Control method for stable coiling of head of hot-rolled high-strength steel

A control method and head technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems that the head of the strip cannot be completely guaranteed, and achieve the effect of improving the bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

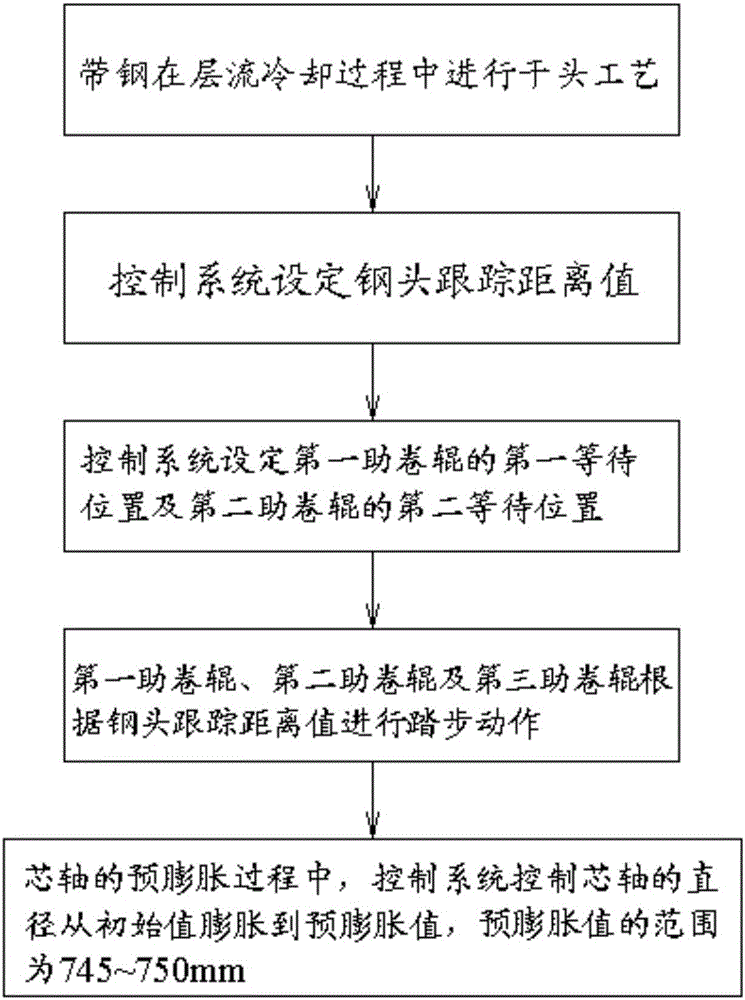

[0053] S1: The strip is subjected to a dry-heading process during the laminar flow cooling process, and the part within 1m from the strip head is not sprayed with cooling liquid.

[0054] S2: The control system sets the steel head tracking distance value, that is, the processing unit sets the first set value to be equal to the distance that the strip head passes from the pinch roll to the first winding roll plus 150 mm; the second set value It is equal to the distance that the strip head passes from the first roll-up roll to the second roll-up roll plus 150 mm; the third set value is equal to the distance that the strip head passes from the second roll-up roll to the third roll-up roll Add 150mm to the distance.

[0055] S3: The control system sets the first waiting position of the first winding-assisting roller and the second waiting position of the second winding-assisting roller, that is, the processing unit sets the distance between the first waiting position of the first ...

Embodiment 2

[0059] S1: The strip is subjected to a dry-heading process during the laminar flow cooling process, and the part within 2m from the strip head is not sprayed with cooling liquid.

[0060] S2: The control system sets the steel head tracking distance value, that is, the processing unit sets the first set value equal to the distance that the strip head passes from the pinch roll to the first coil roll plus 220mm; the second set value It is equal to the distance that the strip head passes from the first roll-up roll to the second roll-up roll plus 220mm; the third set value is equal to the distance that the strip head passes from the second roll-up roll to the third roll-up roll Distance plus 220mm.

[0061] S3: The control system sets the first waiting position of the first winding-assisting roller and the second waiting position of the second winding-assisting roller, that is, the processing unit sets the distance between the first waiting position of the first winding-assisting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com