System for cold roll profiling profiles having variable cross-sections

A cold-rolled forming, cross-section technology, applied in the direction of metal rolling, etc., can solve the problems of cross-section deviation, difficulty in compression and stretching of metal sheet materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

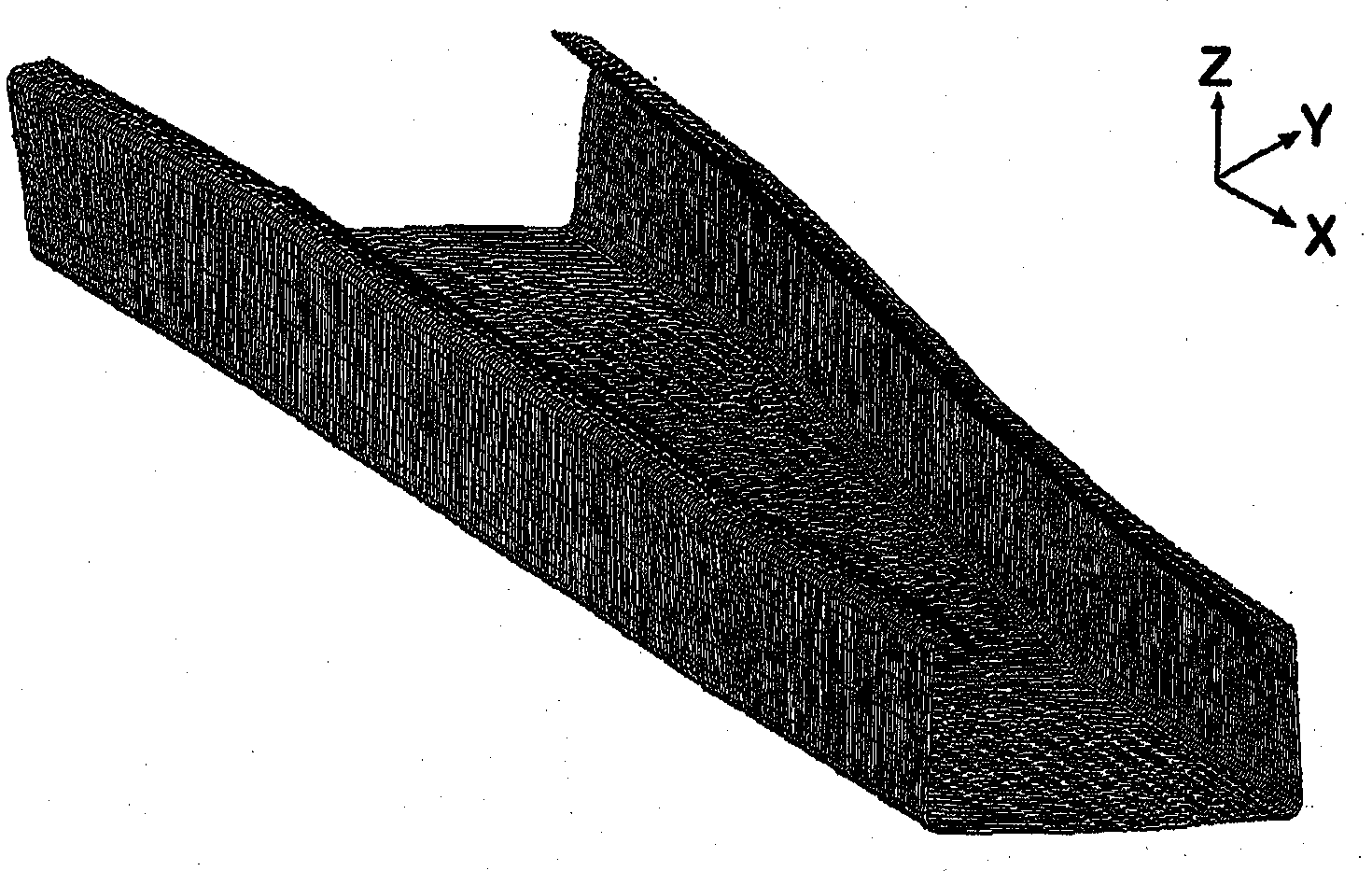

[0019] A known (not shown) device for cold roll forming of profiles of variable cross-section comprises: a unit for cutting the metal strip along its width; a drive unit for the metal strip and a forming unit.

