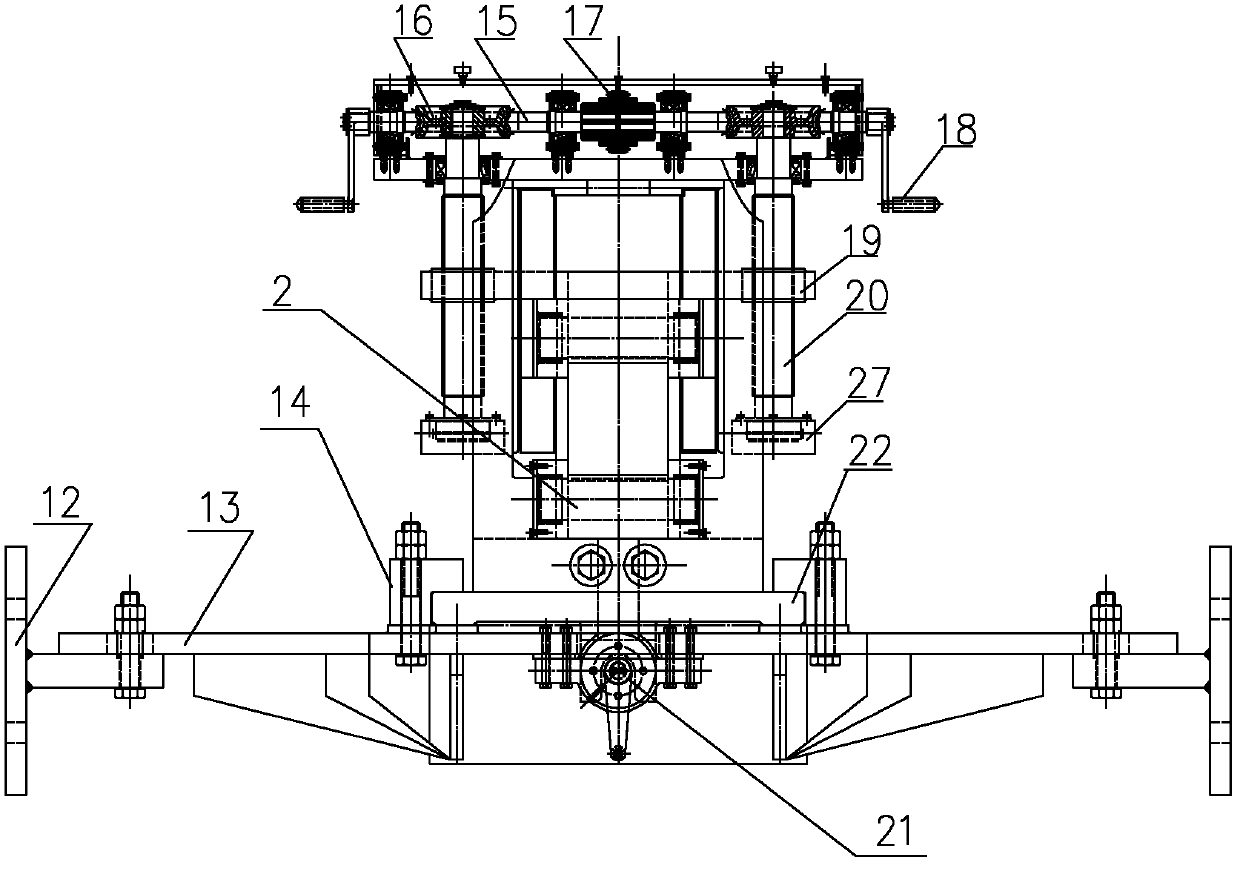

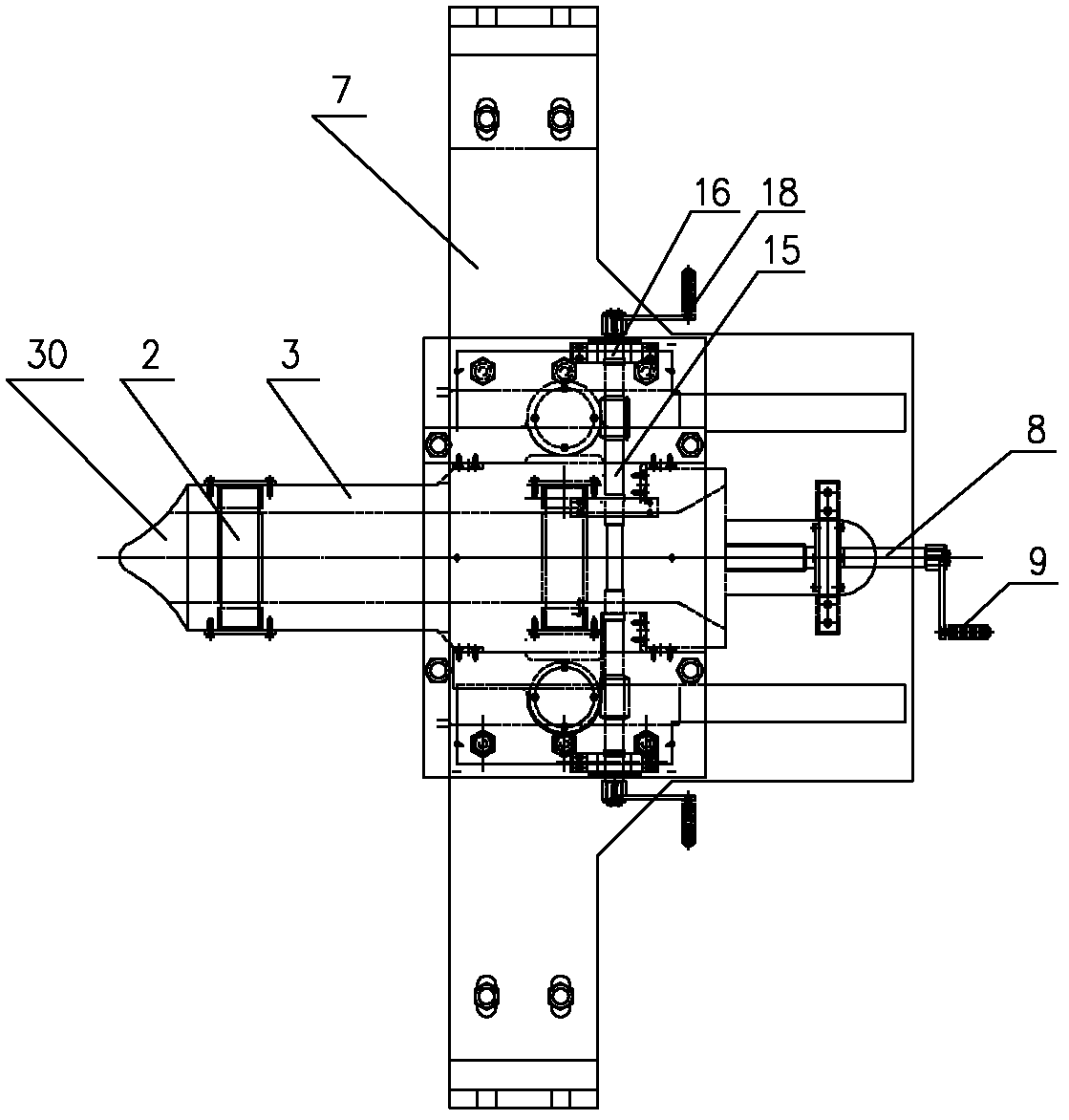

[0028] As can be seen from the accompanying drawings, the vertical rolling mill entrance shared induction device of the present invention is mainly composed of a lower support arm 1, a guide roller 2, an upper support arm 3, a guide roller opening adjustment mechanism 4, a guide body 5, a fixed bracket 7, a guide Guard body horizontal moving mechanism 21 and corresponding connector are formed.

[0029] The fixed bracket 7 as a bracket for the horizontal movement of the guide body 5 is in the shape of a "T" as a whole, and is assembled by a frame body 13 and an ear plate 12 . A limit baffle 23 is fixed on the inner side of the frame body 13, and a chute 24 is processed in the middle of the upper surface of the frame body 13, and the limit baffle 23 and the chute 24 can carry out horizontal and vertical direction adjustment to the guide body 5 respectively. limit. Simultaneously, on the upper surface of the frame body 13, there are also two inverted "L" shaped pressure plates 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com