Hat shape steel rolling method and hat shape steel

A section steel and finishing rolling technology, which is applied to the hat section steel rolling method and the hat section steel field, can solve the problems of incapable of meeting the production of hat section steel, etc., so as to improve the production efficiency and rolling stability, reduce the loss, and reduce the difficulty of process design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A hat-shaped steel rolling method, the rolling process includes: heating → high-pressure water descaling → billet rough rolling → reciprocating continuous rolling → cooling → straightening;

[0041] Walking beam heating furnace can be used for heating, and the temperature of the soaking section of the heating furnace is preferably controlled at 1200-1280°C to ensure that there is no obvious black mark of the furnace bottom tube on the surface of the billet, and ensure that the soaking section time is ≥ 30 minutes. This example Among the preferred ≥ 33 minutes;

[0042] In high pressure water descaling, the working water pressure of the descaling machine should not be lower than 16MPa to ensure that the oxide scale of the billet is removed cleanly, and the running speed of the billet can be controlled at 0.5-2.5m / s, preferably 1.5-2m / s in this example;

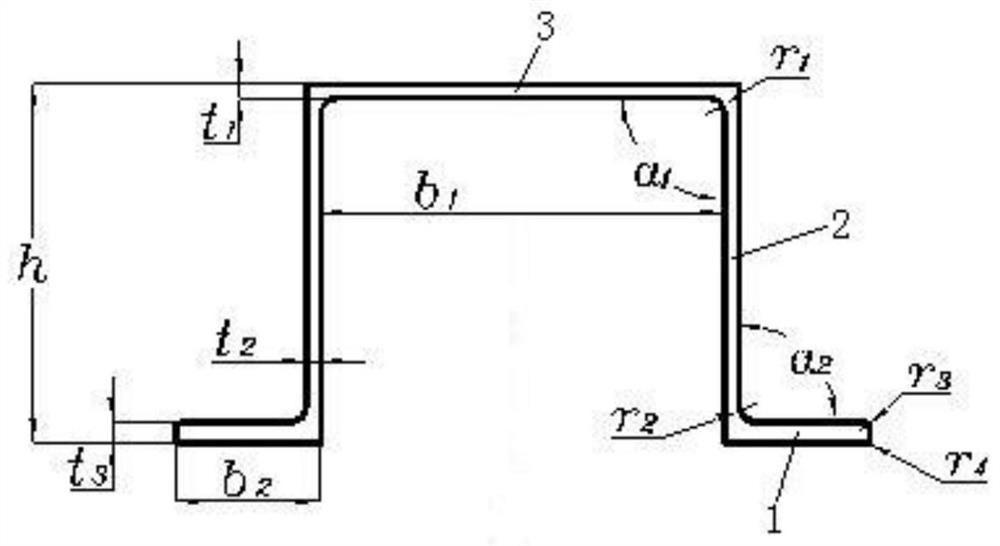

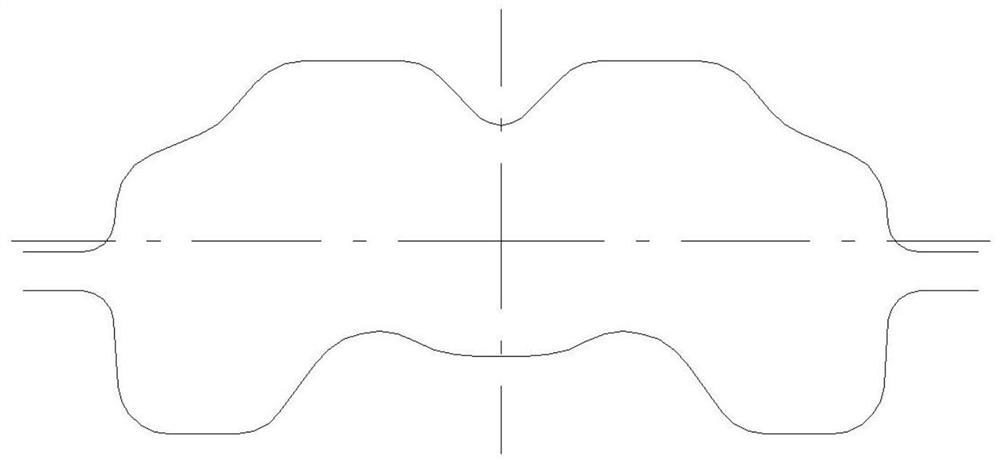

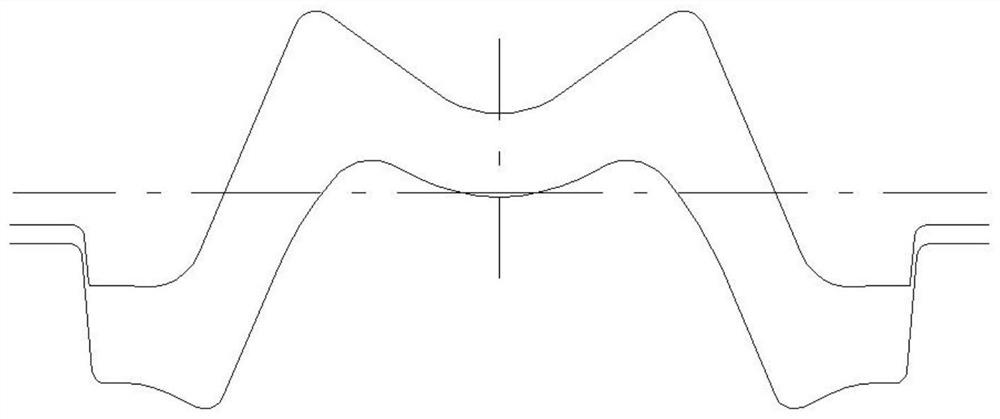

[0043] During rolling, the rolling holes shall at least include wavy flat arc-shaped pre-slit holes in the order of pa...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the rolling passes include flat arc-shaped pre-slitting holes K10, several types of cutting holes K7, several types of finishing holes K5, and several types of finishing holes in the order of passes. K3 and hot-rolled finished hole K1, other passes can be added between each pass, and the total number of passes does not need to be controlled at 11 or 12, and the producer can adjust it as needed; but in principle, it still needs to be satisfied, from The angle between the upper leg and the middle arc section of the several-type cutting hole to the hot-rolled finished hole and the slope of the side wall of the upper leg gradually decrease in the order of passes.

Embodiment 3

[0051] The difference between this example and Example 1 is that the temperature of the soaking section of the heating furnace is controlled at 1220-1280°C, and the working water pressure of the descaling machine in the high-pressure water descaling is ≥20.5MPa;

[0052] On the basis of Example 1, the arc radius of the flat arc-shaped pre-slit hole K11 and the angle between the tangent lines at both ends of the arc are as follows, β1-11: 40mm, 93.9°, β2-11: 40mm, 125.9°, β3 -11: 60mm, 96.7°, β4-11: 100mm, 150.8°, β5-11: 45mm, 118.3°, β6-11: 60mm, 153.3°, β7-11: 50mm, 130.3°, β8-11: 40mm, 128.7°, β9-11: 25mm, 77°;

[0053] The arc radius of the flat arc-shaped pre-cut hole K10 and the angle between the tangent lines at both ends of the arc are as follows, β1-10: 40mm, 112.9°, β2-10: 50mm, 108.8°, β3-10: 60mm, 89.2°, β4-10: 180mm, 160°, β6-10: 50mm, 123.1°, β7-10: 40mm, 123.1°, β8-10: 80mm, 133.6°, β9-10: 28mm, 87°;

[0054] The radii of the circular arcs and the tangent angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com