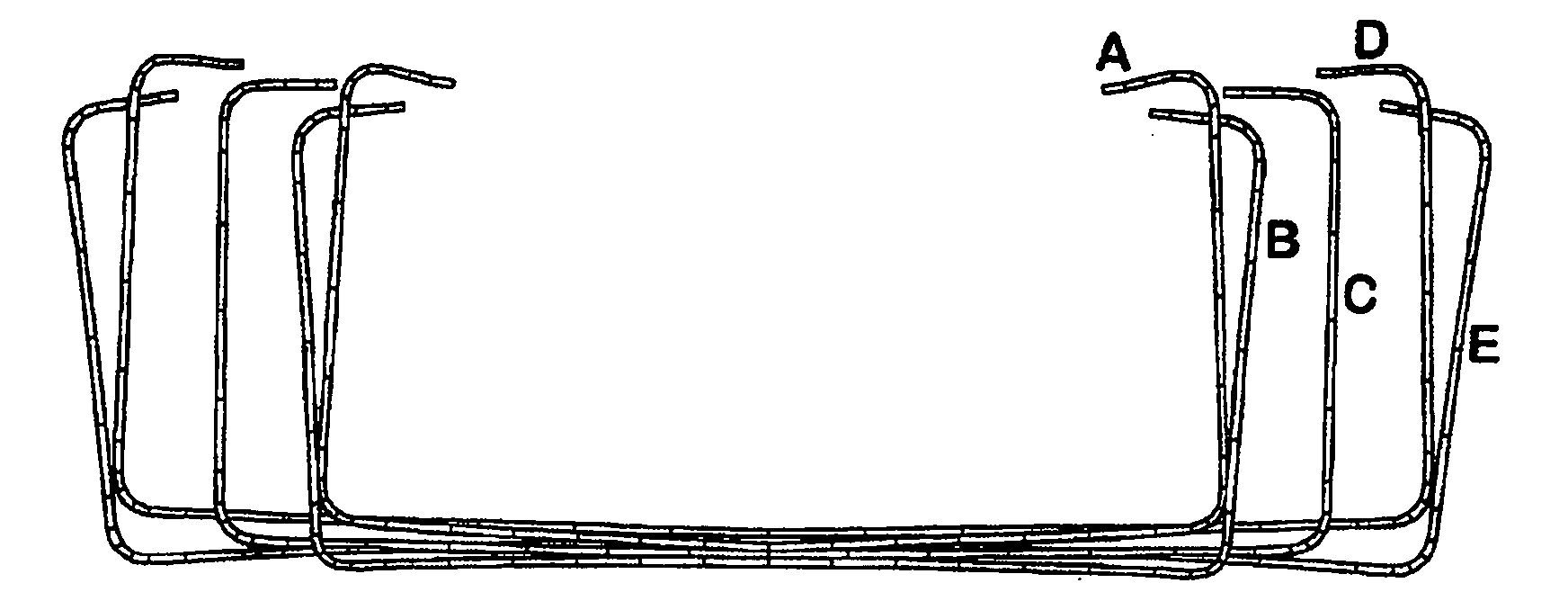

[0020] The forming unit comprises the known row of adjusting supports each having a roller support comprising a pair of rollers between which the metal sheet strip is guided along its length. The roll holders are translated transversely to the length of the sheet metal strip during cold roll forming and are moved and moved rotationally about the axes of the roll holders in order to deform the sheet metal strip into profiles of variable cross-section. The rollers of the roller stand are usually axis-parallel to each other, but the axes of the rollers can also be slightly inclined to each other with diameters that can vary in the longitudinal direction.

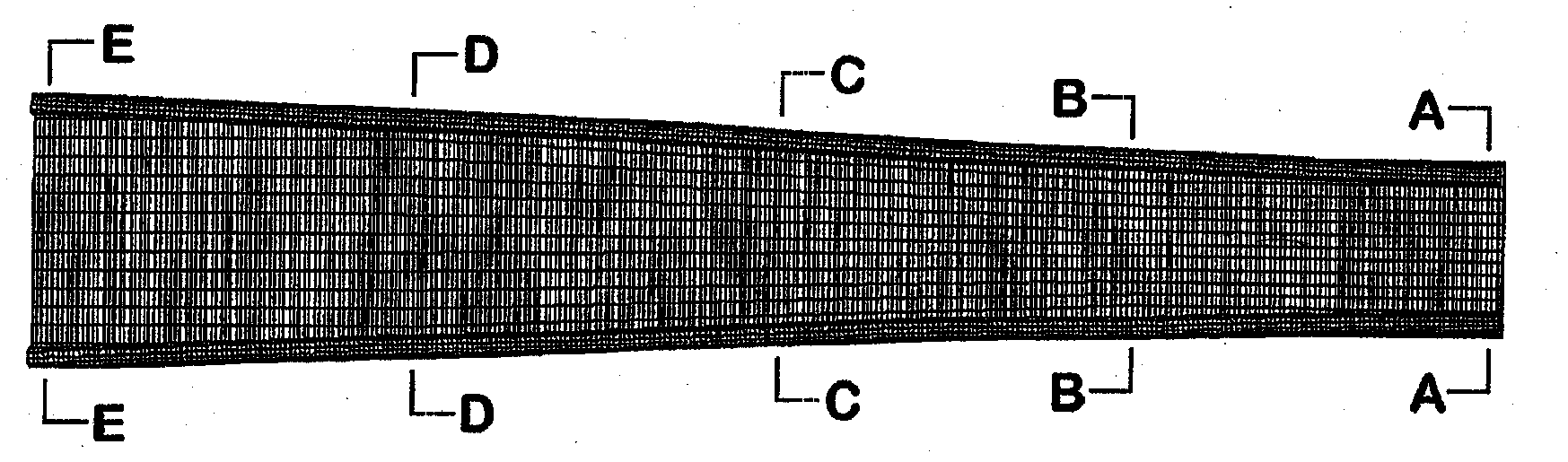

[0021] The following description is given with the aid of a variable-width profile, wherein the adjustment bracket is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com