A rolling method of symmetrical spherical flat steel for large shipbuilding

A spherical flat steel, symmetrical technology, used in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of insufficient metal filling of the ball head, high labor intensity of operators, and low accuracy of web width, etc. Internal tissue defects, improving mechanical properties and mechanical properties, and controlling the effect of surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below, but it is not used to limit the scope of the present invention:

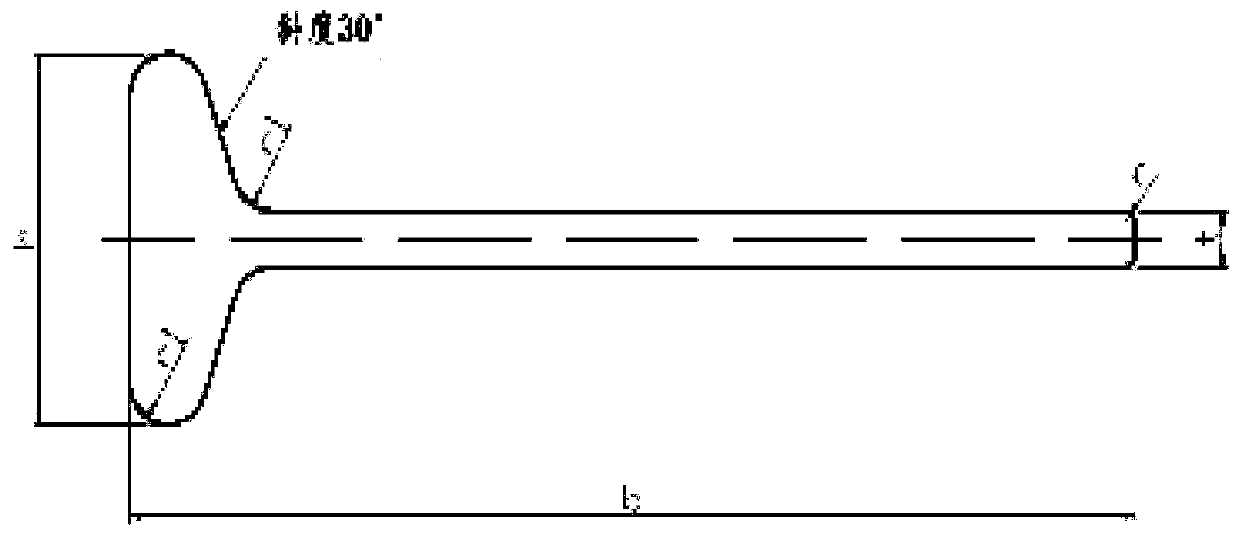

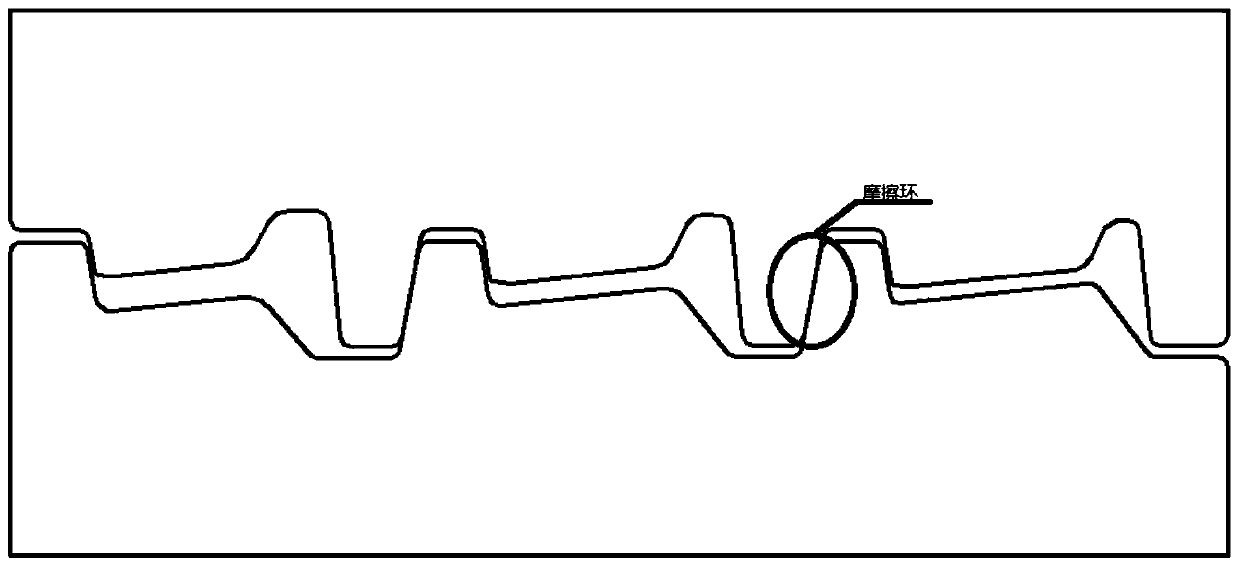

[0024] The rolling method of a kind of large-scale marine symmetrical flat bulb steel of the present invention, the symmetrical bulbous flat steel used for shipbuilding above 30# is the large-scale marine symmetrical bulbous flat steel, which is rolled by skew rolling, and the rolling equipment includes 1 carriage and two Roller profile mills, 3-5 shifts of three-roller profile mills, each rack of three-roller profile mills are arranged in rows, and the specific rolling process includes the following steps:

[0025] 1) Rough rolling, including several passes of rolling; in this step, box-shaped pass rolling is completed, and the bloom is rolled into a bulbous flat steel special-shaped section through several passes;

[0026] 2) Intermediate rolling, including several rolling passes; in this step, the distribution of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com