Apparatus and method for surface measurement

A technology of surface measurement and surface features, applied in measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve the problems of inability to obtain four measurement line data, and difficulty in determining the valve seat circle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

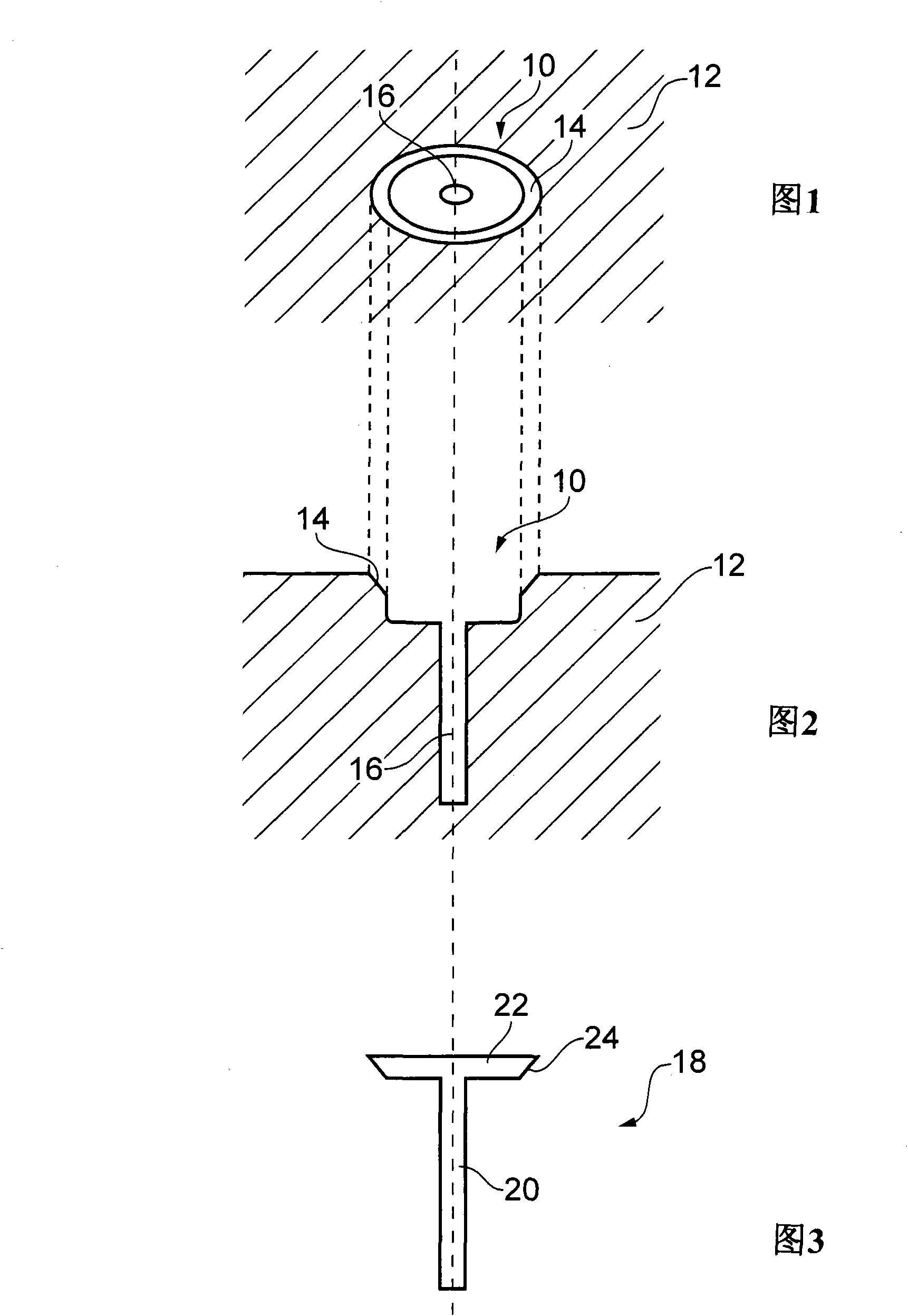

[0048] figure 1 and figure 2 A perspective view and a cross-sectional view of the valve seat are shown, respectively. image 3 A side view of the valve disc for insertion into the valve seat is shown. These valves are of the type found, for example, in the cylinder heads of automobile engines.

[0049] The valve seat 10 is positioned in the valve body 12 . The valve seat includes a conical surface 14 defining a recess in the valve body which opens into a cylindrical bore 16 . The valve disc 18 includes a cylindrical stem 20 sized to fit snugly in the cylindrical bore of the valve seat. At one end of the cylindrical rod 20 is provided a disc member 22 having a conical surface 24 on its peripheral surface. The disc members of the valve seat and the valve disc have corresponding conical surfaces 14 and 24 which form a seal when the valve disc is inserted into the valve seat.

[0050] For the valve to work well, there needs to be a good fit between the seat and the conical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com