Rolling method of small and medium shipbuilding flat-bulb steel

A small and medium-sized ball technology, applied in the field of section steel rolling, can solve the problems of backward production technology, high tooling consumption, poor surface quality, etc., and achieve the effect of improving surface quality, improving production efficiency, and reducing rolling passes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] A rolling method of small and medium-sized shipbuilding flat bulbs according to the present invention adopts a direct rolling method for rolling, and the rolling equipment includes 3-5 shifts of three-roller type steel mills, and each shift of three-roller type steel mills is divided into rows layout; the specific rolling process includes the following steps:

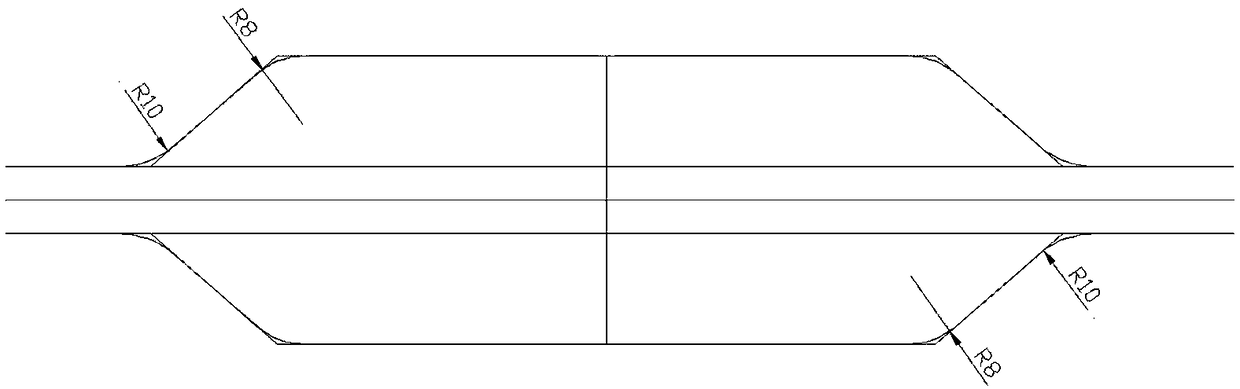

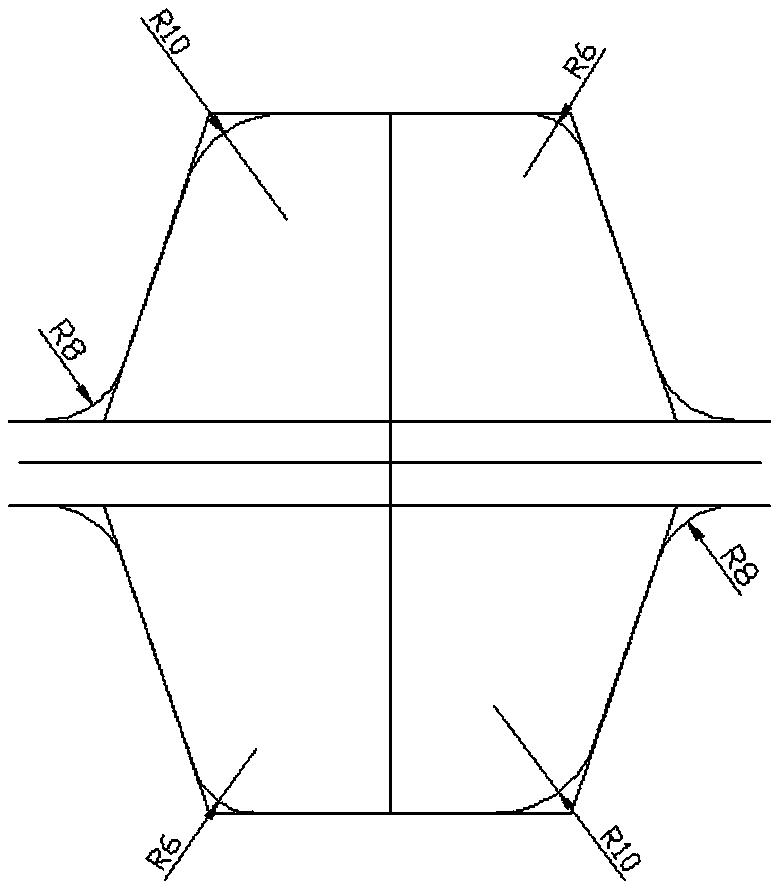

[0029] 1) Rough rolling, including several passes of rolling process; in this step, box-shaped pass rolling is completed, and the rolled piece is rolled out of a bulbous flat steel special-shaped section;

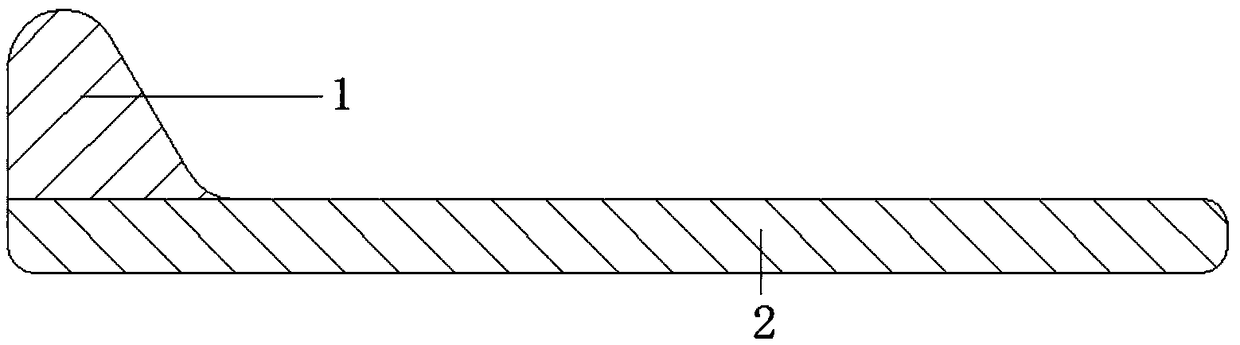

[0030] 2) Intermediate rolling, including several rolling passes; in this step, the distribution of the metal amount between the ball head 1 and the web 2 is completed; the rough-rolled special-shaped rolled piece is forced to widen by a large reduction, and it is completed at one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com