Backstop high-expansion expansion bolt

An expansion bolt and expansion technology, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problem that the axial outward and inward movement of the bolt cannot be restricted at the same time, and achieve the effect of high expansion force and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

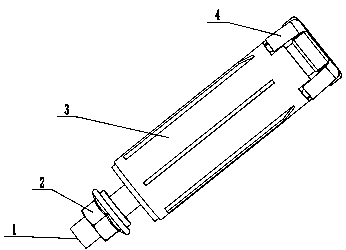

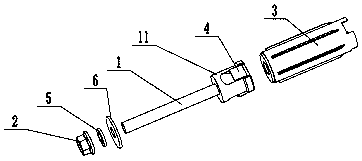

[0029] see Figure 1-Figure 5 It is a kind of anti-retraction high-expansion expansion bolt in one embodiment, including:

[0030] The bolt body 1 is provided with a push block 11 at its front;

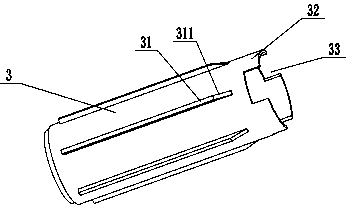

[0031] The outer casing 3 is arranged outside the bolt body 1;

[0032] The nut 2 is matched with the bolt body 1; a spring pad 5 and a washer 6 are also arranged between the nut 2 and the outer sleeve 3;

[0033] Wherein, a clamping block 4 is installed on the pushing block 11, a clamping plate 32 and a pushing groove 33 are arranged at the front of the outer sleeve 3, and the movement of the pushing block 11 makes the clamping block 4 rotate and expand the clamping plate 32 at the same time. open, so that the clamping block 4 and the clamping plate 32 can be bidirectionally locked. For the expansion bolts of the existing structure, the tail of the outer casing expands to form a trumpet-shaped opening and the wall is clamped. When the bolt is pulled outward by an external force, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com