Tertiary panel-shape closed-loop control method

A technology of closed-loop control and flatness control, which is applied in the direction of contour control, adaptive control, general control system, etc., and can solve the problems that are not suitable for the development of flatness control technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0144] Embodiments of the invention are described below with the aid of the drawings:

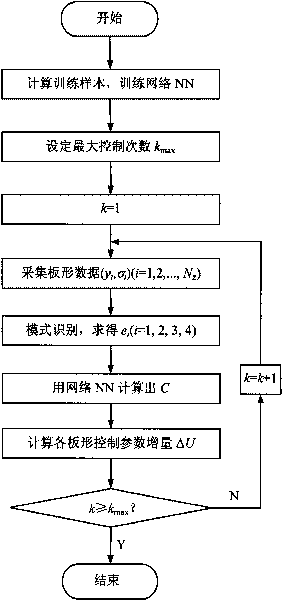

[0145] A kind of plate shape closed-loop control method that contains three times plate shape proposed by the present invention, its calculation process is as follows figure 1 shown, including the following steps:

[0146] (a) Collect shape data (y i , σ i )(i=1, 2, ..., N z ), where N z is the number of measurement points, σ i is the coordinate y i shape deviation at

[0147] (b) Use the plate shape pattern recognition method containing three plate shapes to collect the plate shape data (y i , σ i )(i=1, 2, ..., N z ) for pattern recognition to identify the characteristic parameter e of the plate shape i (i=1,2,3,4);

[0148] (c) Establish a shape adjustment influence coefficient matrix to quickly calculate the network NN, and use the network NN to calculate the influence coefficient matrix C according to the current rolling state;

[0149] (d) from e calculated in step (b) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com