Roller of three-roller planetary rolling mill

A technology for planetary rolling mills and rolls, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of billet deformation, unspecified, and unstable pitch uniformity of rolled pipes, etc., to achieve extended service life, pitch Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

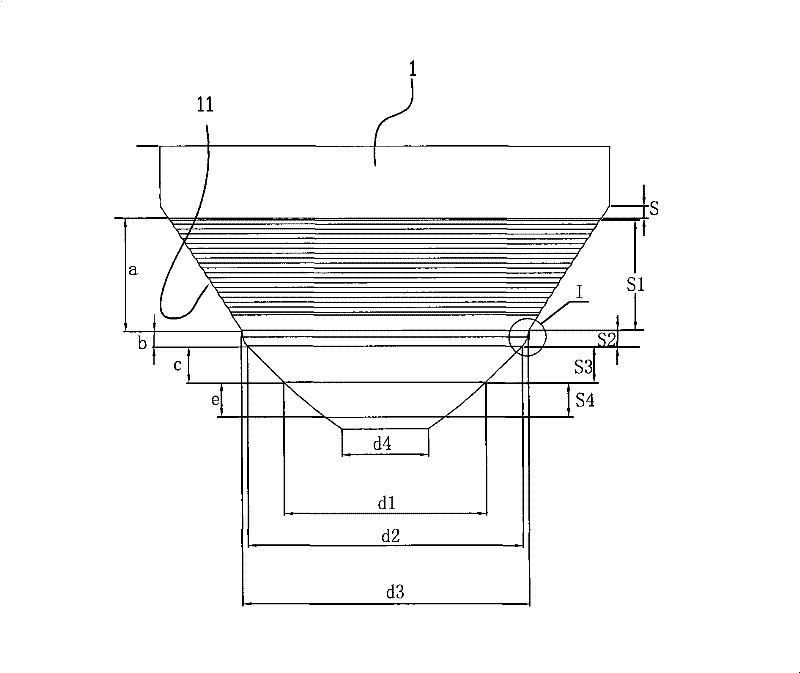

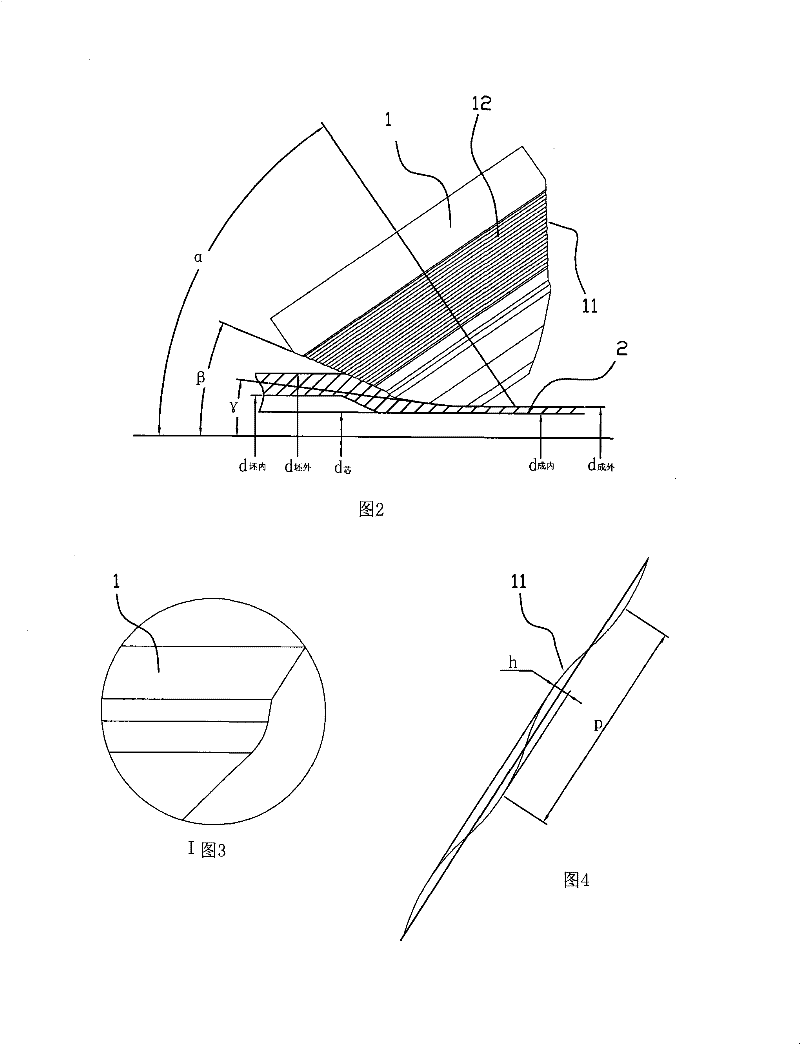

[0022] Such as Figure 1 to Figure 4 As shown, the roll of the three-roll planetary rolling mill in this embodiment, the roll 1 is basically conical, and the roll 1 is divided into five areas from the tail to the head, which are sequentially: feeding area S, deformation area S1, process In zone S2, sizing zone S3 and discharge zone S4, on the conical surface of roll 1 in deformation zone S1, there are annular concave-convex lines 12 distributed radially and at intervals, and the axial projection of the concave-convex lines 12 is The oblique line 11 formed is a sinusoidal curve, and the axial projection is the vertical axis of the roll rotation axis. The vertical distance h between the peak and the concave corner of the concave-convex lines 12 is 0.5 mm, and the width P of the concave-convex lines is 2.932 mm, and the intersections between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com